The Truth About Growing Your Business in an Age of Personalized Products & Mass Customization

Unrelenting consumer demand for personalized products and experiences has profoundly challenged the day-to-day processes and priorities of executives responsible for managing supply chains in today’s increasingly complex marketplace.

Mass customization is not a new topic.

Before the turn of the millennium, the Harvard Business Review saw it coming, identifying what it called “the four faces of mass customization” in a column on operations management.

This was at the tipping point of when organizations became customer-driven, and the authors recognized the challenge inherent in this business model:

In their desire to become customer driven, many companies have resorted to inventing new programs and procedures to meet every customer’s request.

But as customers and their needs grow increasingly diverse, such an approach has become a surefire way to add unnecessary cost and complexity to operations.

That challenge notwithstanding, the intervening years have seen mass customization become a way of doing business in the digital age. As noted a few years after the HBR article in the journal Omega:

“Mass production and customization have traditionally been at the two opposite extremes of the production continuum. However, integrating these together as mass customization seems to be the practice of the present with the strong likelihood that it would be a continued trend of the future”.

Indeed, unrelenting consumer demand for personalized products and experiences has profoundly challenged the day-to-day processes and priorities of executives responsible for managing supply chains in today’s increasingly complex marketplace. The question they must answer: how to grow the business predictably in an age of mass customization?

The Journey Towards The Perfect Order

In the early 2000s, a consortium of industry associations tried to create a set of metrics to gauge the performance of the supply chain - execution both in production plants and inbound and outbound logistics - in an effort to directly tie performance of multiple activities to customer satisfaction.

This was known as the Perfect Order Index (POI), with perfect order fulfillment defined as the percentage of orders delivered to the right place, with the right product, at the right time, in the right condition, in the right quantity, with the right documentation, to the right customer.

The traditional approach of looking at separate key performance indicators often gave a false sense of good performance, and the perfect order was conceived to provide a comprehensive measure of demand fulfillment capability.

The initiative was embraced with widespread enthusiasm; companies tightened process enforcement and modified enterprise resource planning (ERP) systems in an effort to leverage the index. But once the initial effort was subjected to benchmarking, a number of problems emerged:

- Definition was a huge problem. There was no standard way of defining the POI; definitions varied from company to company, and even within companies. A lack of common definition often led to gaming the numbers, and comparative performance benchmarks showed wide discrepancies, leading to a lack of trust in the meaningfulness of POI scores.

- The collaboration required to share data across supply chains was lacking because organizations looked to their individual interest as opposed to the shared performance of the supply chain. This was a cultural issue.

- The concept was ahead of the technology at hand. There was both a lack of process control over the order fulfillment process and insufficient technology to manage the complexity of perfect order execution.

Order Execution Solutions

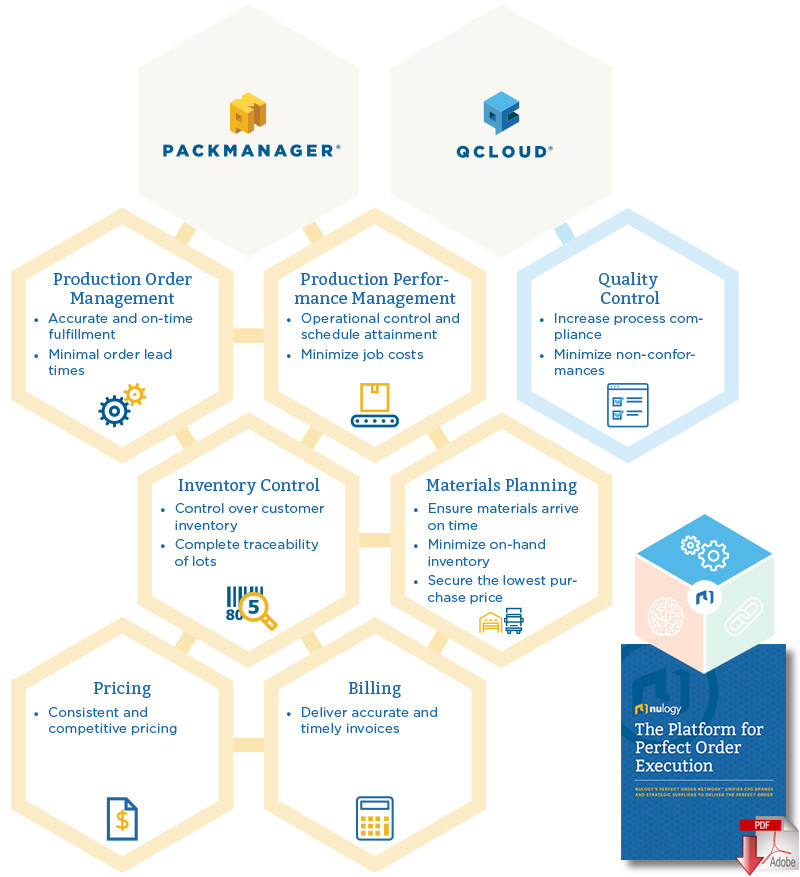

Order execution solutions help suppliers to orchestrate the moving pieces - everything from quote to ship - involved in the complex supply chain of last-mile product customization.

