Opel Reduces Assembly Tool Costs By Up to 90%

Opel, Europe’s 3rd largest automotive manufacturer, is slashing manufacturing tool production costs by up to 90% using its Stratasys 3D Printers, as well as 3D printing assembly tools in less than 24 hours.

Opel was the third-largest passenger car brand in the European Union in 2014, and together with Vauxhall, sold more than a million cars.

With efficient production crucial to its success, Opel’s International Technical Development Center is 3D printing a range of manufacturing and assembly tools to advance the production of its iconic ‘Adam’ hatchback car.

These assembly tools are used to precisely attach different components to the car, such as the rocker molding and roof spoilers, align the iconic ‘Adam’ lettering on the rear-side window, as well as assemble the glass and retractable roofs.

“Besides the cut in tool production time and considerable cost reductions, customized tools are a third important benefit achieved with 3D printing. We are now able to produce more complex shapes than we could via conventional manufacturing. This crucially allows us to adapt the tool to the worker and the specific car,” says Sascha Holl, Virtual Simulation Engineer - Tool Design at Opel.

Opel’s Stratasys 3D printed assembly tools are used to align the iconic ‘Adam’ lettering on the car’s rear-side window

Since 3D printing its manufacturing tools, the company involves its assembly-line workers in the design process to improve efficiency.

This allows operators to evaluate concepts, using their experience to highlight any potential issues before committing to the production of the final assembly tool for each specific car component.

With Stratasys 3D printing, any required design iterations to the Opel manufacturing tools are easily accommodated in a matter of hours, eliminating costly iterations further along the production process.

“Cases like Opel emphasize the massive impact that low risk, high-reward 3D printed parts – such as manufacturing tools – can have on production efficiency,” says Andy Middleton, President, Stratasys, EMEA.

“The capability to produce such items on-demand at a reduced costs can significantly accelerate time-to-production and give businesses that competitive edge. Combine that with the ability to customize tools efficiently, as well as create complex geometries, and you can see why Opel is indicative of the way in which additive manufacturing is transforming our customer’s production operations.”

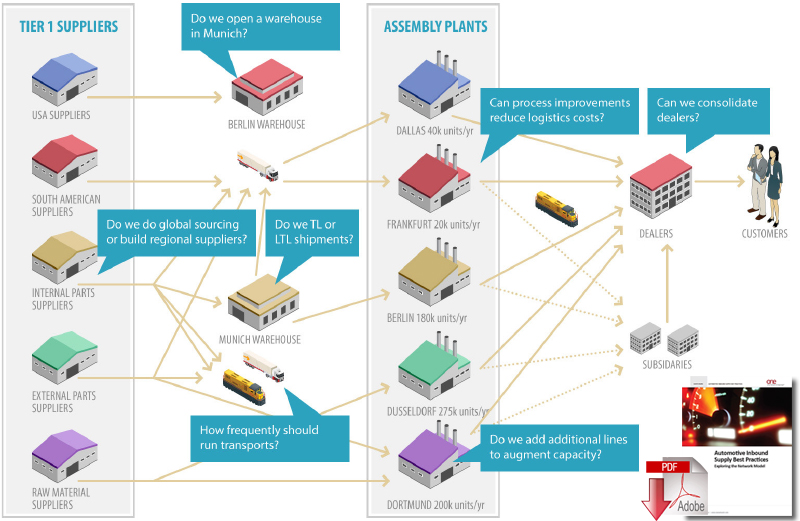

Related: Inbound Logistics Requirements for the New Automotive Supply Chain

Download the White Paper: Automotive Inbound Supply Best Practices

Article Topics

Stratasys News & Resources

McLaren Plans to 3D Print Racing Car Parts Five Ways 3D Printing Is Transforming the Automotive Industry The 3D-Printed Athletic Shoe Race and What It Means For Your Retail Based Supply Chain Opel Reduces Assembly Tool Costs By Up to 90% Manufacturing’s Next Act - Industry 4.0 Amazon Files Patent for 3D Printing Delivery Trucks 3D Printing Promises to Transform Manufacturing & Supply Chains More StratasysLatest in Business

Ranking the Top 20 Women in Supply Chain TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process U.S. Manufacturing Gains Momentum After Another Strong Month More Business