New Supply Chain Optimization Opportunities

If your supply chain underutilizes intermodal rail – a transportation solution that offers cost savings and diversifies your access to capacity solutions – then your company could be paying the costs of a sub-optimized freight network.

The start of a new year is a time to reflect on the past and set goals to make the most out of the upcoming year.

With peak season over, and budgets finalized, supply chain managers are looking back on the challenges and successes of 2015 and seeking out opportunities to grow and improve their organization’s supply chain for 2016.

Below are some Supply Chain New Year’s resolutions supply chain managers should consider in order to improve and optimize their transportation networks in the new year:

Improve supply chain health and lose sub-optimized freight

Sub-optimized freight moving exclusively via truck when it has an intermodal rail alternative can result in increased transportation costs and decreased resource efficiency. An astounding 96% of shippers have sub-optimized freight weighing down their supply chains.(1)

Losing this sub-optimized freight provides multiple benefits, including gaining access to an alternative, scalable capacity solution that can deliver cost savings up to 40%. Twice a year, supply chain managers should analyze the health of their freight network in order to identify and lose the sub-optimized freight they may have packed on last year. For a fresh start identifying freight that is prime for intermodal conversion, request a complimentary Highway to Intermodal Rail analysis.

Resolve to cut costs and increase savings

Setting financial and budgetary goals are always at the top of New Year’s resolutions. Transportation expenses account for over 60% of supply chain costs, so this is a great place to start when looking for cost savings. Supply chain managers can take a leadership role within their organization by identifying cost-saving measures such as consolidating less-than-truckload freight to full-truckload moves and converting eligible freight from the highway to intermodal rail.

Achieve a better highway/rail balance

Just as people try to manage their work-life balance, a supply chain’s modal selection should be balanced. When supply chain managers rely on a single mode of transportation, like truck, they open their supply chains up to the risk of a single point of failure. Incorporating intermodal rail into a supply chain provides options and helps the supply chain adapt to unforeseen capacity crunches.

Related: Helping the Broncos & Panthers Deliver Their Goods

Give back

Companies of all sizes are integrating sustainability into their supply chains. As the global community puts a greater emphasis on going green and lowering carbon emissions, supply chain managers can help their organizations do their part by converting freight to intermodal rail. Moving freight by rail instead of truck can reduce greenhouse gas emissions by 75 percent.

Challenge old beliefs

New Year’s resolutions are really about learning from the past to improve for the future. Challenging old beliefs and being open to new ways of doing things is an important part of growth and sustained success. This year, supply chain managers should resolve to rethink their outdated perceptions and beliefs around the use of intermodal rail. For instance, did you know that freight moves as short as 500 miles should be evaluated for intermodal rail?

Advances in rail infrastructure and efficiencies have made shorter lengths of haul eligible for intermodal conversion. Intermodal rail fits into modern supply chains, allowing shippers to realize cost-savings, secure additional capacity and create sustainable growth for tomorrow Get the facts on today’s intermodal.

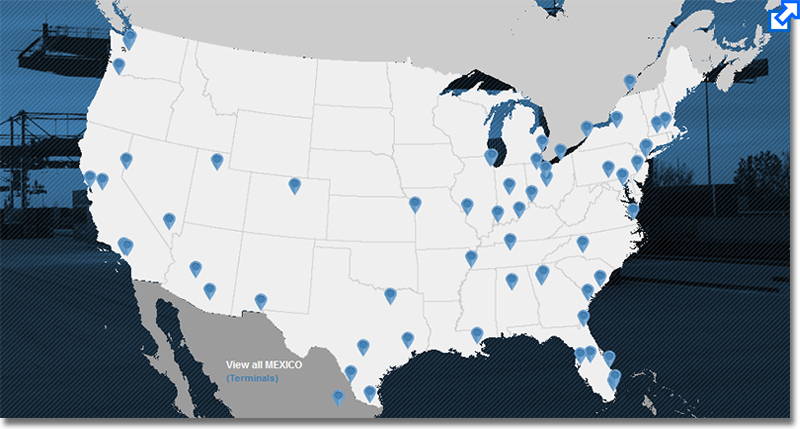

Explore new territories

People often vow to break out of their comfort zones, travel more and explore new territories at the start of a New Year. Supply Chain managers should incorporate this thinking into their networks for 2016. Exploring new modal options, intermodal lanes and identifying new optimization opportunities for their freight networks can help supply chain managers built out a well-rounded transportation network. Supply Chain managers should visit CSXT Intermodal’s interactive network map to see which intermodal trips they would like to plan for their supply chains this year.

(1) Based on all shipper truckload files analyzed in 2014 by the CSXT Intermodal H2R Optimizer

Article Topics

CSX News & Resources

Signs of progress are being made towards moving cargo in and out of Baltimore Top CSX executive places a sharp emphasis on railroading as a career path and service at NEARS Intermodal innovation? Crisis averted on U.S. railroads, with carriers and unions reaching tentative agreements CSX’s acquisition of Pan Am Railways is a done deal Baltimore breaks ground for double-stacking 126-year-old tunnel in ‘absolute game-changer’ CSX executive discusses railroad trends and themes at NEARS conference More CSXLatest in Transportation

Baltimore Bridge Collapse: Impact on Freight Navigating Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Nissan Channels Tesla With Its Latest Manufacturing Process Why are Diesel Prices Climbing Back Over $4 a Gallon? Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws The Three Biggest Challenges Facing Shippers and Carriers in 2024 Supply Chain Stability Index: “Tremendous Improvement” in 2023 More Transportation