How the British Supply Chain Industry Needs to Think Outside of the Box

A report by the Confederation of British Industry (CBI) has underlined the importance in strengthening the British supply chain industry, identifying a number of core areas for investment, which could potentially generate £30bn for the British economy.

In order to address the growing skills shortage facing the British supply chain industry, organisations must be prepared to break the mould surrounding the traditional type of employees considered. This is the opinion of global supply chain consultancy Crimson & Co.

To bridge the gap, organisations must begin to think outside the box by employing professionals and graduates with specific skills and capabilities that meet clear business objectives, according to Liz Howat, head of scprime at Crimson & Co.

A report by the Confederation of British Industry (CBI) has underlined the importance in strengthening the British supply chain industry, identifying a number of core areas for investment, which could potentially generate £30bn for the British economy.

A key facet to this is addressing the skills shortage that exists among British supply chain firms, with the report highlighting the need for a greater entrance of STEM (science, technology, engineering and mathematics) graduates inducted into the industry.

These feelings were echoed by the deputy prime minister, who recently announced plans to boost British manufacturing supply chains in 2015 by tackling issues such as innovation and industry skills gaps.

Howat stated that while investment in staff is crucial for the long-term future of the sector in order for it to be effective, firms need to be prepared to re-evaluate the traditional type of candidates it attracts and instead identify potential employees and graduates that have the skills and capabilities that align with the needs of the business.

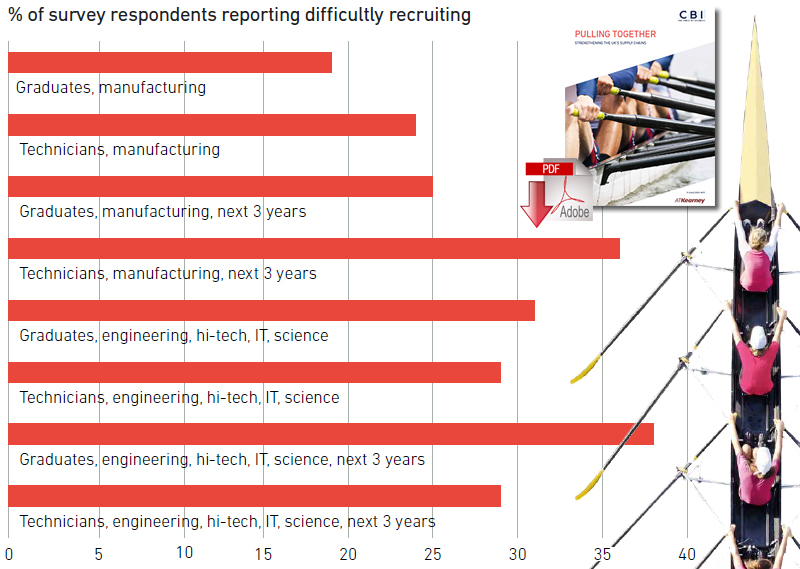

Skills shortages have reached critical levels

Source: CBI education and skills survey data, 2014

“While it’s encouraging to see the industry and the British government acknowledging concerns about skills shortages, it must be prepared to think outside the box in order to address the problems,” said Howat. “Sticking to a set type of employee can potentially have a detrimental impact on the future of your business. To address this, organisations must now begin to think beyond conventional candidate specifications and instead focus on employing people that have developed specific skills, which can ultimately support business objectives.

“Expanding on the standardised job descriptors and broadening the search process opens up organisations to a greater range of candidates that have transferable skills which can be adopted into new roles, and this is the mindset the supply chain industry needs to adopt if it is to address the current industry skills shortage.

“On paper, the theory behind this is obvious. The problem, however, can be when it comes to putting it into practice. The reality is that when it comes to searching outside the box, people naturally gravitate to what they know, and in order to ensure this doesn’t happen, firms can turn to technology.

“Business toolkits are readily available within the marketplace that provide objective assessment around people capabilities in order to ensure that the right people are in the right jobs, and therefore consistently doing the right things. By harnessing the power of technology, it reduces the subjective – organisations can understand what they need and more importantly what they don’t, in order to align with the processes and objectives of the business.”

Source: FoodBev.com

Stronger Supply Chains Could Boost Economy by £30bn - CBI

Potential for 500,000 new jobs across Britain’s regions

Targeted action to revitalise domestic supply chains could inject £30 billion into the economy by 2025, creating more than half a million jobs across the United Kingdom, according to a new CBI report.

Pulling Together recommends ways to kick start the UK’s supply chains, and solutions to reinvigorate Britain’s industrial strategy. Based on new research carried out by A.T. Kearney, the global management consultancy firm, the report reveals underinvestment in research and development (R&D), a growing skills crisis and weakened foundation industries that are key to advanced manufacturing - such as plastics, metals and chemicals.

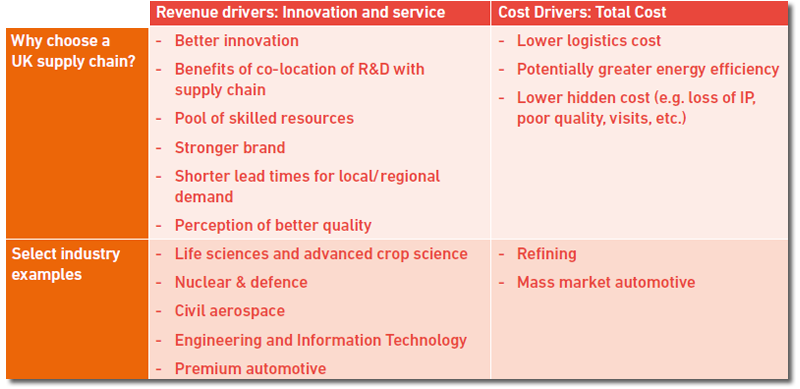

Key supply chain drivers for the UK

Source: CBI/A.T. Kearney analysis

To tackle these issues, the CBI is urging the Government and business to act together to strengthen supply chains, focusing on innovation, better quality products, and excellent customer service. Among the measures the UK’s leading business group is calling for are:

- Setting a long-term target for public and private sector spending on R&D to rise to 3% of GDP

- Widening the R&D tax credit to support the later stages of the commercialisation and manufacture of innovative British products

- Doubling spending on the UK’s innovation agency, Innovate UK, over the course of the next parliament

- Financially incentivising science, technology, engineering and mathematics (STEM) degrees, and ensuring more graduates take up jobs in these sectors

- Creating a national materials strategy, as part of our industrial strategy, to protect and enhance critical supply chain sub-sectors.

Katja Hall, CBI Deputy Director-General, said:

“The molten metals of manufacturing have long coursed through the veins of our economy. Optimism within industry is now rising at a strong rate, and investment intentions are on the up.

“But it’s time for some fresh thinking. We need to see a bold strategy that breathes new life into our supply chains, and makes the UK the destination of choice for manufacturing high value products. This could provide a £30bn boost to the economy, and create half a million extra jobs.

“The scale of the challenge is sizeable - our competitors are powering ahead, with France outstripping our research & development (R&D) investment by 40%. At the same time, only 3% of our graduates end up in engineering or technology jobs.

“We need policies which focus on creating long-term value - from increasing R&D spending to establishing a UK-wide materials strategy - to enable industry to play to its strengths and compete effectively on the world stage.

“This renaissance in British manufacturing will make it a byword for innovation and quality.”

Charles Davis, Strategic Operations Partner at A.T. Kearney, said:

“After years of decline the UK industrial base has stabilised and, with the correct industrial strategy, we can and should look for growth. This will be vital to the long term health of the UK.

“As the challenges of global supply chains become better understood, companies are beginning to look beyond the headline cost to the true value. Winning will be through supply chains that drive revenue, not just striving to be the lowest cost.

This report shows that the most important factor in supply chain location decisions was service/innovation scoring 36%, with total cost next at 30%. While innovation should be the catalyst, at the same time we also need to ensure the skilled resources and correct environment are in place.

“This is a challenge that A.T. Kearney is increasingly seeing beyond the UK – other countries and regions in Western Europe are looking at similar trends as they seek to reinvigorate their industrial bases. As the UK is starting from behind the OECD average for R&D spending, we need to move fast if we are to win.”

Other solutions to strengthen the UK’s supply chains set out in the report include:

Grasping the urgency of the growing skills crisis

As supply chains bear the brunt of skills shortages, the CBI is calling for action to:

- Double the number of STEM graduates, and triple STEM apprentices

- Ramp up female participation in manufacturing, with Davies-style targets

- Reform the immigration system by raising the Tier 2 skilled visa cap

- Better align skills funding with the UK’s industrial strategy.

Moving from being “open for business” to “hungry for business”

To create a more dynamic business environment, and better respond to rapidly emerging opportunities, we must:

- Ensure the tax system encourages long-term investment, particularly in small and medium-sized businesses

- Establish an annual ‘benchmarking’ review to ensure the UK’s energy and logistics costs are globally competitive

- Monitor and tackle ‘red areas’ which hold back businesses’ operations, such as getting electricity set up and registering property.

Understanding the importance of value, not just cost

Public sector procurement decisions cannot be based purely on narrow definitions of value for money, but must take into account their wider impact, on society, communities and the economy.

- The Government should carry out a review in 2017 to gauge how effectively public bodies are considering social value in procurement activities.

Pulling Together: Strengthening the UK’s supply chains was launched at the CBI’s Industrial Strategy Breakfast, attended by Vince Cable, Secretary of State for Business, Innovation and Skills, Matthew Hancock, Minister of State for Business and Enterprise, and Chuka Umunna, Shadow Business Secretary.

Related Article: Supply Chain Talent Is a Growing Gap for Leaders and the Impact Is Enormous