Recruiting the Best and Brightest @ Pratt & Whitney

As it ramps up production of a new jet engine, Pratt & Whitney needs to do more than shore up its supply base, it is changing its recruiting tactics, according to its senior director of supply management.

It’s an exciting and historic time to be at Pratt & Whitney, which is in the midst of its greatest jet engine product ramp since the 1980s.

We have a backlog of more than 8,000 engine orders, including announced and unannounced firm and option engines for our revolutionary PurePower® Geared Turbofan™ commercial engine family, and are the sole power plant provider for the F-35 Lightning II with our F135 engine, the most technologically advanced fighter engine ever produced.

With this growth comes many challenges.

To meet our increased customer commitments, we’re growing our supply base at new levels to provide the majority of the parts we need to build our industry-leading engines.

As our supplier numbers grow, the number of new employees we need to support them grows as well.

Read the Article: How Pratt & Whitney Is Managing Its Future Growth and Supply Chain Suppliers

As a result, we’re actively recruiting and hiring the best and brightest talent to ensure success in managing our Global Supply Chain (GSC) network.

Having advanced through the ranks of the GSC organization, I may be biased, but I do believe my organization offers new hires an environment uniquely challenging and filled with opportunities for development and growth.

Roles in GSC provide opportunities to strengthen analytical and problem-resolution skills, build accountability and strategic ownership, foster relationship management and practice cross-functional engagement by expanding professional networks.

Given our efforts to find and hire exceptional people to fill critical GSC positions, as well as other key roles throughout the company, it’s no surprise that the manner in which we recruit, train, develop and work to retain them has changed as our business has changed.

Historically, we’ve had a reactive recruiting function based on a “post and pray” model. That strategy, however, doesn’t identify the passive job seekers who don’t know about us and what we have to offer. Our new strategy revolves around finding the best talent, selling our brand and presenting our candidates with the best opportunities.

We have moved beyond just posting positions on the Web and attending national conventions. One of our most successful tools has been the development of “Super Days,” during which 50 to 80 recruits come to our East Hartford, Connecticut, headquarters to participate in an exciting schedule of events to familiarize themselves with the company, its products, services and culture. Many of those who attend wind up joining our team.

And our employee referral program, in place for several years and which offers a cash bonus to employee’s identifying those we successfully recruit, is seeing increased prominence. Qualified professionals like those in our organization know other qualified professionals, and it’s a competitive advantage when our own people identify talented candidates to join us.

In addition to the myriad training and development programs we offer all Pratt & Whitney employees, specific to our organization is the Global Supply Chain Development Program, an entry-level, two-year rotational program in four functional areas, each six months in duration. Experience gained in the program provides new employees with a comprehensive understanding of the GSC business and its relationship to Pratt and Whitney’s overall performance and customer satisfaction.

The rotation’s four assignments are in the areas of Supply Management, in which participants join the value stream team responsible for the purchase of a group of engine parts;

- Supplier Quality Assurance, which gives them an understanding of the company’s quality systems and procedures and key quality performance metrics;

- Materials Management, where they learn product scheduling and inventory management and their relationship to on-time delivery and customer satisfaction; and a “specialty” assignment which could range from working in our newly created;

- Command Center, where participants help manage material flow for our production engine build, to;

- Global Workshare, where they assist in improving and managing the company’s outsourced processes and vendor deliverables to internal customers.

This comprehensive rotational program not only gives participants broad knowledge across the supply chain network, but also identifies areas they’d like to pursue as they begin their Pratt & Whitney careers.

UTC, Pratt & Whitney’s parent company, also offers Supply Chain University (SCU), a mix of online and classroom curriculum offered in several languages that allows supply chain professionals across the corporation to tailor their learning based on their personal and professional goals. SCU not only provides individuals with the skills they need to advance their careers, it also ensures that common work practices, like standard work, which are transferrable throughout the corporation, are shared by all employees. The intent is to leverage economies of scale to ensure each supply chain organization operates under the same rules and procedures.

Over time, through the university, we should see proficiency levels improve and at a faster clip. SCU allows our supply chain employees to become less pigeon-holed, provide transferrable skills and open their eyes to a broader career path.

Recruiting and hiring the best new supply chain talent is only half of the challenge. Retaining them so they become the company’s future subject experts and leaders is the other half. Pratt & Whitney has consistently provided competitive salaries and benefits to its employees. But today’s employees are looking for much more – a sense of belonging and connectivity to where they work.

To address this, the company offers a number of work/life programs. We sponsor eight Employee Resource Groups (ERGs), which embrace diversity and give employees the opportunity to become more engaged by providing a venue for shared interests, expectations and contributions. The groups range from Emerging Professionals to the African American Forum, which I’m honored to lead as president. ERGs are open to all employees and provide opportunities to expand professional networks, learn about different cultures, develop careers and gain leadership experience. Across UTC, there are some 75 groups with 19,000 employee participants.

ERGs can serve to retain valuable employees in addition to helping them connect with fellow employees and provide them with new skills. I know a six-year Pratt & Whitney quality engineer supervisor who recently said, “The events we held and relationships I formed as part of the East Hartford-based Emerging Professionals group played a big part in why I wanted to stay with the company.”

