Incredibly Successful Supply Chain Management: How Does Walmart Do It?

When you drop by Walmart, you are witnessing one of history’s greatest logistical and operational triumphs.

According to a recent article, this retail giant stocks products made in more than 70 countries and at any given time, operates more than 11,000 stores in 27 countries around the world, and manages an average of $32 billion in inventory.

With these kinds of numbers, having an effective and efficient supply chain management strategy and system is imperative. The entire organisation is committed to a business model of driving costs out of supply chains to enable consumers to save money and live better.

Over the past ten years, Walmart has become the world’s largest and arguably most powerful retailer with the highest sales per square foot, inventory turnover, and operating profit of any discount retailer. In its transition from regional retailer to global powerhouse, the organisation has become synonymous with the concept of successful supply chain management.

“I don’t believe there is a university in the world that doesn’t talk about Walmart and the supply chain,” said James Crowell, director of the Supply Chain Management Research Center at the Walton College of Business. “They are just so well respected because they do it so well.”

Walmart began with the goal to provide customers with the goods they wanted whenever and wherever they wanted them. The company then focused on developing cost structures that allowed it to offer low everyday pricing. Walmart then concentrated on developing a more highly structured and advanced supply chain management strategy to exploit and enhance this competitive advantage and assume market leadership position.

Inventory Management 101

What exactly is inventory management, and why is it so important to your business?

While many definitions exist, the core concept revolves around keeping track of your stock on hand – and utilizing this intelligence to optimize your inventory to best satisfy market and customer demand, without exposing your company to unnecessary costs and risks.

Download the White Paper: Inventory Management 101 including Inventory & Supply Chain Management Lessons From Retail Giants

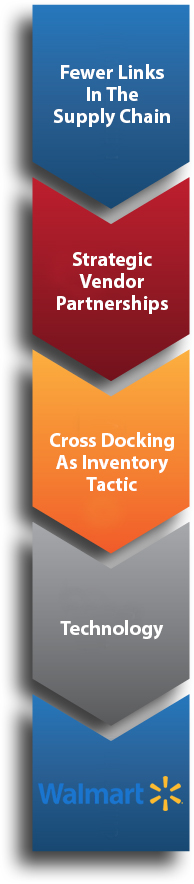

Fewer Links In The Supply Chain

Even in its early years, Walmart’s supply chain management contributed to its success. Founder Sam Walton, who owned several Ben Franklin franchise stores before opening the first Walmart in Rogers, Ark in 1962, selectively purchased bulk merchandise and transported it directly to his stores.

Related: Walmart Logistics Exec Talks Leadership and 3 Servant Lessons From Sam

Walmart’s supply chain innovation began with the company removing a few of the chain’s links. In the 1980s, Walmart began working directly with manufacturers to cut costs and more efficiently manage the supply chain.

Under a Walmart’s supply chain initiative called Vendor Managed Inventory (VMI), manufacturers became responsible for managing their products in Walmart’s warehouses. As a result, Walmart was able to expect close to 100% order fulfilment on merchandise.

In 1989, Wal-Mart was named Retailer of the Decade, with distribution costs estimated at a mere 1.7% of its cost of sales – far superior to competitors like Kmart (3.5%) and Sears (5%).

The company’s supply chain has only become more effective since then.

Strategic Vendor Partnerships

Walmart embarked on strategic sourcing to find products at the best price from suppliers who are in a position to ensure they can meet demand. The company then establishes strategic partnerships with most of their vendors, offering them the potential for long-term and high volume purchases in exchange for the lowest possible prices.

Furthermore, Walmart streamlined supply chain management by constructing communication and relationship networks with suppliers to improve material flow with lower inventories. The network of global suppliers, warehouses, and retail stores has been described as behaving almost like a single firm.

“Wal-Mart’s whole thing was collaboration,” Crowell said. “That’s a big part of what made them so successful.”

Cross Docking As Inventory Tactic

Cross docking is a logistics practice that is the centrepiece of Walmart’s strategy to replenish inventory efficiently. It means the direct transfer of products from inbound or outbound truck trailers without extra storage, by unloading items from an incoming semi-trailer truck or railroad car and loading these materials directly into outbound trucks, trailers, or rail cars (and vice versa), with no storage in between.

Suppliers have been delivering products to Walmart’s distribution centres where the product is cross docked and then delivered to Walmart stores. Cross docking keeps inventory and transportation costs down, reduces transportation time, and eliminates inefficiencies.

Walmart’s truck fleet of non-unionized drivers continuously deliver goods to distribution centres (located an average 130 miles from the store), where they are stored, repackaged and distributed without sitting in inventory. Goods will cross from one loading dock to another, usually in 24 hours or less, and company trucks that would otherwise return empty “back haul” unsold merchandise.

Using cross docking, products are routed from suppliers to Walmart’s warehouses, where they are then shipped to stores without sitting for long periods of time in inventory. This strategy reduced Walmart’s costs significantly and they passed those savings on to their customers with highly competitive pricing.

Technology

In its relentless pursuit of low consumer prices, Walmart embraced technology to become an innovator in the way stores track inventory and restock their shelves, thus allowing them to cut costs.

Technology plays a key role in Walmart’s supply chain, serving as the foundation of their supply chain. Walmart has the largest information technology infrastructure of any private company in the world. Its state-of-the-art technology and network design allow Walmart to accurately forecast demand, track and predict inventory levels, create highly efficient transportation routes, and manage customer relationships and service response logistics.

For example, Walmart implemented the first company wide use of Universal Product Code bar codes, in which store level information was immediately collected and analysed, and the company then devised Retail Link, a mammoth Bentonville database. Through a global satellite system, Retail Link is connected to analysts who forecast supplier demands to the supplier network, which displays real-time sales data from cash registers and to Walmart’s distribution centers.

Suppliers and manufacturers within the supply chain synchronize their demand projections under a collaborative planning, forecasting and replenishment scheme, and every link in the chain is connected through technology that includes a central database, store-level point-of-sale systems, and a satellite network.

What made Walmart so innovative was that it has been sharing all these information with all their partners and back in the days, a lot of companies weren’t doing that. In fact, they were using third parties where they had to pay for that information.

Walmart’s approach means frequent, informal cooperation among stores, distribution centers and suppliers and less centralized control. Furthermore, the company’s supply chain, by tracking customer purchases and demand, allows consumers to effectively pull merchandise to stores rather than having the company push goods onto shelves.

In recent years, Wal-Mart has used radio frequency identification tags (RFID), which use numerical codes that can be scanned from a distance to track pallets of merchandise moving along the supply chain. As inventory must be handled by both Wal-Mart and its suppliers, Wal-Mart has encouraged its suppliers to use RFID technology as well.

Even more recently, the company has begun using smart tags, read by a handheld scanner, that allow employees to quickly learn which items need to be replaced so that shelves are consistently stocked and inventory is closely watched.

According to researchers at the University of Arkansas, there was a 16% reduction in out-of-stocks since Wal-Mart introduced RFID technology into its supply chain. The researchers also pointed out that the products using an electronic product code were replenished three times as fast as items that only used bar code technology.

In addition, Wal-Mart also networked its suppliers through computers. It entered into collaboration with P&G for maintaining the inventory in its stores and built an automated re-ordering system, which linked all computers between P&G factory through a satellite communication system. P&G then delivered the item either to Wal-Mart distribution centre or directly to the concerned stores.

Walmart’s supply chain management strategy has provided the company with several sustainable competitive advantages, including lower product costs, reduced inventory carrying costs, improved in-store variety and selection, and highly competitive pricing for the consumer. This strategy has helped Walmart become a dominant force in a competitive global market. As technology evolves, Walmart continues to focus on innovative processes and systems to improve its supply chain and achieve greater efficiency.

A close look at Walmart’s supply chain and inventory operations definitely provides valuable learning points that businesses can take and apply to their own operations.

Even Army Col. Vernon L. Beatty, who commanded the Defense Distribution Depot in Kuwait, spent a year with Wal-Mart as part of the military’s Training With Industry program.

“Supply chain management is moving the right items to the right customer at the right time by the most efficient means,” Beatty said in article about his experience. “No one does that better than Walmart.”

Related: Walmart Logistics Exec Talks Leadership and 3 Servant Lessons From Sam

Article Topics

TradeGecko News & Resources

How Does IKEA’s Inventory Management Supply Chain Strategy Really Work? Inventory Management: Everything You Need To Know How Out-of-Stock Inventory is Killing Toys’‘R’‘Us The Long Tail of Inventory and Why It’s Important Incredibly Successful Supply Chain Management: How Does Walmart Do It? Inventory Management 101Latest in Supply Chain

Apple Accused of Multiple Human Rights Violations UPS Struggles in First Quarter With Steep Earnings Decline How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? FedEx Announces Plans to Shut Down Four Facilities U.S. Manufacturing is Growing but Employment Not Keeping Pace More Supply Chain