Changing Supply Chain Strategy Will Make Apple Even More Efficient and Effective

Apple is expected to add to its assembly suppliers next year as the tech giant is set to launch multiple flagship products every year, according to analysts reports.

According to reports, Apple has shaken up its supply chain in a way that will likely put more money in the pocket of the world’s largest company by market cap.

Think about the last time you had your car repaired. When the auto shop gave you the estimate, it included a charge for parts and labor.

What you probably know is that what they charged you for those parts is not their purchase price. Your mechanic marked them up. Twice as much or even more isn’t uncommon especially on lower-priced parts.

If you’re wondering why mechanics don’t often allow you to purchase the parts yourself, it’s largely for that reason.

Apple’s manufacturers were doing the same thing. It’s manufacturing partners were not only assembling the devices, they were charged with procuring the materials as well and of course, they were marking them up. That extra layer of the supply chain was eating into Apple’s margins on each device.

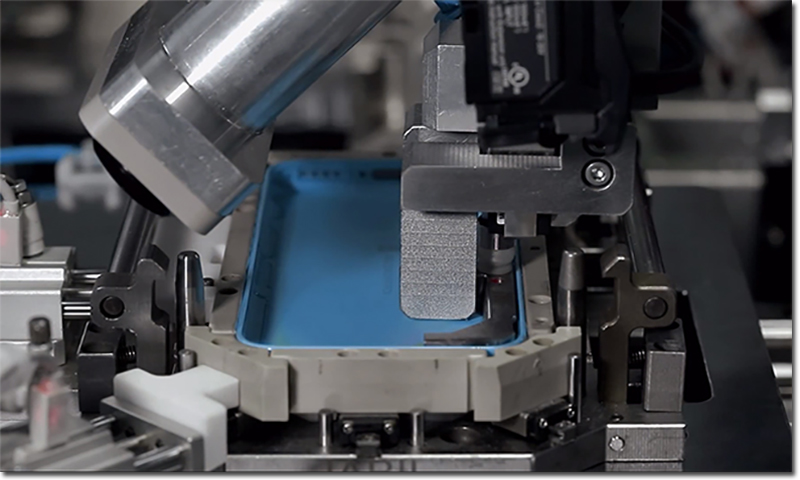

According to Digitimes, Apple adjusted its operating model with manufacturers. Instead of being responsible for both the procurement of parts and materials and production, they’re now only responsible for production.

Apple adjusts OEM operating model, say Taiwan makers

Apple has been adjusting its OEM operating model from OEMs being responsible for both component procurement and production, to purely production, according to Taiwan-based OEMs.The new strategy is expected to impact Taiwan OEMs’ profitability in the long term since some of their profits are generated from their cooperation with upstream suppliers, the sources noted.

Since more suppliers are becoming capable of supplying components for Apple’s products, the US-based vendor has recently started adjusting its upstream partners in order to preserve more profits for its products.

Apple has also agreed to let its OEMs raise quotes to maintain their gross margins, and the plan is expected to increase OEMs’ profits by 3-5%.

However such a change is expected to relieve OEMs from bearing component inventories and reducing their pressure.

That has both positive and negative ramifications for Apple’s manufacturers. On the negative side, manufacturers no longer have the ability to negotiate lower materials prices to control their margins.

On the positive side, there’s no longer the pressure of managing inventory. In the past, Apple has required its manufacturing partners to maintain certain inventory levels of all manufacturing components. This has placed added pressure on manufacturers whose strength is in production.

Second, just like the mechanic, some of the profits came from marking up the cost of parts and materials. Apple has reportedly agreed to let its manufacturers raise their prices to maintain margins. According to Digitimes, it will increase profits for Apple’s manufacturing partners by as much as five percent while also better controlling cost and quality for Apple.

Apple CEO Tim Cook is hailed as a supply chain genius, according to AppleInsider. He has systematically adopted a tighter grip on the supply chain than any time in Apple’s history. That has led to strict requirements and a more watchful eye over metrics from quality control to the treatment of overseas employees.

Despite the short supply of its gold iPhone 5S and it’s new iPad Mini, Apple sold nine million iPhone 5S and 5C phones. This was hailed as an impressive display of supply chain management.

Apple Inc. still has the trust of the market and this is a perfect ammunition to defeat competition. What the company needs is lower its cost and up the quality of its products and the market will do the rest.

Source: Tim Parker, Benzinga

View all SC24/7 coverage on “Apple”

Article Topics

SupplyChainOpz News & Resources

Is Apple Working on a Trump Contingency Plan? A Case Study of Apple Computer’s Supplier Hubs: A Tale of Two Cities The 7 Principles of Supply Chain Management Samsung’s Galaxy Note 7 Supply Chain on Fire Google Overtakes Apple as Most Valuable Company Apple Suppliers Hope to Tap Into New ‘3-D Touch’ Apple iPhone Sales Slack Says Supply Chain Leak More SupplyChainOpzLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain