How Pratt & Whitney Is Managing Its Future Growth and Supply Chain Suppliers

While many companies are challenged to grow their revenue in today’s slow economy, Pratt & Whitney faces a different Issue: How to lock up supply as it ramps up to double the output of its new jet engine over the next five years - this is how they did it.

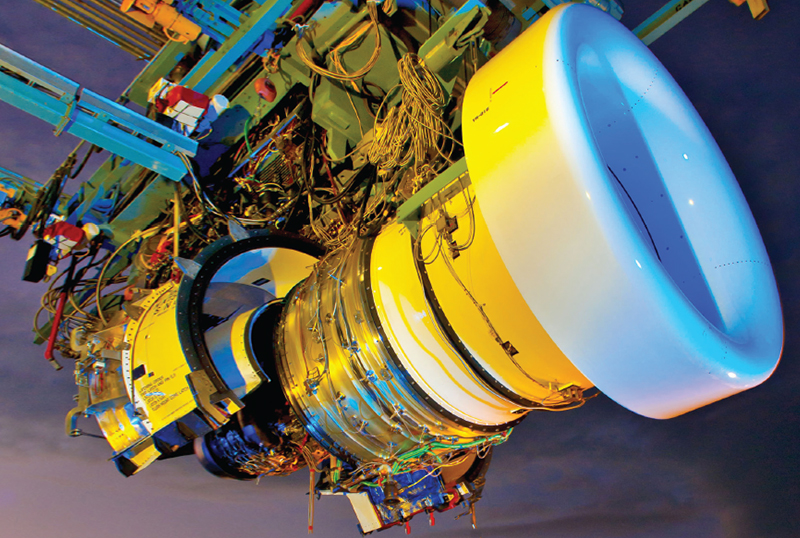

“This changes everything.” So goes Pratt & Whitney’s tagline for the PurePower PW1000G family of geared turbofan jet engines.

Pratt invested $10 billion and 20 years of R&D into the development of the new engine, which relies on a state-of-the-art gear system that separates the engine fan from the low pressure compressor and turbine.

The design allows each of the modules to operate at their optimum speeds: The fan rotates at a slow speed while the low pressure compressor and turbine operate at high speeds, increasing engine efficiency and delivering significantly lower fuel consumption, emissions and noise, according to company reports.

How much lower? The new design, considered revolutionary in the industry, boasts double-digit fuel burn reduction, a 50% reduction in noise and low emissions.

With orders in hand from Airbus, Bombardier, Embraer and Mitsubishi for some 7,000 engines totaling more than $18 billion, Pratt & Whitney’s business is about to ramp up in an unprecedented way. Production is forecast to double by 2020 - indeed the project to meet this demand is known internally as the “Ramp Up”.

While the Ramp Up changes everything for Pratt’s top line, meeting the demand for that many engines over the next five years will also change how Pratt manages its supply chain. Jet engines are built slowly and to exacting quality standards. What’s more, the traditional aerospace supply base of critical components are small-to-mid-size businesses with limited capacity and long lead times.

A number of critical suppliers also provide parts to GE and Rolls Royce, competitors that are also looking to secure limited capacity for their operations. Doubling production over such a relatively short period means that any recovery time has been removed from supply chain processes - there is very little room for error from the standpoint of quality or delivery.

Pratt’s supply chain challenge is how to ramp up production in a way that protects its base of supply, engineers in quality and delivers the final product in a timely and economical way.

To meet that challenge, Pratt & Whitney had to develop a new supply chain strategy which included a “no single point of failure” policy, according to Sergio Loureiro, who was recently named Pratt & Whitney’s vice president of Manufacturing and Module Center Operations and was formerly the vice president of Pratt’s global supply chain.

To launch the Ramp Up, Loureiro’s team mapped and modeled its supply chain to identify as many points of failure as possible across the supply base. The team then defined the programs and processes Pratt needed to put in place to protect its cost position and capacity. The result was a four-pronged approach that included:

- long-term agreements with key suppliers to ensure the supply of parts and components (see sidebar);

- command centers in Connecticut and Canada to monitor the real-time performance of the supply chain, laying the foundation for a digital data stream across all parts and product lines;

- strategically-located regional offices across the globe that position cross-functional skills in engineering, production, quality and supply chain management. These offices serve as a resource to resolve issues for the supply base; and

- The UTC Production Part Approval Process (UPPAP), which was designed to identify and control the key variables that can affect the quality of a part before the part goes into production.

No single point of failure was devised so that nothing, including a financial problem or natural disaster, would delay the delivery of engines as required by Pratt’s customers.

