Know Your Different Types of Corrugated Cardboard

How well do you know the different types of corrugated cardboard? If your answer was “I didn’t even know there was more than one type,” you probably don’t work in the packaging industry.

What is corrugated cardboard in the first place?

Well, if we want to get really technical here, the correct term is corrugated fiberboard. Cardboard is a generic term that includes all types of heavy-duty paper that can include card stock, paperboard, and corrugated fiberboard. However, when the average person thinks about cardboard, the first image that pops into their head is likely corrugated fiberboard.

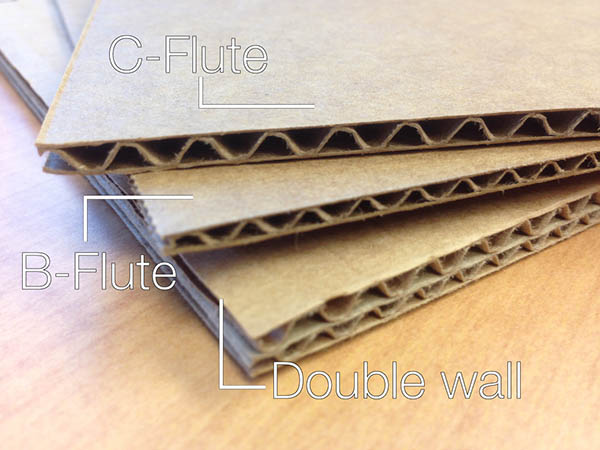

There are several sizes and styles that corrugated cardboard comes in. Here’s a quick look at a few of them:

1. Single Face Board—Doesn’t have the durability that other types of corrugated have, but is very cheap to produce and can provide an extra layer of protection to already packaged products.

2. Single Wall Board—The most common style corrugated cardboard is manufactured in. Some of the more common flutes of single wall boards are listed below.

- C-Flute is by far the most common corrugated flute because of its versatility. It’s an acceptable surface to print on and is strong enough for most shipping situations. It’s not great at folding in the direction of the fluting, but is still adequate for most users.

C-Flute is 3-16ths of an inch thick.

- B-Flute is a little bit smaller at 1/8th of an inch in thickness, and it is used for smaller products and boxes. It’s better for folding into intricate shapes and for printing, so this is the flute usually seen for Point-Of-Purchase (P.O.P.) displays or for cardboard cutouts.

- E-Flute is very thin at 3/32nds of an inch. It’s very easy to fold and is excellent for printing. It’s used as the primary packaging for many smaller boxes, such as a pizza box.

- F-Flute is micro thin at only 1/16th of an inch. It was designed to send less waste to landfills and is used for specialty packaging and shoeboxes.

3. Double Wall Board—Much more resistant to breaking when stacked. This type of corrugated is commonly used for larger industrial containers.

4. Triple Wall Board—Strong enough to be a substitute for wooden crates. It has traditionally been used for shipping chemical containers.

This has been an introductory lesson on the makeup of corrugated fiberboard and a few of the different kinds of corrugated. We consider ourselves something of an expert on packaging and packaging materials.

If you would like to learn more about Packsize and On Demand Packaging®, please fill in the Request for Information form on the right hand side.

Article Topics

Packsize News & Resources

Enhancing Brand Value With Optimized eCommerce Packaging Packsize Partners with Paccurate for Sustainability and Launches their “Easy Close” Solution Packsize advances sustainability efforts with new Paccurate partnership Cardinal Health at-Home Solutions automates from shelf to patient Inside Cardinal Health at-Home: Getting the right products out the door at the right time The Power of the Perfect Box Design How Right-Sized Packaging Automation Can Reduce your Carbon Footprint More PacksizeLatest in Warehouse|DC

U.S. Manufacturing is Growing but Employment Not Keeping Pace Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds More Warehouse|DC