Learning the Language of Market Driven Demand

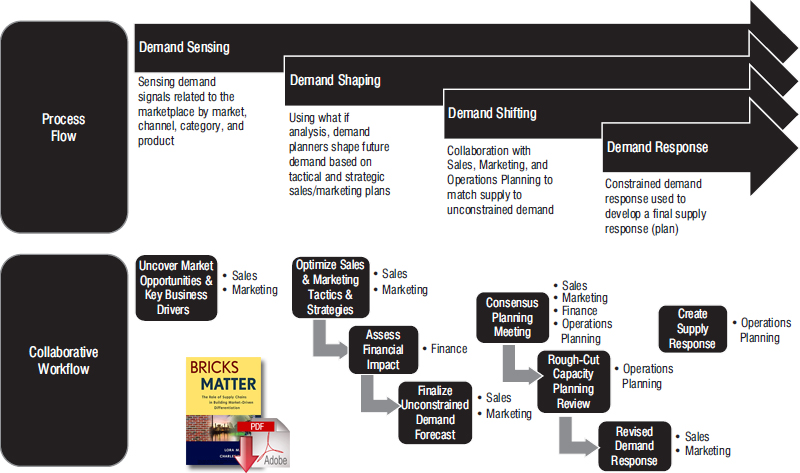

To become market driven, companies need to identify the right market signals, build sensing capabilities, define demand-shaping processes, and effectively translate the demand signal to create a more effective response.

New shoes feel awkward. Blisters appear. Feet hurt. The shoes are worn for short periods. Often we shelve them to allow our feet to recover. However, over time, they slowly feel comfortable. They become a part of our wardrobe.

Learning to speak a new language is similar. Conversations are strained. Mistakes are made. Pauses are awkward. Confusion reigns. Communication is stilted. It takes time. Slowly the words take definition in everyday speech.

Nine out of ten supply chains are stuck. Growth has slowed. Complexity has increased. Companies are stuck at the intersection of inventory turns and operating margin. They are unable to drive improvements in both. The secret to unsticking the supply chain is to redesign processes to be outside-in. The supply chain processes need to be designed from the market back.

This a step change, not an evolution. Why? Most companies have designed supply-centric processes from the inside-out. The first step to making the shift is learning a new language.

Step Up and Learn the Language of Demand

In companies, there is no standard model for demand processes. It is evolving. New forms of analytics make new capabilities possible. In the traditional organization, some demand processes are sales-driven. Others are marketing-driven. However, sales-driven and marketing-driven processes are quite different from market-driven processes.

Unfortunately, companies have invested money in traditional forecasting processes believing that if they make the forecast better that corporate performance will improve. Improving forecasting is not sufficient. It is about much more than conventional forecasting. While we need forecasting and we need to improve the processes, we also need to teach teams how to use new forms of demand data and adopt demand processes.

Why is this important? Supply chain leaders are fluent in the language of supply. They don’t know the language of demand. To become demand driven (or market driven), they need to learn how to speak a new language. In this process, they slowly learn that the customer order is a poor representation of demand.

Market-Driven Demand Management Process

Speaking the Language of Demand: New Terms to Know

The concepts of demand driven are now vogue. Many supply chain consultants will quickly rattle off case studies and proof points, but the smart supply chain leader will ground the discussion with clear definitions. Let’s start with these:

- Demand Sensing: The reduction of time to sense purchase and channel takeaway. Demand sensing is a process, automated by technology, that reduces demand latency.

- Demand Latency: The latency of demand signal due to demand translation of a customer purchase through the supply chain to an order for a trading partner. The time is different in each supply chain based on product sales velocity and the technologies used. For example, in a hospital, it is the translation of usage in a procedure to hospital order to a distributor and the translation of that usage to an order for a manufacturer. This time lapse varies by product and by channel. For the purchase of Tide at Walmart to translate to an order at P&G, the time is 5-7 days. For the translation of a purchase of Aleve at a retail outlet store to Bayer, the manufacturer is 60 days. As the long tail (small orders shipped with low-frequency) of the supply chain grows, demand latency increases and there is a greater need for demand sensing technologies.