Our ability to build and maintain an inclusive work environment is critical to our continued success. As a leader at Pratt & Whitney, I help foster an inclusive and engaging culture that values everybody’s opinions. It is our employees’ unique perspectives and innovative ideas that keep us ahead of the competition. In addition, ethical behavior is our foundation for everything we do, which is why we have earned a reputation for integrity among our employees, customers, shareholders, suppliers and communities around the world. In the end, I believe people want to work for a company that values everyone’s contributions and operates with the highest integrity.

The GSC organization has been rewarding to me for a variety of reasons. First, no one day is like the one before, we have a very dynamic culture, my work allows me to make a business impact, helping to set the strategic vision of the organization, and it provides me with a great opportunity to give back and develop others. Maya Angelou said it best: “When you learn, teach.” I take pride and passion in coaching and developing employees every chance I get.

I often tell new employees they need to do three things: excel at everything you do and let your work speak for itself; constantly enhance your craft, through continuous training and development; and don’t be afraid to accept “messy” assignments as they’re an opportunity to make a difference right away. I’ve always been an advocate for “your attitude can determine your altitude.”

As Pratt & Whitney’s engine technology has evolved over its more than 90 years of existence, so, too, have the skills and talents we look for in our employees to meet the demand of an ever-changing world. Today, our GSC organization employees need to fully understand the business, possess exceptional communications skills and, in many cases, be visionary leaders. We are confident that the tools we provide them today and in the future will ensure not only the continued success of our company, but their personal success as well.

About the Author: Shornda Cadore is senior director of Supply Management for the Global Supply Chain organization at Pratt & Whitney, a United Technologies Corporation (UTC) company. She can be reached at [email protected]. For more information, visit United Technologies Corporation - Pratt & Whitney Division.

Editor’s Note: Without question, companies are in the midst of remaking their supply chains to meet the new demands of today’s market. At the same time, companies like Walgreen’s are having to rethink their recruiting and training strategies to find the talent they need to meet those new demands. Those two challenges are coming together at aerospace leader Pratt & Whitney, which is doubling its production capabilities to meet the demand for a new jet engine while simultaneously recruiting new talent. Supply Chain Management Review invited Shornda Cadore, Pratt’s senior director of supply management, to discuss some of the strategies it is employing. Bob Trebilcock, editorial director.

Broadening of Needed Skills for a Job

Without clearly identified workstations, workers are increasingly likely to hold a series of jobs.

As a result people develop their ability to hold several positions in a factory or warehouse, thereby becoming more flexible.

Even low skilled work (handling, data entry, etc.) are evolving from simple execution to taking actual responsibility for part of the production process.

This growing demand for a variety of skills is particularly clear in the logistics sector where handlers have become drivers, order handlers, warehouse managers, etc.

A study by Sascha Becker and Marc-Andreas Muendler found that as a result of globalisation, the average German job expanded from entailing fewer than two tasks in 1979 to more than seven in 2006.

In addition, “as whole industries adjust and new ones are born, many occupations will undergo a fundamental transformation. They will change the skill sets required in both old and new occupations in most industries and transform how and where people work, leading to new management and regulatory challenges.

Companies are more and more looking for new (soft) skills related to new jobs. Research highlights that tasks and jobs requiring emotional and personal skills, such as persuasiveness, creativity, strategic approaches, analytical capacity, communication skills, innovative thinking, flexibility and social skills, are facing increasing demand.

Such skills have been shown to contribute to job creation, for example the Organisation for Economic Co-operation and Development (OECD) demonstrated that young innovative firms that possess such soft skills have been responsible for almost half of the jobs created among OECD countries.

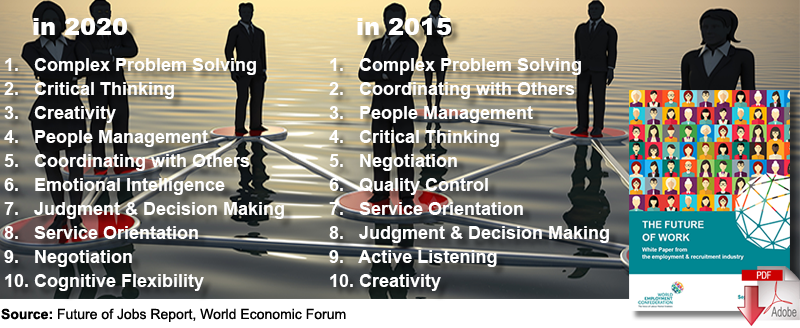

Top 10 Skills (Future of Jobs Report, World Economic Forum)

Download the White Paper: The Future of Work

Article Topics

ASCM News & Resources

Supply Chain Stability Index sees ‘Tremendous Improvement’ in 2023 Supply Chain Stability Index: “Tremendous Improvement” in 2023 The Right Approach for Supply Chain Education The reBound Podcast: Innovation in the 3PL supply chain Supply Chain’s Top Trends for 2024 Require Talent Investment for Success Resilience Certificate Now Available from ASCM ASCM conference highlights importance of geopolitics in the supply chain More ASCMLatest in Supply Chain

Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Ranking the Best Countries for Private Business in EMEA Frictionless Videocast: The Importance of Water at the U.S./Mexico Border with Commissioner Maria-Elena Giner, International Boundary and Water Commission Why are Diesel Prices Climbing Back Over $4 a Gallon? Plastic Pollution is a Problem Many Companies are Still Ignoring Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws 80% of Companies Still Unsure How to Best Leverage AI, Study Finds More Supply Chain