Enabling Operational Excellence & Risk Management

Investors expect companies to operate sustainably - giving new impetus for the development of processes that mitigate risk, enhance safety, and boost performance.

Many high product variety manufacturing companies have come to understand, “operational excellence is an on-going process in which companies strive to produce better results.

It has an inherent collaborative nature and typically includes participation from all parts of the organization.”

Clearly Sales & Operations Planning (S&OP) has to be an integral component of any overarching Operational Excellence strategy, but historically this process has been one where expected demand for products is balanced and synchronized with the ability to deliver the products.

To be an effective component of Operational Excellence, an S&OP process has to be able to evaluate constrained and unconstrained planning scenarios and their financial impact upon the enterprise so that all stakeholders can reach consensus.

This fact has not gone unnoticed as many leading consulting firms and software firms have introduced processes and applications to support Integrated Business Planning (IBP), a holistic approach which enables effective decision making and control over the entire organization and more closely aligns the goals of sales and operations with those of finance and shareholder objectives.

IBP is a great step forward in the maturation of S&OP, and according to an Aberdeen Research Study, enterprises that deploy integrated S&OP programs consistently outperform those companies whose approach to S&OP is more tactical and less integrated.

But here in lies the rub – to be effective, an S&OP process must be guided by financial metrics that matter, and metrics don’t come in a one size fits all category. Today, nearly every company uses unit margin to guide decision making, but for management teams of high product variety manufacturing companies, using unit margin to guide decision making will result in missed opportunities to significantly improve cash contribution.

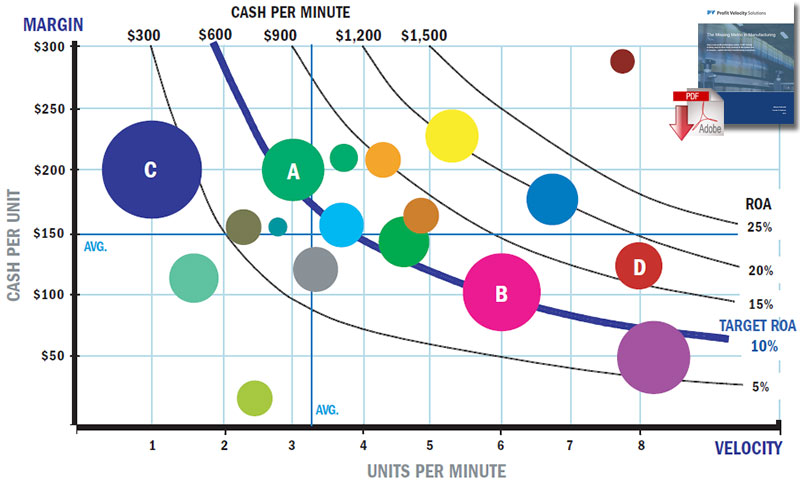

Management teams at high product variety manufacturing companies need to understand SKU and customer profitability in terms of return on assets. Why is this important? As a profit metric, unit margin represents a return on material costs or material inventory, which might be meaningful for retail businesses where their primary investment is in inventory.

But for industrial manufacturers where their primary investment is in production equipment, unit margin does not reflect the return on assets invested in making the product. When armed with the metric of cash contribution per hour of machine time (aka “profit velocity”) at an SKU or customer level, management teams can precisely measure the effectiveness of their assets, and optimize their mix of customers, products and assets to drive significant improvements in cash contribution.

Today when manufacturing management teams rely on standard profit per unit rankings to set policy on customer priority, product mix, market focus, pricing strategy, new capacity investments and the like, those policies are inherently biased in ways that actually slow down the enterprise’s overall flow rate of profit per hour. A lower average profit per hour leads to lower profits per quarter and per year, and lower returns to investors. The table above provides an example of this bias where product B has a higher margin at $300, but in fact, product A produces more cash per hour ($1,600) and is a more profitable use of existing assets.

Achieving Operational Excellence and improving shareholder returns starts with effective S&OP, but to be effective, an S&OP process must be guided by the right metrics. Using the metric of profit velocity to guide decisions, manufacturers can increase cash contribution by 3+% of revenues from their existing assets, maximize capacity, master product mix and significantly boost returns on their investors’ capital.

About the Author

Timothy Raven is the Managing Director of Profit Velocity Solutions, a provider of business analysis and planning tools for manufacturers.

Related: Supply Chain Risk and the Planning Process