Three Key Business Needs in an Age of Mass Customization

As the demands of mass customization rose, these problems got worse and revealed three key areas of emerging need:

Lack of process enablement

Managing the ‘last- mile’ product customization process is highly complex due to high variability and short turnaround times. This complexity is taken to an even higher level by e-commerce, which drives customer expectations for same day/next day delivery and forces products to be made and distributed close to the point of consumption. Further, the production itself needs to be more flexible, able to produce and reconfigure quickly to accommodate rapidly changing consumer trends and the demand for innovative products.

Lack of a unified business platform

A greater reliance on outsource suppliers demands a network that can bring together multiple parties, often widely dispersed, to ensure delivery of the perfect order. Such a network needs to be provisioned by a neutral party that acts as the “custodian of care” and enables multiple supply chain partners to discover (find current capacity), interact (across systems in different organizations), and transact (send RFPs, accept proposals, deliver inventory, make payments).

Lack of real-time intelligence

Because of the velocity of change and rate of variability inherent in mass customization, tools such as predictive analytics, data science, and business intelligence are increasingly necessary to orchestrate the supply chain to cope with volatile and difficult-to-predict demand.

While these issues led many companies to abandon the perfect order as a “holy grail” and return to earlier methods of supply chain management and measurement, the fact is that today those issues no longer exist.

When One Part of a System Changes, the Whole System Must Reconfigure

In the current age, companies must face two truths: one, mass customization (and all the demands it places on the supply chain) is becoming the business model that will dominate in the years ahead (if it’s not already); two, the issues that kept organizations from realizing the perfect order after the concept was initially introduced are no longer insoluble.

Products are no longer pushed to market; they are pulled by customer demand. The emergence of cloud-based solutions provide both brand owners and their suppliers the technological wherewithal to manage the complexity of today’s to-market dynamic to deliver the perfect order that was envisioned nearly two decades ago.

They do this with three essential elements: order execution, interconnectivity, and intelligence.

Leveraging these tools, brand owners and their suppliers are able to realize the benefits that overcome the risks of consumer-driven markets to gain huge opportunities. These include:

- For brand owners: The ability to maximize partnership value and fully leverage their supplier network to take full advantage of emerging market opportunities, as well as the power to orchestrate their supply chains for maximum efficiency, minimum waste, continual improvement, and extraordinary levels of customer satisfaction

- For suppliers: The ability to showcase their performance and capabilities with reliable, standardized metrics and full visibility across supplier and customer networks, and the power to orchestrate the optimal use of resources to ensure competitive pricing and guaranteed outcomes

With today’s technology, the perfect order is no longer a “holy grail,” but rather a competitive necessity in an environment where customers no longer expect perfection, but rather demand it. That today’s solutions deliver the perfect order while driving waste out of the supply chain is even more important today when margins are increasingly thin.

As David Sculthorpe, former president of several global CPGs noted at the recent Nulogy xChange conference, “If you aren’t in pursuit of the perfect order, because that is what makes you win with the customer, then what are you in pursuit of?” Nulogy’s Perfect Order Network can help you make that pursuit successfully.

About the Author

Matthew Baggetta

Matthew joined Nulogy as their Content Marketing Specialist in 2016. He develops original research and creates educational and entertaining content to help elucidate the opportunities that digital technology has opened up in the last mile of supply chain management. Matthew holds two degrees in English (B.A. Hons, M.A.) from York University in Toronto, Ontario.

Related Article: The Supply Chain Link Both Walmart & Amazon Are Missing - The ‘Perfect Order’

White Paper

Last-Mile Supply Chain Mastery: Is Your ERP Really Up for the Job?

This white paper details how 3pls, contract packagers, and corrugators are transforming last-mile logistics with specialist software-as-a-service applications. Download Now!

More Resources from Nulogy

Article Topics

Nulogy News & Resources

How to Strengthen Your Position With Consumer Packaged Goods Building Strategic Partnerships Across North America Delivering a Positive Brand Experience Agile Customization Platform Operational Tools Nulogy’s Agile Customization Ecosystem Tools Navigating the Complex Regulatory Environment within Healthcare & Pharma Packaging Customization & Digitalization are Essential for Differentiated CPGs Product Experiences More NulogyLatest in Supply Chain

Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Ranking the Best Countries for Private Business in EMEA Frictionless Videocast: The Importance of Water at the U.S./Mexico Border with Commissioner Maria-Elena Giner, International Boundary and Water Commission Why are Diesel Prices Climbing Back Over $4 a Gallon? Plastic Pollution is a Problem Many Companies are Still Ignoring Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws 80% of Companies Still Unsure How to Best Leverage AI, Study Finds More Supply Chain