Lean Manufacturing Driven by Technology Investment

Lean Manufacturing, allows a manufacturer can accurately and effectively calculate the optimal level of inventory needed to fulfill demand requirements through the duration of replenishment lead time.

Lean Manufacturing relies heavily on trusted relationships with suppliers and pre-negotiated terms of engagement.

Through the use of supplier quality certifications and blanket (long-term) purchase orders, a manufacturer can accurately and effectively calculate the optimal level of inventory needed to fulfill demand requirements through the duration of replenishment lead time.

Ensuring supplier performance

When a relationship is setup with a supplier, a service level agreement is defined. Items such as negotiated lead times, packaged quantities, order receipt confirmations, and advanced shipment notices must all be specifically spelled out.

An eKanban Pull-based inventory replenishment system monitors that each aspect of the service level agreement is being met by the supplier in real-time. If they are not, a series of alerts and notifications are issued to all interested and affected parties. This gives everyone a chance to quickly adjust their behavior to bring performance back in line.

eKanban software also makes all of this real-time information available for historical analysis and to identify trends in performance. Late shipments, short shipments, and other supply chain performance concerns are all captured and presented in terms of percentage of conformance to the service level agreement. These reports give everyone in the supply chain information about how to focus their continuous improvement energies.

Eliminating inventory waste

eKanban is heavily based on Lean and Six Sigma principles and tools, and adds focus to these efforts by eliminating inventory waste through real-time demand signaling and just-in-time replenishment.

eKanban replenishment is based on the notion that if you take one, you make one. As such, you are reducing on hand inventory and not building assemblies or products without actual demand.

You dramatically reduce the amount of inventory that becomes old or obsolete, free warehouse space and you build flexibility – and potential capacity – into your production process. An eKanban system exposes this flexibility so that manufacturers and suppliers can rapidly evaluate the true capability of the system to respond to a specific change in demand.

Manufacturing operations utilizing Lean are increasingly implementing Pull systems with more suppliers. And eKanban systems are taking hold as a relatively easy, and non-disruptive way to introduce Lean thinking into the organization – and bank on a quick return.

Just in “right-sizing” inventory levels alone, some manufacturers have saved millions and added tens of millions back to cash flow that can be put to use in more productive ways than filling a warehouse. Additional savings are being realized in improved supplier relationships, lead times and inventory turns – and a dramatic reduction in administrative paperwork.

If you have an experience using a manual or eKanban system, please add a comment. I’d like to hear it!

Related White Papers & Guides

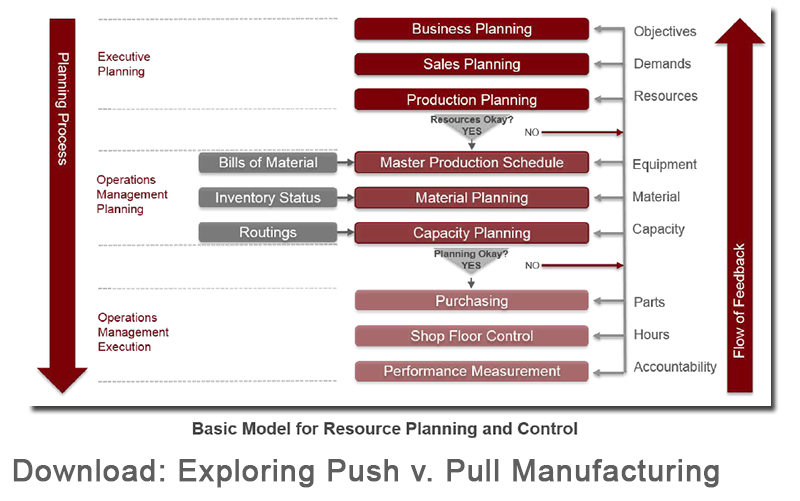

Gaining Control: Exploring Push v. Pull Manufacturing

If you’re considering a shift from a traditional, push-based MRP manufacturing system to a more progressive pull-based system, this white paper is a must read. Download Now!

Gaining Confidence: Syncing Supplier Delivery to Customer Demand

Demand-driven and lean production allows manufacturers to be more responsive to consumer needs while increasing their own profitability, it also reduces the reliance on forecasts by linking demand signals and providing real-time data directly to suppliers. Download Now!

Why Become More Demand-Driven?

In this paper, we will examine the nuts and bolts of “common” manufacturing environments and look at how software solutions help harmonize these processes using improved data, visibility and demand-driven practices. Download Now!

Article Topics

Synchrono News & Resources

Strategies for Managing Manufacturing Bottlenecks and Constraints Eliminate Production Bottlenecks; Manage Manufacturing Constraints Demand-Driven Manufacturing Can Help You Cost-Justify Your Next IIoT Project Technology will Connect Your Enterprise and Create the Demand-Driven Factory of the Future - Today Time for Manufacturers to Cut Ties with MRP and Spreadsheets How SyncKanban eKanban Software Addresses Lean’s 8 Forms of Manufacturing Waste The 8 Forms of Waste in Lean Manufacturing More SynchronoLatest in Supply Chain

U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Frictionless Videocast: The Importance of Water at the U.S./Mexico Border with Commissioner Maria-Elena Giner, International Boundary and Water Commission Why are Diesel Prices Climbing Back Over $4 a Gallon? Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring More Supply Chain