Inside the Biggest Factory in the World

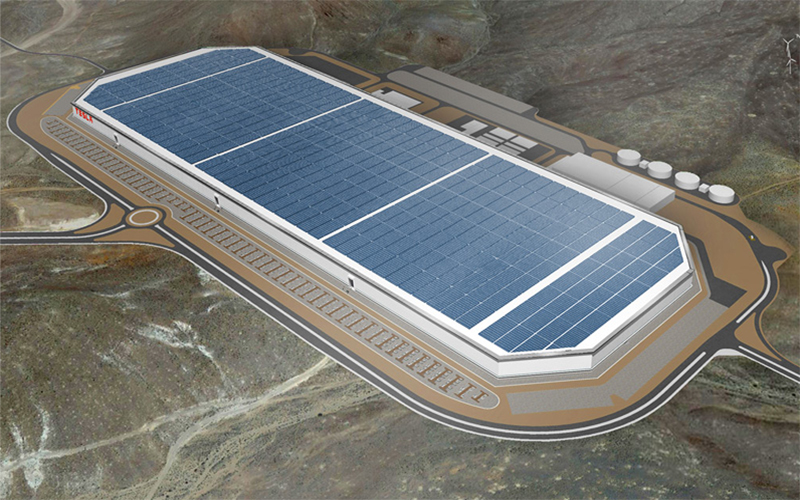

When Tesla's Gigafactory is complete it will be the largest building in the world by footprint and, if all goes according to plan, will eventually churn out enough batteries to supply 150 gigawatt hours of batteries per year.

When you find yourself in the middle of the Nevada desert, on a 100-degree day, you wonder: who in the world would build something here?

Elon Musk, of course.

And so I’m here in the city of Sparks, outside of Reno, because of Musk’s dream - his “Master Plan” for Tesla, to be specific.

He’s staked his entire company (and much of his net worth) on a single, enormous building here: the Gigafactory.

Tesla’s Gigafactory is perhaps the best example of the literal scale of Elon Musk’s ambitions.

When the factory is complete, it will be the largest building in the world by footprint and, if all goes according to plan, will eventually churn out enough batteries to supply 150 gigawatt hours of batteries per year.

That’s enough for 1.5 million Model 3s. Tesla hopes to build 35GWh of batteries per year by 2018, equivalent to 500,000 Model 3s.

Pull up “large” in your thesaurus and you can easily apply any synonym to the plant: great, huge, sizable, substantial, immense, enormous, colossal, massive, mammoth, vast, prodigious, tremendous, ginormous - all of them apply. And maybe that doesn’t even capture it.

Tesla Gigafactory

Tesla’s mission is to accelerate the world’s transition to sustainable energy. To achieve that goal, we must produce electric vehicles in sufficient volume to force change in the automobile industry. With a planned production rate of 500,000 cars per year in the latter half of this decade, Tesla alone will require today’s entire worldwide production of lithium ion batteries. The Tesla Gigafactory was born of necessity and will supply enough batteries to support our projected vehicle demand.

Tesla broke ground on the Gigafactory in June 2014 outside Sparks, Nevada, and we expect to begin cell production in 2017. By 2020, the Gigafactory will reach full capacity and produce more lithium ion batteries annually than were produced worldwide in 2013.

In cooperation with Panasonic and other strategic partners, the Gigafactory will produce batteries for significantly less cost using economies of scale, innovative manufacturing, reduction of waste, and the simple optimization of locating most manufacturing process under one roof. We expect to drive down the per kilowatt hour (kWh) cost of our battery pack by more than 30 percent. The Gigafactory will also be powered by renewable energy sources, with the goal of achieving net zero energy.

The name Gigafactory comes from the factory’s planned annual battery production capacity of 35 gigawatt-hours (GWh). “Giga” is a unit of measurement that represents “billions”. One GWh is the equivalent of generating (or consuming) one billion watts for one hour - one million times that of one kWh.

View 9 Slides: Putting the New Tesla Gigafactory in Perspective

The building, which Musk finds “quite romantic,” is aligned north to south. It will be large enough to cover 107 NFL football fields with two to four floors of factory floor and workspace layered on top. There are 10,000 wild horses in the area, with some taking advantage of Tesla’s construction efforts to drink from the water storage pools used during the building process.

“It’s great,” said Musk in a press conference with reporters at the Gigafactory last Friday. “It’s like the Wild West.”

But, according to Tesla, it’s so much more than a battery factory. Forget the Model 3: the success of the Gigafactory is the most critical part of Tesla’s future and the execution of Musk’s overriding quest to save the world from the effects of climate change. Without the Gigafactory, there is no Model 3 because there will be no batteries.

“We consider [the factory] to be a product. The factory itself is the machine that builds the machine,” said Musk. “It actually deserves more attention from creative problem solving engineers than the product that it makes.”

Musk argues that applying engineering effort to refining the production process is a better use of man-hours than trying to wring the last little bits of efficiency out of his cars. An engineer working on improving the factory line is five to 10 times more productive than that same effort put on the product that’s actually being built.

“It takes a massive amount of effort to improve the inverter efficiency by a few tenths of a percentage point,” said Musk. “You have to really wrack your brain and try super hard and take a lot of risks to improve efficiency by a few tenths of a percentage point.” But apply that same engineering effort to the process of building the inverter and it can deliver 10 times the efficiency improvement. Musk cited one example where his engineers were able to reduce a production station’s time from 200 seconds to a single second.

