A Look at Vendor Managed Inventory Strategies

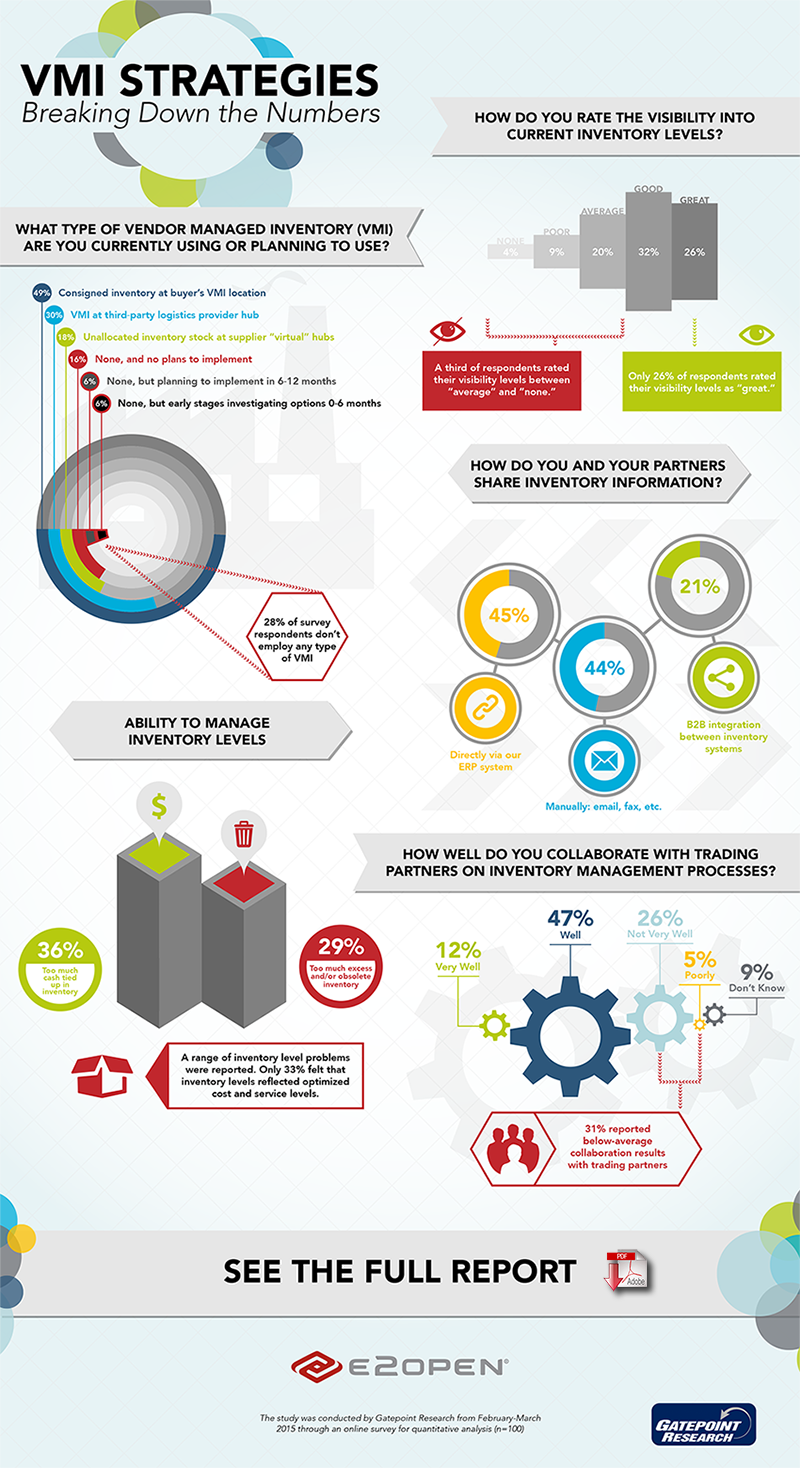

Vendor Managed Inventory is a brilliant concept in theory, but in reality, few companies are able to achieve its full potential and create that mutually beneficial relationship between customer and supplier.

When suppliers don’t have visibility into your demand forecast, they manage inventory based on agreed upon safety stock and min-max inventory levels, historic purchase patterns, or simply fulfill a PO once it arrives.

In order to accommodate changing demand patterns and meet service levels, suppliers often increase their own finished goods inventory, which means additional finished goods locations and higher overall inventory costs. Ultimately, these costs are passed on to you in the form of higher prices.

Forecast collaboration allows you to improve the efficiency of your current inventory management program, and also puts you in a good position to set up a more sophisticated VMI program. Here’s how:

By providing your suppliers with real-time visibility into your demand forecast, they are able to more effectively schedule operations and plan capacity usage in order to meet your current requirements.

This means: lower costs across the board - with fewer manufacturing changeovers; an increased percentage of low-cost, full truckload shipments; and the ability to replenish based on minimum economic order quantity.

By gaining visibility into your upcoming sales promotions, suppliers are able to make and ship additional quantities during predefined promotional periods - minimizing last-minute rush shipments and reducing the risk of stock outs.

Visibility into promotions also allows suppliers to register (promotion-based) increases in demand as “one-off events,” preventing distortion in average demand calculations, which often leads to unwarranted increases in safety stock.

Gaining visibility into your demand forecast also allows your suppliers to coordinate replenishment orders and deliveries across multiple customers in order to improve service. For example, a noncritical part delivery can be diverted for a day or two to another customer who needs a critical delivery without putting you at risk.

Similarly, a smaller-than-usual replenishment to you may enable a larger-than-usual shipment to another customer in dire need, without disrupting your service levels.

What goes around comes around. By being able to balance the needs of various customers, suppliers are able to improve the network’s overall performance without jeopardizing the service levels of any particular OEM or customer.

Without demand forecast visibility, suppliers don’t have the timely, accurate information necessary to prioritize customer shipments effectively.

Article Topics

E2open News & Resources

E2open President and CEO Farlekas Provides Logistics Trends and Themes Overview E2open Transportation Management Solution to Simplify Your Logistics Supply Chain Disruptions and the Next Normal for Logistics in 2023 Outsourced Quality and Sustainable Manufacturing in a World of Disruption Mitigating Supply Chain Disruption in the Wake of Severe Weather and Disasters Uber Freight & E2open to Provide Real-time Transportation Rate and Capacity Options Tracking and Reducing Transportation Emissions More E2openLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain