Enterprise Resource Planning Suppliers’ Expanding Supply Chain Functionality

Not only do Enterprise Resource Planning suppliers offer WMS solutions, they’re pushing the envelope for functions including e-commerce, advanced analytics, prebuilt IoT applications, and global visibility and collaboration hubs.

When it comes to “back-end” processes like taking orders, managing finances or procuring materials, most companies rely on enterprise resource planning (ERP) software.

The success of ERP at being an integrated transactional foundation have helped ERP suppliers grow into some of the biggest enterprise software companies around, with the largest vendors acquiring or building supply chain execution (SCE) software applications along the way.

Today, major ERP vendors rank as some of the leading suppliers of warehouse management system (WMS) software and other SCE solutions such as transportation management systems (TMS).

In fact, analyst firm Gartner figures that in terms of the number of new WMS deals, the leading WMS vendors have roots in ERP, even while the major “best-of-breed” SCE/WMS providers continue to do well when it comes to overall sales. Thus, in many cases, a company’s ERP vendor may also be its WMS vendor.

But ERP vendors haven’t stopped there. They’ve branched into functionality such as e-commerce, global commerce hub software and prebuilt Internet of Things (IoT) applications. These expanded offerings are in some cases changing the role ERP vendor solutions play in fulfillment operations.

Many ERP systems have WMS modules, while some of the bigger ERP vendors have also acquired “best-of-breed” WMS vendors, enhancing the products and integrating them with their ERP software.

When it comes to “core” WMS functions like receiving, putaway, picking, radio frequency (RF) device integration or even task interleaving, the WMS offerings from major ERP vendors generally can compete with best-of-breed WMS, says Dwight Klappich, a research vice president with Gartner.

“There is a still a market for best-of-breed solutions at the higher end of the marketplace - the more complex, most demanding warehouse environments,” says Klappich.

“It’s within the core WMS functions that the gap has narrowed the most. For many mid-market organizations, the ERP vendors have perfectly suitable WMS solutions.”

The integration benefits an ERP vendor can offer when it comes to multiple applications can be attractive to end user organizations, explains Klappich.

“When you talk to user companies, there is always the integration concern, but it goes beyond that to the attraction of having a single vendor solution and just knowing you are going to have common nomenclature about how your systems define things like orders. So if the WMS functionality [of an ERP vendor], is good enough, that tends to move the needle in their direction.”

Integrated E-Commerce

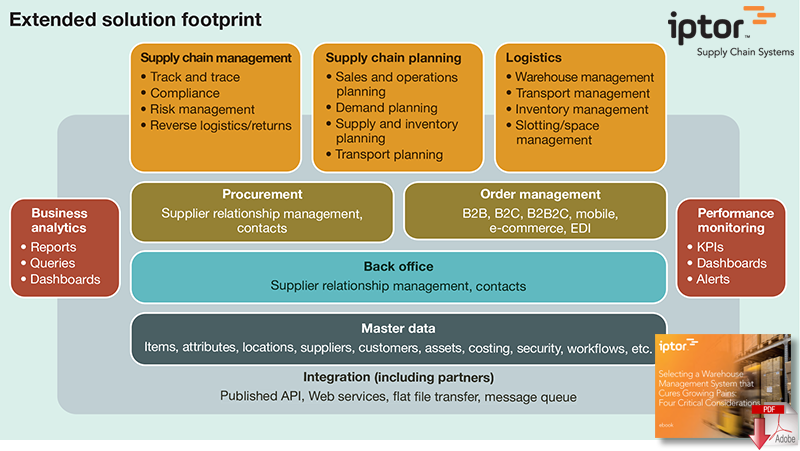

In the wholesale distribution segment, user companies need both ERP and WMS functionality, but also may want other functions including e-commerce, says Michael Wohlwend, COO of Americas for Iptor, an ERP supplier that offers WMS.

Basically, says Wohlwend, Iptor’s users are after an ERP that has vertical industry functionality and integrated WMS to execute fulfillment.

The caveat with distributors, adds Wohlwend, is that an ERP vendor’s WMS functionality needs some advanced, “Tier 1” type capabilities, such as RF device support and system-directed picking, cartonization, task interleaving or support for voice picking.

Extended functions such as e-commerce, as well as business intelligence functionality, are also part of the integrated appeal of ERP, Wohlwend says. “The reason why a customer will choose us is because we have an end-to-end solution that fits their industry and is fully integrated,” he says.

Golden Eagle Distributing, a distributor of outdoor power equipment, is a long-time user of Iptor’s ERP solution for wholesale distributors, including its WMS functionality. The company, which is based near Sacramento, Calif., and services power equipment retailers, also uses Iptor’s NetStore e-commerce solution.

The NetStore application gives a distributor’s customers access to catalogs, purchase and invoice records, as well as their specific pricing, in addition to online ordering, shopping cart functions and online payment processing. According to Mark Saks, IT manager for Golden Eagle, a key benefit of going with its ERP vendor’s e-commerce solution is that it was pre-integrated with the ERP system’s touch points for orders, inventory and warehouse management so that there would be no worries about building the integration or maintaining it over time. The e-commerce orders flow right into the ERP system’s warehouse functionality to trigger the correct pick, pack and ship processes without having to re-enter data into the ERP.

“Their [Iptor’s] software is a big part of business management functionality - from finance, to sales, warehouse and inventory management,” says Saks. “We like the fact that the e-commerce system integrates nicely with the ERP back-end processes. From an IT perspective, we never had to worry about that integration. Another benefit is that because customer e-commerce orders flow right into the ERP system without any manual intervention by our people, it becomes a timesaver for us.”

Since it implemented NetStore in 2009, Golden Eagle has seen its e-commerce orders rise from 22% of total orders the first year, to roughly two-thirds of orders today. Part of that rise is due to e-commerce becoming more of the norm in the market, says Saks, but it’s also due to the stronger features that have been added to the e-commerce implementation, such as an illustrated parts catalog functionality that lets customers click on a part or component to add it to the shopping cart.

Customers also like the self-service functions Golden Eagle can provide with NetStore, says Saks, such as paying invoices with an ACH payment process, reviewing of order history, or opening invoices and credits. The e-commerce system’s integration to ERP also shows customers what the current stocking levels are so they know product availability and have correct pricing.

“Customers appreciate the convenience factor,” says Saks. “They realize that it is a fast, easy way to place an order or look up information.”

Collaboration Tools

While ERP vendors with WMS can offer an integration benefit around these two essential applications, it’s also possible to add value by offering common tools for collaboration, user experience and analytics that span all of a vendor’s software products, explains Vishal Minocha, Infor’s global product director for supply chain solutions.

For example, says Minocha, Infor, which offers multiple ERP systems, warehouse management modules as well as a best-in-class supply chain execution suite with WMS, has a common social collaboration platform called Ming.le that works across all Infor applications and can provide alerting between ERP and WMS.

“With the Ming.le social collaboration tool, a user of one our ERP solutions can send an order to the warehouse management system and follow the status of work on that order through Ming.le,” says Minocha. “That makes it easy to collaborate on order progress and keep the end customer well informed.”

Infor also offers common analytics, document management and an integration middleware tool called ION as part of its set of “XI” tools for its systems, says Minocha. “Basically, with our XI platform, you can mash up data and information from various applications and surface it through Ming.le, as well as have powerful, common analytics that span your systems,” says Minocha.

Back in 2015, Infor acquired GT Nexus, a provider of a Cloud-based global commerce platform that coordinates commerce across partners. As a result, says Minocha, enterprises that use Infor’s ERP and WMS not only can collaborate internally, they can also use GT Nexus as a means of integrated collaboration with third parties like logistics partners, ocean freight companies and others on the GT Nexus platform.

“GT Nexus simplifies and extends collaboration to suppliers, logistics partners and the whole ecosystem of companies involved in global commerce so you can have better visibility and do what you need to do to prepare on your end with labor or inventory,” says Minocha. “You also do away with the manual intervention and lag time involved in trying to collaborate with partners through less automated means.”

Of course, vendors with ERP roots also need to constantly improve their execution applications including WMS, says Minocha. To this end, Infor’s mid-year release of its supply chain execution suite will focus on an improved visual user interface (UI) for managers. The new UI will do things like provide a “heat map” of pick activity and potential areas of congestion in a warehouse, says Minocha, making it easier for managers to keep order fulfillment work on track and reassign labor or make other changes to maintain a high level of productivity.

Folding in IoT

The biggest ERP vendors are evolving in multiple directions, including in-memory analytics, which has been a focal point for SAP with its HANA platform.

According to Markus Rosemann, the vice president who heads up SCE solutions at SAP, the main advantage of running SAP’s extended warehouse management WMS under HANA is that powerful analytics become part and parcel the WMS, rather than a separate function under a data warehouse structure.

This leads to “smarter,” actionable analytics, explains Rosemann. “We embed the analytical insight right into the operation,” he says.

Oracle, another major ERP vendor, bolstered its Cloud WMS capability when it acquired Logfire last year.

While Oracle is perhaps the most bullish vendor in the SCE space when it comes to Cloud applications, it also sees IoT and predictive analytics as technologies that can provide value.

To make IoT easier to deploy, Oracle has packaged up specific IoT applications, explains Derek Gittoes, Oracle’s vice president of supply chain management product strategy.

These IoT solutions include one called “IoT Fleet Monitoring Cloud” that can potentially send alerts to a transportation management solution.

Like its other IoT application announced earlier this year, the fleet monitoring solution handles device registration and data collection; signal analysis and interpretation; and connection to specific business processes.

“One of our targeted use cases for the fleet monitoring IoT application is to be able to take that automated signal data and the processing of that information to recognize when there is an event of interest to transportation planners and create an event we can push into transportation management,” says Gittoes.

“An example of that would be geo-fencing around DCs or other supply chain nodes, where the IoT application would detect through GPS signals when a shipment is a mile away from a DC’s dock, or 5 minutes away from a DC or a store.”

Similar to the way Oracle has packaged up IoT solutions, it also has come up with a set of what it calls Oracle Adaptive Intelligent Applications that use data science and predictive techniques, says Gittoes.

Announced last fall, the adaptive intelligent applications could look at data generated by supply chain solutions, as well as third-party and broader market data, to arrive at predictions that can help a company’s supply chain adapt to likely scenarios.

“The Adaptive Intelligent applications are a new class of applications that can be applied to supply chain operations issues,” says Gittoes.

“In logistics, you may want to take forecast information and analyze the transportation capacity that will be needed under a forecast, and while that’s certainly interesting know, what these new applications will allow is the ability to predict what the available capacity in the marketplace will be and assess what the cost of additional capacity will be.”

The Adaptive Intelligent applications leverage broader market and consumer data held in Oracle’s “Oracle Data Cloud” to arrive at better predictions around scenarios that involve data trends that sit outside the enterprise or supply chain data generated by solutions like TMS or WMS, says Gittoes. “To get at some of these predictive capabilities, you have to bring in a broader base of information than typically sits within an enterprise,” he adds.

Why the attention to functions such as better inter-enterprise visibility? As Minocha explains it, while a company can have effective ERP and WMS solutions, and solid integration between the two domains, the pressures of omni-channel and its tighter order fulfillment cycle heightens the need for real-time visibility over logistics processes so that organizations can react with execution and planning systems.

“Through better visibility to external and internal processes, manufacturers and distributors can postpone some decisions and adapt quickly to what customers need, which drives customer satisfaction,” Minocha says.

Related Article: The True Cost of Enterprise Resource Planning

Related White Papers

Selecting a Warehouse Management System that Cures Growing Pains

This eBook will help executives in warehouse management identify whether they need to upgrade their current WMS and, if so, how to select a best-value solution based on today’s competitive landscape. Download Now!

The ERP Selection Process Survival Guide

This guide provides an overview of the steps for conducting an effective and successful enterprise resource planning solution evaluation, the process can be challenging because of the level of detail that must be addressed, ensuring that key steps are not overlooked. Download Now!

Will Your Legacy ERP System Define Your Legacy?

Making the switch can help secure your business and your reputation - if you don’t pull the plug in time, your business could be on its way down a dangerous spiral of lost opportunities and profits. Download Now!

The Current and Future State of Digital Supply Chain Transformation

Executives see a large gap between the current state of digital transformation across their extended global value chains and what they expect to see in just five years from now. Download Now!

An Innovative Approach to Enterprise Software Implementations

Making the switch can help secure your business and your reputation - if you don’t pull the plug in time, your business could be on its way down a dangerous spiral of lost opportunities and profits. Download Now!

Oracle JD Edwards Cloud Computing

Choosing a deployment strategy that fits - Companies can own and manage their computing solution, yet still be involved in cloud computing by the fact that they have a private cloud for their internal application users. Download Now!

Deploying SAP EWM or WM in Your Automated Warehouse

As the market-leading enterprise resource planning system, SAP has become the go-to choice for companies seeking to streamline their operational processes to gain a competitive edge. Download Now!

More SC24/7: ERP White Papers

Article Topics

Infor News & Resources

Why the case for computerized maintenance management systems (CMMS) is so black and white Establishing the warehouse of the future through cloud-based warehouse and yard management Deliver agility and responsiveness with end-to-end visibility The Current State of Digital Supply Chain Transformation Koch Industries to Acquire All of Business Cloud Software Maker Infor Koch Industries agrees to acquire all of Infor Reverse logistics season is in full post-holidays bloom More InforLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply ChainAbout the Author