- Independent Demand. The purchase of a product by a customer in the channel.

- Dependent Demand. The translation of this demand signal from a channel demand signal to a manufacturer or a distributor through a bill of material or a transportation or manufacturing routing.

- Demand Translation. The translation of demand by role within the organization. Each role–customer service, sales, procurement, manufacturing have a different need/definition for the demand signal.

- Demand Shaping. The use of demand tactics price, sales incentives, marketing programs, new product launch, promotions, and assortment to increase baseline forecasting.

- Demand Shifting. The shifting of demand from one period to another (examples include pre-shipments at the end of the quarter, stuffing the channel to get rid of stock, or shipping early) increases supply chain costs and distorts the demand signal. Try to minimize demand shifting and maximize the value of demand shaping. Get clear on the difference.

- Forecastability. The mathematical determination of ease of forecasting (the determination of the probability of demand). Many technologies include this in the base software package.

- Forecast Value-Add (FVA): A methodology for continuous improvement of the demand plan where steps of the process are evaluated and the question is asked, “Did this change improve the forecast (bias and error) as compared to the naive forecast?” (For more on this topic check out the book, The Business Forecasting Deal.)

- Naive Forecast. The historic forecast using prior month shipments.

- Downstream Data: Use of channel data (Point of Sale (POS) and Warehouse Withdrawal) to sense channel demand.

- Demand Synchronization. The demand signal must be connected from node to node in the supply chain and then synchronized and mapped. The most frequently mapped data elements are product hierarchies, time/calendars, and locations. In this mapping, the data granularity and frequency must be harmonized.

- Demand Visibility. The translation of demand by role across the organization and across tiers and nodes of the supply chain.

- Demand Consumption. The translation of the demand signal across planning horizons. In early planning products this was accomplished through rules-based consumption. New and more advanced technologies are using optimization and cognitive learning techniques to consume the forecast across planning horizons.

- Integration. Close coupling of the data elements to use the data into software. Integration without synchronization and harmonization does little for the demand signal.

- Harmonization. Data harmonization enables data of differing granularity and data structures to be harmonized into a common database.

The New World of Demand Management: Demand Sensing, Shaping, and Translation

You can ’t wish demand to happen. There are no magic wands or easy buttons. —Charles Chase

The global marketplace is volatile, fragmented, and dynamic. Supply processes are more mature than demand. There is a larger gap to fill in the redefinition of demand processes to be market driven than in any other area of supply chain management.

To become market driven, companies need to identify the right market signals, build sensing capabilities, define demand-shaping processes, and effectively translate the demand signal to create a more effective response. This approach makes the 30 years of technology and process thinking by the first- and second-generation supply chain global pioneers obsolete.

Demand management processes are challenging. They are more difficult to get right than supply. Talent is scarce and the processes are evolving. Organizationally, the work on demand processes is fraught with political issues. (Demand processes are more politically charged than supply processes.)

As a result, many companies often want to throw in the towel. They want to forget demand and only focus on the redesign of supply processes to become more reliable, resilient, and agile. The list of possible projects is long and often includes lean manufacturing, cycletime reduction, order management, or the redefinition of distribution center flows.

However, focusing only on supply has limited results. Supplycentric approaches can only impact business complexity. It cannot improve the potential of the supply chain as a complex system. Working supply processes in isolation to demand will drive up costs, increase working capital, and reduce asset utilization. The secret to building supply chain excellence is to build the right stuff in the demand management processes. Improvements in demand management will give the supply chain the right foundation to make effective trade-offs against the supply chain effective frontier (Figure 1.1 ).

Download all of Bricks Matter Chapter 3 - The New World of Demand Management: Demand Sensing, Shaping, and Translation. Cecere, Lora M., and Charles W. Chase.

Purchase online - Bricks Matter: The Role of Supply Chains in Building Market-Driven Differentiation.

Download the Research Paper: Building Market-Driven Value Networks