I’ll admit that I thought the idea of the Gigafactory was absurd when it was first proposed three years ago. I wasn’t the only one. Panasonic is investing huge sums of money to build battery production lines right inside the Gigafactory - it’s a sort of tenant/landlord situation where Panasonic owns its production lines and delivers battery cells right to the front end of Tesla’s production line.

Standing inside the building, staring agape at the sheer audacity of the project, it’s easy to say, “Oh, yeah, this all makes sense.” But Panasonic executive Yoshi Yamada said he wasn’t always on board.

View 9 Slides: Putting the New Tesla Gigafactory in Perspective

Three years ago, when the Gigafactory was first proposed, “I thought it was crazy,” said Yamada. “At that time, production capacity of this Gigafactory would exceed total production of the industry. Not Panasonic. Not Japanese companies. All Japanese, Korean, and Chinese companies combined. I thought it was a crazy idea.

“But I was crazy. And I was wrong. After seeing extraordinary success of the announcing of Model 3, there is a strong demand for this battery. So, three years ago I thought this was a crazy idea. But I was crazy at the time.”

This is as significant a project for Panasonic as it is for Tesla. The vast majority of these types of batteries are built in Asia, and this plant is a first for Panasonic. Given Donald Trump’s relentless focus on international trade deficits and the decline of US manufacturing, the rollout of this factory is perhaps perfectly timed.

“We really wanted to contribute to the sustainable world, that’s number one,” said Yamada. “The second thing is that I think we really change business relationship between two companies: from the buyer-supplier relationship to one team.”

Walking around the factory, there are massive, two-story-high battery production lines owned by Panasonic. There are taped lines on the floor showing where the Tesla production floor ends and Panasonic’s begins. Raw materials will go in one end, run through the line, and then spit out a battery cell, ready to be installed in Tesla battery packs on the next line.

“Gigafactory is the most exciting factory in the world,” said Musk. “If you want to work on a factory, you want to work on this factory. What would be option two?”

To hear Musk tell it, the Gigafactory is as important to electric cars as Henry Ford’s production line was to the automobile a century ago. It’s the electric car version of Dell’s revolutionary just-in-time PC factory: put supplier production and final assembly under one roof, saving on transportation costs and allowing for reduced inventory.

Raw materials go in the south end and assembled battery packs come out the north, all shepherded by close to 10,000 Tesla employees and a litany of Fanuc autonomous robots. All the steel is fabricated in the US, and the company says none of the raw materials for the steel came from China.

Tesla is acting as its own general contractor, preferring to learn and improve processes itself rather than paying some other company to do it. That’s in anticipation for future Gigafactories, which will be built around the world as demand grows. Facilities in Europe, China, and India are all on the drawing board according to Musk, with the institutional knowledge gained from this building used to improve the next version. Future Gigafactories will likely include vehicle assembly lines too, making the whole process even more efficient.

But why here, in an empty expanse of Nevada, for the first facility? The state has been generous with tax breaks in recent years, for one. Tesla is working with the University of Nevada to create battery-related engineering classes to create a pipeline of talent, while the state is building a new road to connect the industrial park where the Gigafactory is located to US 50 to the South. The theory goes that it’ll benefit both Tesla and its neighbor companies in this business-friendly part of the country.

View 9 Slides: Putting the New Tesla Gigafactory in Perspective

The end goal for the Gigafactory is to drive down the cost-per-kilowatt hour of batteries, making Tesla’s cars and energy storage products (giant batteries used for power reserves in residences, commercial and industrial buildings, and even by energy utilities) much more affordable. Without it, the growth that Tesla plans simply wouldn’t be possible.

At the moment, Tesla’s electric cars get all the attention, but Musk says its storage products could end up just as big. Stationary storage is “something I think will probably be as big as the car business long term,” Musk said. “And will actually have a growth rate probably several times that of what the car business is per year. The growth in stationary storage is really under appreciated. That’s a super-exponential growth rate.” Tesla’s Powerwall and Powerpack are being assembled at the Gigafactory today.

To make an analogy to SpaceX, another Musk venture, Tesla has spent the last decade getting itself to the launchpad. The Gigafactory is the final piece of the Tesla rocket, the last check before takeoff. Now we get to see if the launch is nominal or blows up before it can get off the ground.

But unlike at SpaceX, where a single exploded rocket is a mere setback, the failure of the Gigafactory would be a $5 billion mistake. It would have real potential to kill off Tesla. The entire company - indeed, Musk’s entire electrified dream - is at stake.

It’s hard to judge Musk’s even-more-ambitious plan to put a man on Mars. It’s so far away, literally and figuratively, that it’s easy to laugh off any predictions of success or failure. But the Gigafactory is here today. I stood inside it. Colonizing another planet is certainly cooler than a giant building full of batteries, but pulling this off would be a moonshot in its own right.

Source: The Verge

Article Topics

Omron Adept Technologies News & Resources

Omron helps University of Houston Engineering students gain real-world skills Omron Automation and Voelker Controls Company announce new partnership Omron and Taiwanese collaborative robot company Techman Robot form strategic alliance Labeling software powers supply chain improvements for hazardous goods handling Ford Challenge to Create ‘Last Mile’ Mobility Solutions Solving the Challenges of Changing Product Requirements with Flexible Manufacturing Achieve Packaging Sustainability with Flexible Automation More Omron Adept TechnologiesLatest in Technology

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology