Fashion Company Desigual’s Multi-Stranded Approach to Omni-Channel

Omni-channel customers buy and return goods online or via physical stores, and expect excellent service regardless of how they receive their purchases, meeting these expectations requires inventory to be visible and available globally.

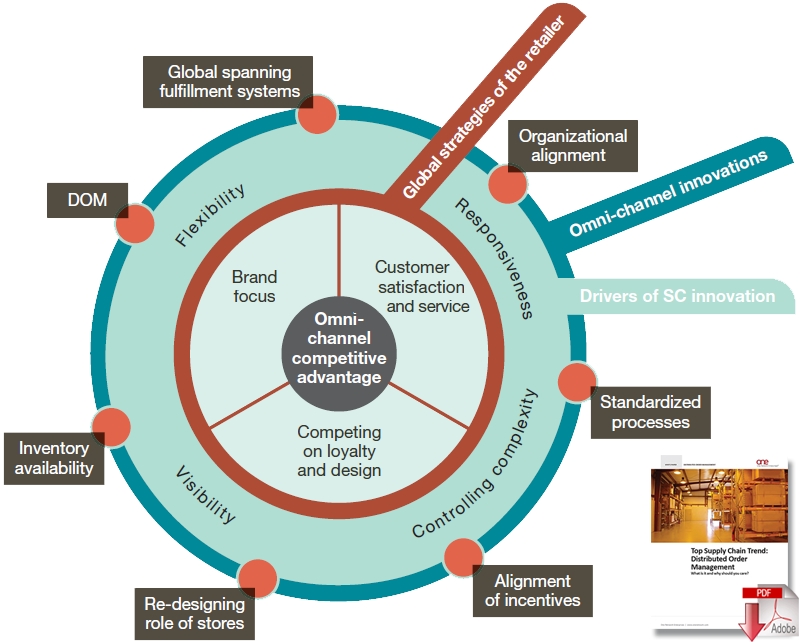

Transitioning to an omni-channel supply chain undoubtedly brings many challenges for retailers.

However, omni-channel is also a major source of supply chain innovation (see diagram below).

The journey involves multiple changes that are forcing companies to rethink the way they design, build, implement, and manage global supply chains, as well as how they relate to key supply chain players.

Fashion company Desigual is deep into its migration to an omni-channel model.

The transition is on track for a successful completion and the strategy has already spawned a number of innovative approaches that will benefit its business.

These include two areas of fundamental change.

One concerns operational activities such as inventory management, as well as broad logistics transformations that are making the company more flexible and agile.

The second area pertains to redefining Desigual’s customer relationships, again, under the premise of leveraging the company’s unique brand.

Source: Massachusetts Institute of Technology

Distinctive Style

Desigual was created in Barcelona, Spain, in 1984 by entrepreneur Thomas Meyer. The company now has nearly 5,000 employees, and in 2015 reported annual sales of 933 million euros.

From the outset, innovation was woven into the fabric of the business. Desigual is known for its upbeat, original clothing designs, summed up in the philosophy: “We believe in dressing people, not bodies.”

The company says that it has created “a world of patchwork, textures, graphic motifs and handcraft.”

These values are reflected in the Desigual product collections: Woman, Man, Kids, Accessories, Shoes, Living, Sport, and Beauty.

It’s designs are sold in more than 500 Desigual stores, 7,000 multi-brand stores, 2,700 department stores, 11,000 new category points of sale and 23 own online stores, and in more than 100 countries.

In 2015 its online store clocked some 50 million visits and sold more than 30 million garments worldwide.

Innovation in the Supply Chain

This extensive network can be broken down into a number of main channels, such as wholesalers, retail stores, franchises, department stores, e-commerce and new categories point of sales.

Each channel has its own logistics and competitive challenges.

The shift to an omni-channel strategy is partly a response to the importance Desigual attaches to being a consumer-centric company.

In addition, changing customer demands have redefined traditional purchasing practices and how customers relate to brands, especially as a result of the dramatic growth in digitalization.

Customers don’t care which division of the company owns the inventory - they just want the product whenever and wherever they desire. But the strategy has to enhance the Desigual brand. For example, products are updated more often (up to four times a season) in order to meet consumer demand.

The company’s omni-channel supply chain must support inventory replenishment systems for different combinations of online and bricks-and-mortar purchases, while supporting the brand’s unique identity and customer satisfaction:

“Desigual’s experience is based on connecting with our customers’ emotions,” states the company.

Here are some ways in which the changeover to an omni-channel retail model is spurring innovative supply chain approaches.

Aligning organizational change to the omni-channel strategy. Redefining supply chains in response to the demands of omni-channel retailing requires companies to change their organizational design.

Omni-channel is really a company project. With the support of senior management, Desigual created an omni-channel team that is involved and engaged across departments such as Supply chain, IT, Finance, HR, and across e-commerce and traditional retail commercial channels.

This cross-organizational approach is essential to developing a holistic view of the various markets - a key requirement as Desigual responds to changing consumer demand.

Even though the company is creating a supply chain geared to serving multiple channels, in the context of its customers, “we don’t have channels any more, we have one omni-channel that is focused on consumers” says a team member. This is because customers must receive the same level of service regardless of the combination of flows used to make a purchase.

Similarly, traditional organizational silos get in the way of achieving the high level of integration that an omni-channel supply chain needs. In many ways, this holistic view reflects the customer experience.

Inventory management and fulfillment. Omni-channel customers buy and return goods online or via physical stores, and expect excellent service regardless of how they receive their purchases. Meeting these expectations requires inventory to be visible and available globally.

Desigual is working hard to integrate its warehousing system with the stores that sell its wares. In the past, inventory was visible mainly at the warehouse level; now this field of vision must be expanded to stores as well.

An e-commerce order comes in via its website, and the order is allocated according to predetermined rules built into an automated fulfillment system the company has developed. Process algorithms account for the cost and service implications of different fulfillment configurations across Desigual’s global distribution network.

A primary goal is to prevent lost sales because an item is not available. This has required the company to increase global visibility in real time along its supply chain, and fine-tune its decision making when managing inventory and fulfilling orders.

Desigual is achieving these goals through an advanced Distributed Order Management system (DOM). It allows the company to manage its 16 channels and eight product categories holistically, supported by a single, real-time view of its global stocks that delivers product according to availability, proximity and delivery criteria.

For example, at the end of a season, especially during sales periods, there is typically more stock in stores than in warehouses, so it is generally better to deliver from a store during those periods.

In 2015, the company opened a warehouse in Viladecans, near Barcelona, Spain, to support the omni-channel operation and maintain the retail company’s push to improve service levels. The facility is modular so its capacity can change in line with fluctuating demand, and can store 200,000 boxes and transport 30 million units annually.

A key aspect of its distribution model is technological integration that complements the global reach of existing warehouses in Gavá (Spain), Hong Kong and in New Jersey in the United States.

“The central idea is to concentrate stock, standardize processes and become more responsive,” says a team member.

Aligning the role of the stores. Not only do Desigual’s management and operational teams have to adapt to an omni-channel way of doing business - so too do store personnel. The company has created a comprehensive training program for those stores that are part of its multi-channel network.

Each store has designated personnel for the handling of e-commerce orders. These individuals are trained to develop a multi-channel mindset. For example, they must know how to prioritize orders and set delivery times. A future practice is to offer a range of delivery times that are well within the system’s capabilities, in the knowledge that besting these deadlines scores points with the customer.

Store employees must also learn how to process returns, even for online purchases. Customers can return e-commerce purchases to stores or via a courier. When the store is the receiving point, the inventory system automatically allocates the returned product to another order if appropriate, thus facilitating product availability. The store has visibility into this process, which gives personnel valuable insights into the omni-channel process.

In order to establish a single view of the customer, regular meetings with country managers keeps Desigual attuned to cultural differences and practices in the different regions. It is rolling out the training program to more stores over a wider geographic area. To support the new role of employees, Desigual also helps stores to align their employer incentive systems with a multi-channel sales platform.

Building on the Gains

Desigual has almost completed the first phase of its omni-channel program. The transition to omni-channel has yielded some important gains. The company is more responsive and flexible, and better able to manage supply chain complexity as a multi-channel, multi-category enterprise.

These benefits will increase efficiency as the company achieves shorter lead times and more streamlined inventory management practices.

The omni-channel team will continue to refine the model. Improving service levels while reducing costs is as an overarching customer satisfaction goal.

To do this, the company plans to bring other supply chain players into the loop. An example of this approach is a “save the sales” service, that checks the availability of a product in all channels from the store. A future option is to deliver product direct from suppliers.

“There is always pressure to be innovative as every aspect of our business becomes more digital and we work to get deliveries to our customers sooner while constantly improving,” says a member of the team.

Authors’ note: We would like to acknowledge Desigual Supply Chain Group for their valuable contributions and feedback on this article.

About the Authors

Maria Jesus Saenz, Ph.D. is the director at the Zaragoza Logistics Center, MIT Global SCALE Network, in Zaragosa, Spain. She can be reached by e-mail at [email protected]. Elena Revilla, Ph.D. is a professor at the IE Business School in Madrid, Spain. She can be reached by e-mail at [email protected].

Related Article: Why “Distributed Order Management” is a Top Retail Trend and Why You Should Care

Article Topics

MIT Forum for Supply Chain Innovation News & Resources

The 50 Smartest Companies in the World Innovators Shaking-Up the Status Quo Making the Right Risk Decisions to Strengthen Operations Performance DuoSkin: Rapidly Prototyping On-Skin User Interfaces Using Skin-Friendly Materials Microsoft and MIT Turn Skin Tattoos into Touchpads Fashion Company Desigual’s Multi-Stranded Approach to Omni-Channel Elon Musk Launches $1Billion Fund to Save the World from Artificial Intelligence More MIT Forum for Supply Chain InnovationLatest in Supply Chain

Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process More Supply Chain