Most Companies Fail with ERP for Supply Chain Orchestration

Study: Companies relying on ERP for supply chain visibility fall short of goals for the extended supply chain - misalignment between IT and business executives results in 50% gap in inter-enterprise visibility capabilities.

The availability of a new report conducted by Supply Chain Insights indicating that despite the explosion of global outsourcing and increased efforts to automate the extended supply chain, the focus of most companies remains on automation within the enterprise, leaving interactions between business partners to spreadsheets and EDI.

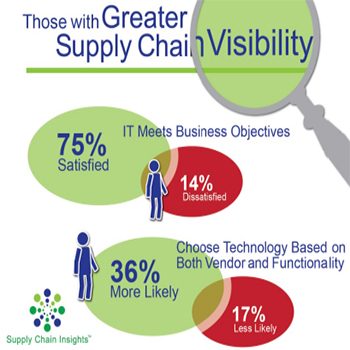

Misalignment between IT and supply chain leaders directly hinders global initiatives centered on supply chain visibility and agility.

“Supply chain processes are more dependent on trading partners and interactions across the extended supply chain, but IT capabilities are largely based on electronic data interchange and spreadsheets, which is inadequate,” said Lora Cecere, CEO of Supply Chain Insights.

“For over fifty percent of companies IT spending is primarily focused on Enterprise Resource Planning (ERP) which automates processes within the single company, not the end to end network. This is a conundrum for the supply chain leader.”

Companies Relying on ERP for Supply Chain Visibility Fall Short of Goals for the Extended Supply Chain

Key Findings:

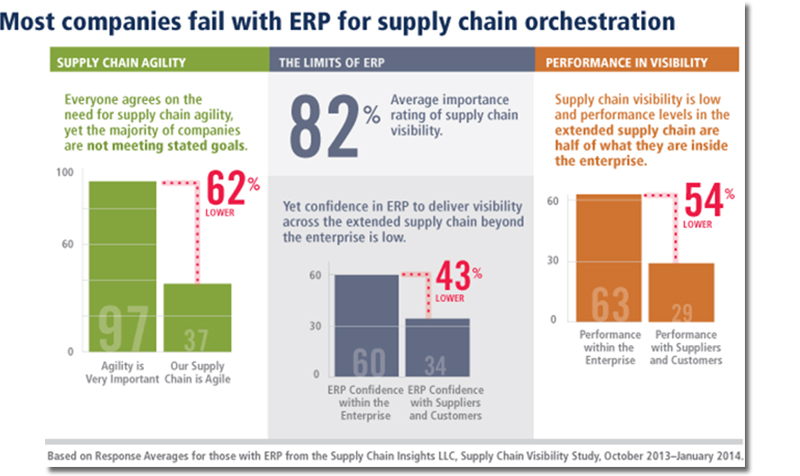

- 97% of companies agree on the need for supply chain agility but only 37% of companies are meeting their stated goals. This 60 point difference constitutes a 62% gap.

- The average Importance Rating for supply chain visibility across external partners is 82%. But confidence in ERP to deliver visibility across the extended supply chain beyond the enterprise is low. 60% of those surveyed have confidence in ERP to deliver visibility within the enterprise. But only 34% have confidence in ERP to provide visibility with suppliers and customers. This 26 point difference equates to a 43% drop in confidence.

- Supply chain visibility is low and performance levels in the extended supply chain are half of what they are inside the enterprise. There is a 54% gap between visibility performance within the enterprise versus visibility with suppliers and customers.

This report is based on results of a quantitative study. Fifty-nine percent of the respondents are heads of supply chain efforts for global manufacturers.

“Companies claim to be building end-to-end supply chain visibility systems, but as this study indicates, these claims are not accurate,” said Greg Johnsen, Founder and Chief Marketing Officer of GT Nexus. “Business leaders recognize the value of supply chain visibility but the approach being deployed on the IT side is proving to be outdated.

Related: Proper Inventory Management Through Supply Chain Visibility

The gaps in current supply chain capabilities are large. ERP is effective within the four walls of the business and EDI is effective in moving transactional data. But business networks require new solutions for supply chain visibility and agility. Current IT architectures are not meeting this need.”

The study finds gaps in supply chain visibility are large and supply chain leaders’ confidence in existing Enterprise Resource Planning (ERP) systems to close the gap is low. Meanwhile, the average company has seven ERP instances and 49% of respondents report ERP spending consumes a major portion of their IT budgets.

Cecere added, “To close the gap and improve supply chain visibility, there is not a clear path forward. There is friction between line-of-business leaders and IT. Line-of-business leaders are struggling to find funds for non-ERP supply chain visibility initiatives and IT is not in general agreement that the visibility gap cannot be closed through ERP.”

About the Author

Lora Cecere is the Founder and CEO of Supply Chain Insights , the research firm that’s paving new directions in building thought-leading supply chain research. She is also the author of the enterprise software blog Supply Chain Shaman. The blog focuses on the use of enterprise applications to drive supply chain excellence. Her book, Bricks Matter, published in December of 2012.

Article Topics

GT Nexus News & Resources

The Current and Future State of Digital Supply Chain Transformation Infor Coleman AI Platform to ‘Rethink Supply Chain’ and Maximize Human Work Potential End-to-End Visibility: Handling the Demands of Retail Mastering Supply Chain Finance ERP Suppliers’ Changing Role New Logistics TMS Platform Sets Sights on SAP Amazon Selects Infor for Global Logistics Business More GT NexusLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain