MRO vending machines gain in popularity

Industrial vending machines are increasingly being used to stock, track, dispense and replenish MRO inventory. Here’s how it works.

A worker stands in front of a vending machine, swipes a card, keys in a specific product ID code on a keypad, and then waits patiently for the machine to go through a series of motions and dispense the item. He reaches down to grab the item, which isn’t a bag of potato chips or a candy bar, but a pair of leather gloves. Donning the gloves as he walks back to his workstation, he’s ready to get back to work.

This scenario is playing out across more factory floors these days as companies look to rein in costs while creating more “accountability” for maintenance, repair and operations (MRO) product inventory. Rather than just stocking shelves and allowing employees to retrieve and manage their use of tools, fittings, personal protective equipment (PPE), and other commonly used MRO goods, companies are using vending machines to stock, dispense and track these items.

The machines can be set up to require swipe or “code” access to obtain the MRO goods, and they can be configured to restrict access to certain products only accessible to authorized users of the consumables and supplies. Gaining in popularity, the machines are currently being used by about 24% of companies, according to Peerless Research Group’s MRO Study earlier this year. An additional 38% of respondents plan to explore the use of vending machines for their cleaning supplies, lightbulbs, nuts, bolts, screws, oils, lubricants and other MRO products over the next two years.

Charles DeBerry, director of services for America at Kennametal, says the growing interest in MRO vending machines is largely being driven by the need for accountability—or, knowing who has what tool or item at what time, how it’s being used, the point at which it is returned, and when it’s going to be available for the next person. Using the machines’ sophisticated software, supervisors can then generate reports that can be reviewed to ensure the materials are issued to the right workers and for the appropriate purposes.

“When people know they have to be more accountable for what supplies or tools they take out of the storeroom, they’re going to be a bit more careful about making sure they only take an item when it’s really needed,” says DeBerry. Kennametal’s ToolBOSS, for example, helps companies improve MRO inventory control; downsize existing, centralized tool crib operations; reduce the amount of time it takes for machine operators to locate required tools; and capture, compare and trend tooling costs associated with the part produced. Such data helps identify problem areas and opportunities for continuous-improvement efforts.

“When most people hear the term vending machine they think about potato chips and candy bars—the coil-type machines we’ve all seen in the break room or the car dealership,” DeBerry explains. “Those machines have their place, of course, but ToolBOSS is designed with drawers and is highly configurable—from the smallest items (e.g., screws and fasteners) all the way up to very large tools.”

Reducing errors, improving productivity

One of the most fundamental keys to running an efficient and cost-effective plant is having the right tool in the right place at the right time. While the cost of a milling or turning insert may range from a few dollars to a significant investment, not having that tool available when needed can shut down an entire production line or more, resulting in missed delivery dates and lost profits.

“Vending can help reduce the inventory requirement at the plant because managers gain direct visibility to what they have on hand,” says DeBerry, who sees the machines’ reporting feature as being particularly valuable in the MRO space, where missing goods and stock-outs are fairly common. When an employee needs a specific lubricant to get a machine back up and running, for example, there’s no time to scour the plant, chasing down the last person who used it.”

And when control levels and accountability go up, says DeBerry, MRO spend goes down. Saved time and improved productivity are added bonuses. For example, when employees don’t have to walk over to the main MRO store to pick up the parts or supplies they need—and when they instead just use a vending machine at the point of use—they can get back to work faster.

“In the past, someone may have had to shut down a machine, taken that 10-minute walk, gotten hung up at the coffee station, and then talked to a few friends along the route,” DeBerry says. “Because they can withstand pretty harsh work environments, vending machines can be positioned closer to the users, thus eliminating those non-productive minutes or hours.”

They’ve come a long way

Industrial vending machines have improved significantly over the last 10 years thanks to advancements in technology and their applicability in the manufacturing and distribution environments. The fact that supervisors and managers want better control of their MRO inventory and spend is driving demand for the units, as is the desire to know “who took what item and at what time,” says Leonard Bashkin, president of SecuraStock, maker of the CribTrack.

“People want to be able to control access to the products, and both the end user and the distributor that’s stocking the machine want advanced reporting capabilities on the machines’ inventory,” says Bashkin, noting that in many cases it’s the product distributors that place and stock the machines at the customer site. And while the earliest vending machines weren’t very well suited for MRO inventory (i.e., most were designed to dispense food and beverages), new iterations of the machines can handle a much wider range of products.

