NPI: Building a Path to Faster Production and Greater Profitability

Today’s new production introduction (NPI) landscape is dynamic and fast-paced, and many manufacturers are struggling to keep up.

What’s weighing them down? Traditional enterprise resource planning (ERP) and product lifecycle management (PLM) solutions that simply weren’t designed to manage NPI from end to end.

Other inhibitors include the “silos” that prevent effective communication between brand owners and suppliers that manufacture their products.

We recently partnered with Supply Chain Management Review to create a special report devoted to the topic of NPI.

We explore the key challenges that innovative companies face in trying to streamline the NPI process, and examine how centralized software platforms are helping many companies to achieve greater productivity.

To give you an idea of what you’ll learn in this publication, I’d like to present a few highlights from the feature article, “Streamlining the New Product Introduction Process” – as well as from my interview with Pierfrancesco Manenti, vice president of SCM World:

Without a core solution to help guide NPI, the responsibility of managing the process from end-to-end falls somewhere between the manufacturing firm’s IT and business departments—neither of which is well equipped to handle it from end-to-end.

It’s a vicious cycle: IT throws ERP or PLM at the problem and comes up short—very short, in fact. The operations department then tries to pick up the pieces, but it’s a painstaking process. In the end, their efforts miss the mark, too.

A better solution? A systemized approach to NPI that includes all manufacturing, design, or supplier collaboration data required to build first prototypes of new products. (This is especially critical for today’s outsourced supply chains.)

The approach includes setting up and managing workflows that ensure the right steps are taken at the right time—and the right people are kept informed about progress all along the way. Closed-loop feedback is essential to this approach because product design and the manufacturing process are intertwined.

When NPI is managed effectively, companies can gain a significant competitive advantage; but when it’s not, this can be a huge setback for a business.

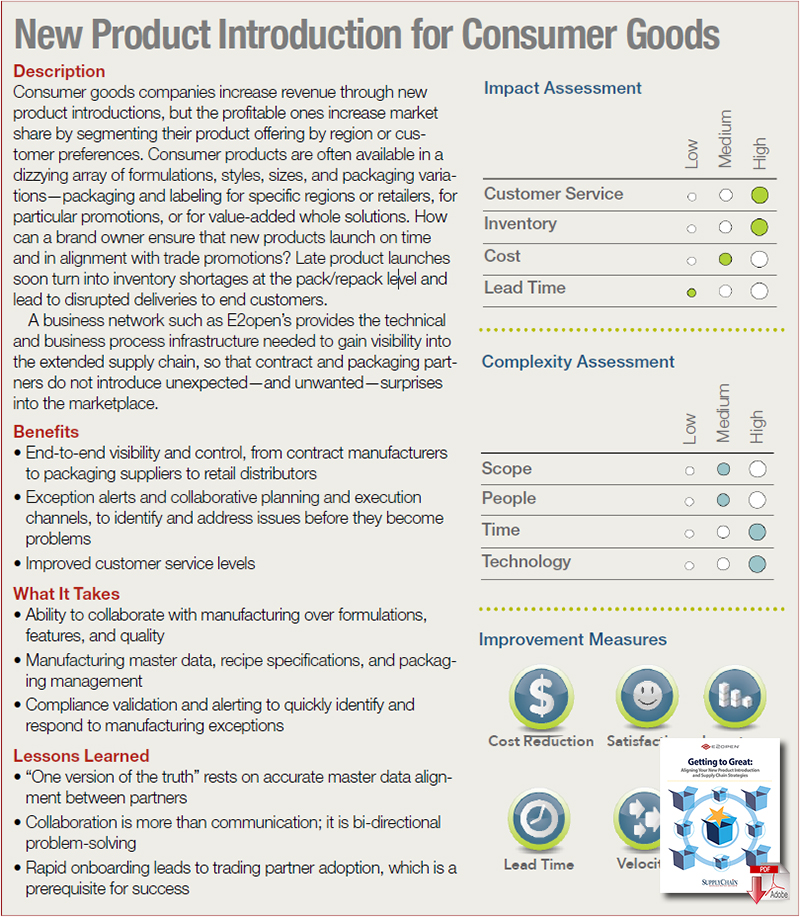

A poorly managed NPI process leads to inventory shortages and disrupted deliveries to end customers due to late product launches or launches that are not in alignment with trade promotions. Conversely, companies that take the time to establish solid NPI processes supported by technology can expect to experience productivity improvements of up to 40 percent within their manufacturing operations.

Which industries are finding success with NPI? According to SCM World’s Manenti, the high-tech and consumer product (CPG) industries are more advanced in their efforts to achieve a more structured NPI process. “I think the reason why [these industries] are more mature is that they really feel the pressure from consumers,” he said.

Manenti explained that consumers “have completely changed the ways they purchase products” in recent years due to their use of social media, e-commerce, and mobile technology: “They can edit an order, select a new product, or discard a product all from their tablets. It is all very rapid.”

He pointed to discrete manufacturing industries such as aerospace and automotive, and chemicals and process industries, as having less advanced NPI processes.

I asked Manenti how he sees the NPI process affecting companies with hybrid supply chains, or those with mixed internal manufacturing and external outsourced manufacturing, which are very common today. He said “breaking internal organizational silos” remains a key issue for many companies, especially in their extended supply chain. “The vast majority of companies in any industry—and particularly in industries like high-tech or fashion, which typically rely very heavily on contract manufacturers—have the challenge of integrating their suppliers,” he said.

Manenti added that many companies are likely to face difficulty in making sure NPI is well managed through their supply chain, especially as they continue to look to outsourcing to reduce costs and complexity in manufacturing. “Our recent research points out that brand owners need to become the customer of choice of their key suppliers and subcontractors,” he said. “It is absolutely fundamental for a customer to make sure that their key suppliers bring innovation to them and not to their competitors.”

Related: Tight Coupling of Enterprise Resource Planning to Supply Chain Planning - A Hoax?

Article Topics

E2open News & Resources

E2open President and CEO Farlekas Provides Logistics Trends and Themes Overview E2open Transportation Management Solution to Simplify Your Logistics Supply Chain Disruptions and the Next Normal for Logistics in 2023 Outsourced Quality and Sustainable Manufacturing in a World of Disruption Mitigating Supply Chain Disruption in the Wake of Severe Weather and Disasters Uber Freight & E2open to Provide Real-time Transportation Rate and Capacity Options Tracking and Reducing Transportation Emissions More E2openLatest in Supply Chain

How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? FedEx Announces Plans to Shut Down Four Facilities U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Most Companies Unprepared For Supply Chain Emergency More Supply Chain