E-Commerce Order Fulfillment 101: Applying Lean Practices to a Distribution Process

The rebirth of e-commerce is challenging the question "What’s taking the Distribution Center so long to implement a total lean solution?"

The automotive and manufacturing world has long used lean processes and principles in the manufacturing of goods.

Why hasn’t the distribution center applied these fundamental principles and processes in the fulfillment of orders?

In the video above, we provide a demonstration of the core principles of lean pull based principles versus the traditional push based principles in the fulfillment of orders from all channels.

The video also concludes with how to break down the barriers that are in place prohibiting the paradigm shift in processing of orders thus unleashing the efficiencies of lean operations.

Applying Lean Practices to a Distribution Process

The following content addresses the benefits of applying real-time lean practices to quality, productivity, and capacity of distribution operations and the financial impact of those benefits on a distribution network.

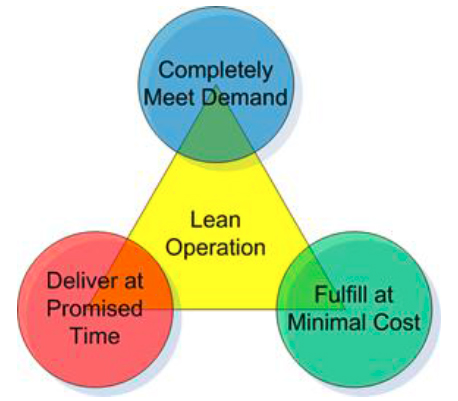

As applied to distribution, the three core values of lean are: precisely and completely deliver the demand at the required time at the minimal cost.

Lean practices provide a consistent repeatable “balance” between these core values without negatively impacting others.

The measurement of each “core value” in a distribution operation is defined by the business.

A lean process cannot be implemented without having a specifically defined means of measuring each core value.

Applying lean practices to a distribution operation can yield immense financial benefits.

The following chart summarizes the financial benefit using real-time lean practice application to 3 other facilities of similar physical size (about 1 million sq feet), similar order profiles (all D2C operations) similar order volume, similar delivery timing requirements, the same WMS, and outbound order quality requirements. One operation uses Vargo Companies real-time COFE outbound order fulfillment system, the other 3 do not.

How?

Completely Meeting Demand

COFE (Continuous Order Fulfillment Enterprise) based solutions take advantage of current conditions to “pull” orders through the fulfillment process. Completely meeting demand means delivering ONLY everything required in an expected condition.

Distribution operations have many opportunities for inventory errors, sourcing, multiple touches in the distribution process itself, each affords the chance for error. Real-time lean practices focus on immediate error detection at every possible point along the process path.

The detection of an error allows for immediate correction it also insures future orders are protected from encountering the same exception. that could otherwise go undetected.

A brief example will clarify. An order picker detects that required order items in a location are defective.

The real-time system allows the worker to flag the order and the defective item. The original order is fulfilled from an alternate location or is routed to be handled outside the normal flow path, the location is flagged for auditing and correction, new orders needing an item from the location are not selected until good inventory becomes available.

This process allows for continued processing of other orders without interruption, while allowing time for the correction of the encountered exception. With systems using this methodology, there have been reductions of personnel in exception order areas by more than one-half.

Delivery at Promised Time

As orders are “pulled” through the process, the selection of which orders to pull is done dynamically. With the Vargo lean COFE fulfillment process, orders are constantly prioritized for activation. Dynamic prioritization allows for immediate inclusion of new orders in the workflow.

Applying lean methodology minimizes work in process. Once an order is activated for processing, the processing cycle time is minimized through dynamically synchronizing and balancing labor to drive the individual orders to completion. This continuous flow process eliminates buffering. Unnecessary buffering of work extends the time to process that can adversely impact delivery time requirements. It also is waste offering no value to the process stream.

Fulfilling at Minimal Cost

Many fulfillment operations focus on the core value to the near exclusion of others. There must be a controlled balance between all three core distribution operation values.

By using a lean practices fulfillment operations can keep all core values balanced. Eliminating waste along the entire value stream creates processes that need less human effort, less space, less capital, at far less cost and fewer defects. Direct labor normally represents one of the most significant fulfillment costs.

Pull systems inherently insure maximum utilization of direct labor. At the same time, a pull system minimizes the WIP buffering demand, an additional CE cost savings.

Capitalizing on real-time decision making, lean methodologies can be used to eliminate entire processes that would have otherwise be thought to be essential.

Processes for distribution are treated identically to those for production operations, workers being constantly engaged without system created cyclic operation.

Article Topics

VARGO News & Resources

The Future of Automation in Fulfillment Centers Frictionless Podcast with Rebecca Call at VARGO How Third-Party Logistics Bid on New Proposals Designing Distribution Centers: Shifting to an Automated System E-Commerce Order Fulfillment 101: Applying Lean Practices to a Distribution Process Increasing DC Throughput with Warehouse Execution Software & Warehouse Control SystemsLatest in Warehouse|DC

Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring The Harsh Reality for Amazon and Walmart Warehouse Workers Supply Chain Stability Index: “Tremendous Improvement” in 2023 AI Not a Priority for Retailers and CPG Companies US Government Commits $6.6B to Boost Semiconductor Production Major Earthquake Hits Taiwan. How Will This Affect the Supply Chain? More Warehouse|DC