“Every one of our machines is made to be able to dispense any product—from hard hats to oxygen tanks to batteries to bolts,” says Bashkin. “And you can put all of those items into the same machine, store bulk or packaged goods, and then dispense them however you want to.” In the interest of saving time and improving worker productivity, the machines do their jobs in less than 15 seconds, are made with shatterproof glass, and can manage 200+ SKUs.

Bashkin says CribTrack machines offer a reduced cost of ownership equal to five times less measured as total cost to buy and support machine vending a certain number of a SKU, and that the company is working to whittle down that cost even further. “We make the vending machine to be so ubiquitous that it becomes a no-brainer, and so that it’s not expensive or arduous to maintain,” says Bashkin. “For most machines that industrial distributors acquire on behalf of their customers, that cost is then passed onto the end users—in some cases without them even realizing it, so the less they have to bundle into the product price, the better it is for customers who consume that product.”

MRO management improves when data, metrics and analytics enter the picture.

Keeping them honest

Like many other corners of the business world, MRO management improves when data, metrics and analytics enter the picture. Put a vending machine and its advanced software platform on the manufacturing floor, for example, and it won’t take long for the benefits to start adding up. “The software that resides in these machines is quite powerful,” says DeBerry, “and enables functions like the kitting of parts for certain applications.”

Let’s say a machine operator needs a certain package of parts to run a new job. After swiping his card through the vending machine, he keys in a job number, and then stands by for a few seconds as five different drawers light up. He grabs the five parts out of the drawers, goes back to his workstation, and starts on the job.

The software also generates reports that can be automatically emailed to (or retrieved on demand by) the appropriate supervisor or manager. If a certain MRO product hits a minimum or maximum level, for example, the supervisor can address the issue without having to physically see the inventory. Finally, the vending machines provide a secure inventory environment for the goods, which can’t be simply “picked off” a shelf. “Because you can’t force the drawers open,” says DeBerry, “access can easily be restricted to specific users.”

Improved accessibility and flexibility

According to Bashkin, nearly every MRO buyer is looking for reports that answer questions like: What are we using? Who’s using what? How much are they using? And, when are they putting it back (i.e., in the case of reusable items like tools)? The vending machines provide answers to these and other questions in a report format, thus allowing buyers to make good purchasing decisions.

An MRO manager at an automotive plant, for instance, may want to see one report by floor and another by department—with the associated employee and product IDs—to determine usage and purchase requirements. Another manager may want the same data organized according to work order or the day of the week. These and other reports are all obtainable on-demand from the machines,” says Bashkin, “with just a couple of clicks.”

Much like their consumer-focused cousins—which dispense food, beverages and other items in various settings—industrial vending machines give users free access to the items they want and need, and all without the need for a middleman. This, in turn, helps to improve operational efficiencies while allowing employees to focus on more important tasks. “They provide control, but are also easy and flexible to use,” says DeBerry, “while only giving access to the people who need it.”

Companies mentioned in this article

View MRO Products and Accessories

MRO Products & Services

MRO Products & Services

MRO products and services now offered.

Gearwrench mobile workstation

Gearwrench mobile workstation

Workstation created for plant maintenance.

Specialist Cleaner & Degreaser

Specialist Cleaner & Degreaser

Biodegradable degreaser, cleaner.

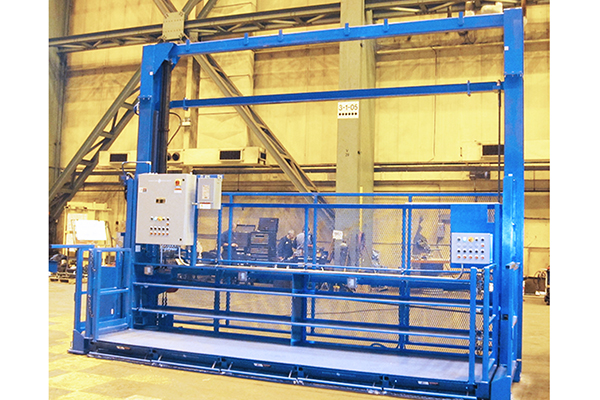

Custom Personnel Lifts & Work Access Platforms

Custom Personnel Lifts & Work Access Platforms

Maintain large machinery with personnel lift.

Conveyor Replacement Parts

Conveyor Replacement Parts

Conveyor replacement parts minimize downtime.

CentraPower hydraulic system

CentraPower hydraulic system

Combine dock levelers with single station.