This new model takes a proactive approach to quality and delivery times rather than a reactive approach. While Pratt still designs most of what goes into the engine, suppliers are truly part of the process from the design stage through final delivery. They meet regularly with Pratt & Whitney engineers to ensure that the design can be manufactured in production quantities or to take advantage of a specialty process that may be unique to a supplier.

“We are in their shops, working together to remove any barriers to production and anything that may affect delivery of a high-quality product to our customers,” Loureiro says.

He adds, “Pratt also leveraged its extensive knowledge in managing high-volume programs from its Pratt & Whitney Canada small engine division and pioneered a new standard work for supply management developed across UTC.”

“There are many things we can overcome, but we cannot overcome the dimension of time because this Ramp Up - it’s now…it is our reality. So we are doing an extraordinary amount of due diligence up front to remove any failure points and drive momentum,” Loureiro says of the strategy.

From Supplier to Partner

Armed with a long-term agreement from Pratt & Whitney, Polamer Precision has invested in its future and evolved from a job shop to a world-class production facility, and from a supplier to a partner.

Polamer Precision, Inc.’s new 152,000 square foot world headquarters in New Britain, Connecticut, is a testament to the strength of today’s aerospace industry. The company was founded in 1997 with 2,000 square feet of space, a few machines and a handful of employees.

The new building represents a $17 million investment, including a new ERP system, automated production equipment capable of lights out manufacturing and a three-acre solar panel farm that provides clean, sustainable energy to power the facility. Since moving in, Polamer doubled its head count from 60 to 130 employees with the potential of reaching 300 employees by 2019.

It will be put to good use by Pratt & Whitney. In late 2014, Polamer was one of the 350 suppliers to sign an LTA to manufacture engine parts and complex components for Pratt & Whitney’s geared turbofan engine. The agreement guarantees Polamer’s business with Pratt for eight years, with the potential to double the original agreement in future years.

While Polamer also supplies parts to Mitsubishi, GE, Rolls Royce and other global customers, Pratt has named Polamer’s New Britain facility a Center of Excellence for complex housings. Most of all, the agreement has provided the stability and predictability that gives a supplier the confidence to grow its capabilities. “We understand what our business will look like today, tomorrow and potentially 12 years from today,” says Chris Galik, Polamer’s CEO and president (pictured below).

“Polamer has transformed from a job shop to a full production facility that is capable of supporting our customer’s requirements, as well as the potential to expand our customer base. We’re planning on Pratt taking the majority of that production.”

Galik describes his company’s work with Pratt as an example of the evolution from supplier to partner. Polamer became involved in the development of the geared turbofan engine four years ago, identifying the project as one that it could not afford to miss out on if it wanted to be a player. Being involved in this program is essential to our success. “The geared turbofan program has forced the entire aerospace industry to rethink its approach to engine power and efficiency,” he says.

Being part of the team has been a collaborative process. During the design process of parts, Pratt & Whitney’s engineering teams met continuously with Polamer’s engineers to ensure that the new parts could be manufactured efficiently, economically and on time. “There’s a thousand ways to approach any of these parts,” Galik says. “By bringing Pratt’s design team in here, we could jointly establish changes that ultimately led to cost reductions when it came time to manufacture the parts.”

Pratt & Whitney’s team also exposed Polamer to best production practices from other industries, such as the way parts and work flow through a lean environment in the auto industry. “We are going to a cellular approach to manufacturing, where parts move from machine to machine, and, with automation, we’re introducing a lights out concept where the equipment is running on its own,” he says. “That came about from working with Pratt.”

Perhaps the most important facet of the transformation involves the relationship between Polamer and Pratt & Whitney, as the engine manufacturer looks more than ever to its supply base for support. “Pricing and delivery will always be important,” Galik says, “But Pratt is listening to our suggestions and we’re collaborating on engineering changes. This is not a supplier-customer relationship, it’s more like a partnership.”

This Is How They Did It at Pratt & Whitney

Protect the Base

A jet engine like the geared turbofan has between 2,000 and 2,500 parts. While many are consumables, like nuts and bolts, the new engine utilizes a number of new materials, new technologies and new production processes which may be in limited supply.

As such, Pratt & Whitney is not only in a war for market share but also for capacity. At the outset, Pratt decided that it would continue to design the majority of the engine.

Once that decision was made, Loureiro says the fundamental question for the supply chain was: What parts will Pratt manufacture versus buy from suppliers? If it’s a buy, which suppliers will produce the part and what will be the conditions or governance of the contracts, including the limits of liability, quality requirements and delivery requirements. Finally, how can Pratt lock up the supply it needs to meet demand.

