Creating High-Impact Supply Chain Metrics

Establishing an Effective Measurement System for the Global Supply Chain Means Asking — and Answering — Four Simple Questions.

In today’s highly global — and highly competitive — marketplace, most businesses have realized the value of investing in supply chain improvement.

Of course, whenever investments are made, there must be an analysis of their returns.

For that reason, most businesses have also created metrics that document real-world supply chain performance and track changes over time.

While performance measurement and governance are critical, unfortunately many companies either measure too much or too little with regard to the supply chain.

Worse, they measure the wrong things. Other shortcomings can include:

- Too many metrics, which creates confusion and a lack of focus

- Isolated metrics that are functional and not linked to top-level goals

- Conflicting metrics, such as high fill-rate goals, which may lead to inventory overstocks

- Outdated metrics that fail to recognize the need for agility, a crucial competency today

- Unreliable data, which creates a lack of confidence in measurement results

- A lack of ownership that leads to missed targets and subsequent finger pointing

Most businesses can improve their supply chain measurement processes by avoiding these common pitfalls — and by answering a series of four straightforward questions.

1. How Do You Define Success?

All too often, executives define high performance based on competitors’ numbers, industry benchmarks, incremental gains over last year or even what the CEO achieved in his or her last position.

But the truth is, supply chain goals should vary by organization. For some businesses, product customization is a key measure. For others, it is speed to market. Whatever the company’s unique strategic advantage, effective performance measurement begins by linking metrics to top-level corporate goals.

Over the past two decades, growth in software reporting applications has generated a huge volume of data. The expanding field of business analytics has created tools that translate those numbers into usable information. While companies have become much more sophisticated in their approach to numerical reporting, most are still not linking operations data to their long-term strategic objectives.

In order to be truly effective, supply chain measurement must create a highly structured means to identify the important issues that could keep the company from achieving its long-term goals. Executives should be able to identify the real-world impacts of improving individual processes for the extended supply chain. This allows them to define and enact metrics at the operational level that advance the highest corporate objectives.

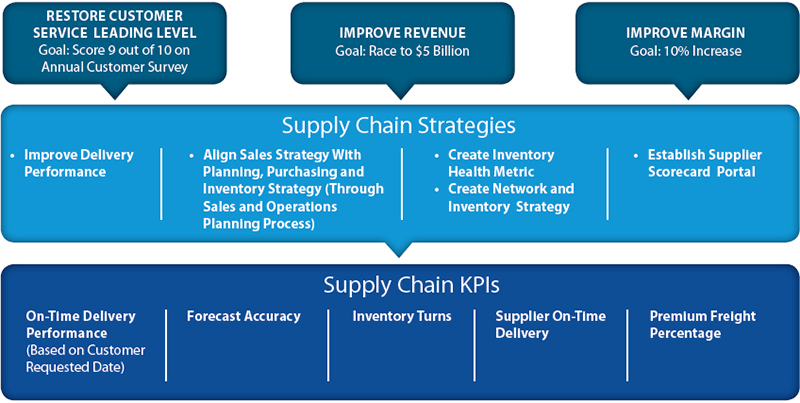

For example, as shown in Figure 1, if a top-level goal is improving customer satisfaction, then an important metric is delivery time. If increased margins are a strategic priority, then inventory management is an essential aspect of supply chain measurement. Everything must cascade from the top down.

Figure 1

Aligning Key Performance Indicators (KPIs) to Corporate Strategic Objectives Framework

As business conditions change, it is imperative to keep defining new strategic goals and corresponding supply chain initiatives. Some supply chain leaders have become masters at accomplishing this. For example, Fairchild Semiconductor — a leading manufacturer of computer components — performs an annual supply chain metrics review and assessment using a model called SCOR (Supply Chain Operations Reference).

Through this annual process, the company identifies performance gaps, defines solutions to close those gaps and also explores new improvement initiatives that support forward-looking goals.

2. Which Metrics Matter?

Figure 1 also demonstrates a third “layer” of an effective measurement system, which is defining key performance indicators (KPIs) that are aligned with the highest-level goals of the company. In defining KPIs, it is important for supply chain executives to understand the difference between a KPI and a metric.