In 2013, Pratt launched an initiative to negotiate long-term agreements with key suppliers; to date, the company has executed contracts with some 350 suppliers valued at $23 billion, with plans to execute contracts with another 200 suppliers by the end of 2017. The initiative will cover 90% to 95% of the part numbers that go into an engine. “First and foremost, the goal is to secure capacity,” says Craig Musson, the director of strategic sourcing who is spearheading the initiative. “Beyond that, I want to have more than one source where required to mitigate risk.”

The first step in the undertaking was to form a separate strategic organization staffed with handpicked personnel from inside and outside Pratt & Whitney as well as contract attorneys and paralegals. The new staff was then organized into teams that represented the dozen or so categories of parts that go into an engine. Each team was paired with a contract attorney. Before going into the field, the teams went through rigorous negotiation training.

In addition, contract processes were standardized wherever possible so that one LTA looked the same across the parts categories. Musson says the start-up process took about three months and a considerable amount of internal alignment across all functional groups.

In addition to terms like price and delivery, the LTA’s incorporate supplier performance through the inclusion of operational agreements, such as how many weeks of buffer inventory a supplier will keep on hand, and capability requirements that involve engineering in the sourcing activity. The goal is to design parts that meet the engine requirements and can also be produced to meet cost requirements.

“In the past, we may have categorized a part as a machined part,” says Darren Bicknell, the director of supplier performance. “For this program, we have 52 different families of parts because machining a case is different from machining an oil nozzle.”

Once a contract is in operation, suppliers are scored against delivery and quality goals aimed at achieving the perfect part every time. To reach the Gold Level in Pratt & Whitney’s supplier program, suppliers must meet 100% on-time delivery for a sustained 12 months with fewer than 250 parts per million defects. Gold suppliers are re-assessed every 18 months. For those that achieve Gold status, there are incentives, such as more favorable payment terms.

Just as Pratt has had to invest in new equipment and automation for the Ramp Up, so have suppliers, many of whom are located in Connecticut and have been supplying parts to Pratt for 30 years or more. While Pratt is not directly investing in its suppliers’ operations, many have been able to use their LTA’s to obtain low interest loans from the state of Connecticut to make those investments.

Command Centers: The Digital Supply Chain

The Ramp Up created the opportunity to further the digitization of Pratt & Whitney’s supply chain. And while “the digital supply chain” has become one of those buzz words that is difficult to define, it has a specific meaning to Loureiro.

“I want to understand the WIP position of every part of every engine, and all the inspection features, from the time we place a purchase order until we put it in an engine that is delivered to the customer. Then I want the reliability and repair data once it’s in service so that we can follow the performance and movement of that part across the entire life cycle.”

At present, he adds, Pratt & Whitney is tracking the movement of more than 45,000 parts a day through Command Centers in Longueuil, Canada, and East Hartford, Connecticut, which is still scaling up. A third Command Center will go live in Poland later this year.

The aim of the centers, according to Bicknell, the director of supplier performance, is to get real-time visibility into the supply chain from the flow of raw material to the supplier and the supplier’s production and logistics processes. Think of these flows as the pulse of the business.

The tracking process begins when demand is created through Pratt & Whitney’s S&OP process and is loaded into the materials planning system. The materials requirements to meet the plan then flow through the supply chain. “Suppliers see what we will need and when as far as three years out,” says Bicknell. “We then ask them to commit to a promise date through a portal.”

Once Pratt engineers working in the field verify the suppliers’ promise dates, delivery information goes into a planning engine that identifies any potential supply issues. The system also identifies suppliers that are having issues and specific part numbers that have common root problems.

“The system becomes the repository for the history of a late event, including the root cause, when we got involved and how we worked with the supplier to accelerate delivery,” Bicknell says. “Anyone coming into the system can see what has already been done with that issue so we don’t repeat ourselves.”

Production-ready parts are shipped to a logistics center in New Hampshire operated by UPS, which is responsible for the distribution of the product to the manufacturing line. “We will be monitoring the value stream from raw material to finished good,” Bicknell says. “If there are any hiccups, we will find out about them before they become a problem in production. That’s where the tool becomes important.”

PurePower PW1000G ENGINE

The PurePower Engine Changes Everything - It’s Not The Same Old Turbofan

With 20 years of research and development, component rig testing on all major modules, extensive ground and flight testing underway, two engines in the family certified and the PW1100G-JM carrying passengers on a daily basis, the PurePower PW1000G engine with Geared Turbofan™ technology delivers game-changing reductions in: Fuel burn, Environmental emissions, Engine noise, and Operating costs.

One of the next steps in this journey to visibility is the implementation of Net-Inspect, an application that collects key product characteristic data, or KPCs, from machines on the shop floor. KPCs are characteristics of the part design that have been identified as critical by the supplier.

“We’re looking to see if there are any unexpected variations in the manufacturing process so that we can address them prior to delivery,” Bicknell says.

The target is to become aware of any deviations as early as 20 or 30 weeks prior to the promised delivery date. Pratt is also working to gain visibility into WIP and finished goods stocking levels across the supply base as part of its performance monitoring tool kit. Ultimately, the Command Centers will also track the performance of engines and parts in the field, including maintenance and repair histories.

Supplier Development

The final two components of the new strategy fall under the umbrella of supplier development: The first is the opening of strategically-located regional offices that serve as resource centers to resolve issues for the supply base, and the second is the widespread adoption of the UTC Production Part Approval Process (UPPAP), which was designed to identify and control design KPCs and process key characteristics (KCs) that can affect the quality of a part.

Both reflect an evolution from a reactive supply chain - one that deals with quality issues as they arise - to a proactive supply chain that seeks to mitigate risk by addressing quality and production issues well before parts are shipped to an assembly line.

Regional offices are located in the United States, Canada, Poland and China with another planned for Japan. They are staffed with personnel experienced in engineering, quality control and supply chain management. They are also home base for members of the Supplier Development Team. These are generalists whose key responsibility is risk management. They have the experience to recognize scheduling, planning or manufacturing issues in the supply base that they can bring back to the experts in one of the regional offices for support. Each member of a supplier development team is assigned 3 or 4 suppliers that are located within driving distance so the team member can visit them every week.

The regional offices also host training and workshops - in 2016, for instance, Pratt & Whitney plans to train several hundred suppliers around the world on how to identify potential points of failure and mitigate supply chain risk. The regional offices also host training in the UPPAP initiative, a risk mitigation program borrowed from the auto industry.

UPPAP is built around the idea that there are certain key inputs and outputs that a supplier needs to control so that every part comes out of the process in perfect condition. “If a supplier can demonstrate that they can control the key inputs and outputs, they won’t have to spend the non-value-added time associated with making non-conforming product, which just adds to the cost of a part,” says Mary Schubert, the Pratt & Whitney UPPAP program manager.

The UPPAP program is built from the automotive PPAP concepts and requires a supplier to validate 19 elements, from fundamentals like having the right drawings and purchase orders to a demonstration that the supplier is in control and capable of consistently producing the part to the design. What’s more, the UPPAP program extends beyond finished goods to also include key raw materials that go into creating a part or component. The program is currently applied to the majority of the engine programs that are part of the Ramp Up.

One example of how the UPPAP program works together with the regional offices is on part marking approval - element 17 in the UPPAP process. “You’d think that part marking is something that’s easy to do, but most people in manufacturing aren’t proficient in it,” Schubert says. “We can connect our suppliers to part marking experts through our regional centers to address an issue.”

The paradigm shift? “Historically, we were more reactive than proactive,” Schubert says. “We’ve always required product to meet all the quality requirements, we’ve just raised the bar in the proactive identification and mitigation activity and objective evidence we review. We are focused on keeping non-conforming material from being produced in the first place. UPPAP helps the supplier ensure that only defect-free material is sent to Pratt & Whitney and subsequently an end use customer.”

Now, she adds, a supplier can’t ship parts until it demonstrates that it can meet Pratt & Whitney’s quality standards, such as UPPAP, up front.

Taking Off

Pratt & Whitney is some three years into the Ramp Up, with at least five years of strong production in front of it. The supply chain team believes it is positioned to protect its base to meet its supply and production goals. “Three years after launching this initiative, we still have opportunities for second and third sources for some parts,” Musson says. “And we now have 350 LTAs in place and can go to bed at night knowing that we have capacity and that we’re getting what I call ‘best value’ for our parts.”

Adds Loureiro: “I think we’ve taken supply chain management to a new level of depth to remove risk and protect our customers. For us, this Ramp Up, does not have the typical take off acceleration of an airplane, it feels more like a rocket, propelling Pratt & Whitney to historic new heights, and it takes an entire ecosystem of our own facilities, suppliers and partners to execute it flawlessly.

As we say to our suppliers: ‘The Ramp Up is here, get on board!’”

Related: Pratt Counters Critics of New Engine, Gets Supply Chain Suppliers Ready

Article Topics

Vantage Partners News & Resources

Samsung Asks Its Employees to Question Their Work Best Practices for Negotiating with Key Suppliers How Organizations Can Reinvent Procurement How Pratt & Whitney Is Managing Its Future Growth and Supply Chain Suppliers 20 Best Practices for Negotiating and Managing Key Supplier Relationships Why Emotional Intelligence Matters in Negotiations Negotiating & Managing Key Supplier Relationships More Vantage PartnersLatest in Supply Chain

How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? FedEx Announces Plans to Shut Down Four Facilities U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Most Companies Unprepared For Supply Chain Emergency More Supply ChainAbout the Author