Metrics have a meaningful context for the organization, are based on legitimate data, and lead to action or improvement. A KPI is a metric, but a metric is not necessarily a KPI. To become a KPI, a metric must directly support the overall organizational goals and strategy. It should be championed by the senior management team and also have clear meaning at lower organizational levels.

In order to ensure clarity and focus, every business should have only a handful of KPIs (Tier I metrics), though there are probably dozens of Tier II metrics. For each KPI, there should be a target performance level aimed at moving the entire enterprise forward along a strategic path.

3. How Do You Measure Progress?

Identifying KPIs is just the first step. Defining the best method to measure and track progress is equally important. It is imperative for organizations to measure progress at regular intervals in order to gauge the real impact of improvement efforts. It is helpful to establish a four-step process, as shown in Figure 2, that governs KPIs and keeps these critical metrics on track, as well as visible across the supply chain.

Figure 2

Best-Practice Framework for Key Performance Indicators (KPIs)/Metrics Governance

After KPIs have been defined based on organizational goals, clear accountability should be established by identifying Tier II metrics at the process or function level.

The best way to identify Tier II metrics is to conduct root-cause analysis on the KPIs and investigate the potential reasons for not achieving a certain target for a certain KPI in the future.

For example, if the target for on-time delivery performance based on customer request date (KPI) is not achieved, the root causes might be 1) lower safety

stocks, 2) lower 3PL delivery performance and/or 3) lower warehouse processing time. Therefore, all these measures should be considered to be part of the Tier II metrics list.

Next, dashboards and scorecards should be created — and published across the enterprise — so that progress can be closely monitored. Finally, the organization should manage a closed-loop process that ensures KPI targets are set, performance is reviewed and corrective actions are taken to stay on course.

The steel group at Timken — which provides friction management and power transmission solutions — has established itself as a leader in defining and managing performance metrics. Timken executives view supply chain metrics as a pyramid, with KPI directives getting more and more detailed and practical as they move closer to the operational level.

The company uses a balanced-metrics approach in order to ensure that metrics are not working against one another, or being considered in isolation. Timken’s top-level scorecard balances separate performance goals in the areas of throughput, inventory, on-time delivery, lead times and cost.

4. Who Is Accountable for Results?

An essential component of this four-step process is defining ownership for each KPI and metric. Lacking accountability, any supply chain improvement initiative is sure to fall short of its goals.

Owners need to work hard to guarantee that KPIs and metrics are well-defined, so that there is no dispute about results. Otherwise, managers tend to interpret progress in ways that work well for them and reflect positively on their own functional areas. This might lead to conflict. For example, if not clearly defined, the “on-time delivery performance” KPI can be interpreted by suppliers as a shipping date, while customers are likely to assume it means the receiving date.

Ownership is also key in stressing real results instead of vague activities. A metric aimed at increasing the amount of data communicated about factory orders is well-intentioned. But unless that new data is used to achieve a quantifiable financial or operational benefit — such as improved customer satisfaction or inventory reduction — gathering the data is just an exercise.

First Steps Toward Success

Today, continuously tracking and improving the way in which products are sourced, produced and distributed has become a cost of doing business in a hyper-competitive environment. While companies invest heavily in these efforts, too often they neglect to ask and answer the straightforward questions outlined here. These issues are foundational to getting true supply chain transformation under way.

Just as important is creating the closed-loop process in which key performance targets are defined, progress is monitored and corrective actions are instituted. This means scheduling regular review meetings, publishing results and keeping the energy level high around the handful of KPIs that are actually driving business success.

At the highest level of maturity, some supply chain leaders are even using KPI dashboards and early warning systems to look toward future results, and predefine the corrective actions they might need to take should the organization fall short of its KPI targets. This is the kind of anticipation and agility that can deliver real marketplace gains, especially if competitors are taking a more reactive stance.

Not every company has this kind of supply chain edge today — but, by answering a series of simple questions about their supply chain improvement efforts, they can take the first step toward leadership.

About the Author

Ehap Sabri, PhD, CFPIM, MBB is a strategic services director with JDA Software and serves as an adjunct professor with the University of Texas at Dallas.