Can Google’s Robots Build a New Future for US Manufacturing?

Experts say robotic manufacturing could spur economic growth, but effects on US employment remain unclear.

During a dinner with Silicon Valley executives in 2011, President Barack Obama famously asked Apple CEO Steve Jobs what he needed to do to bring iPhone manufacturing back to the US. Jobs replied: “Those jobs aren’t coming back.”

At the time, it seemed like a reasonable assertion. US manufacturing was in the middle of a decades-long decline, and American companies seemed unable to compete with the low labor and production costs in China. But that may be changing, some say, thanks to an unlikely catalyst: robots.

Recently, the Wall Street Journal reported that Google and Foxconn have been working together to develop new robotic manufacturing technologies. Experts say the partnership could have major implications for both the tech industry and the American economy, though the nature of those implications remains unclear — and an issue of intense debate.

Some see automated manufacturing as a potential boon for the US economy, a way to lure companies back to American soil with the promise of higher productivity and lower labor costs. But others fear that the push could displace the last vestiges of middle-class American manufacturing workers at a time of high unemployment and soaring inequality.

“The pace and scale of this encroachment into human skills is relatively recent and has profound economic implications,” MIT economists Erik Brynjolfsson and Andrew McAfee wrote in their 2011 book Race Against the Machine. In the book, the authors argue that technology has destroyed more American jobs at a faster pace than it’s created new ones, leading to higher unemployment and stagnant median incomes despite higher productivity levels. Although they conclude on an optimistic note, arguing that technological change will yield benefits in the long run, Brynjolfsson and McAfee say its short-term effects could be devastating for American workers.

The decline of American manufacturing is impossible to ignore; according to the Bureau of Labor Statistics, the US economy lost 6 million manufacturing jobs between 2000 and 2009 alone. But rising wages in China and increased transportation costs have spurred some companies to move manufacturing back to the US. Bolstering the country’s robotics industry, some say, would give the US a competitive advantage, particularly in the manufacturing of valuable high-end products like electronics and cars.

President Obama has repeatedly called for greater investment in high-end manufacturing, calling for a technological push “not seen since the height of the Space Race.” Earlier this year, he announced the creation of six high-tech manufacturing hubs as part of an effort to spur domestic job growth. The White House has called for a $1 billion investment to launch 15 other technology hubs, though the plan remains contingent upon approval from Congress.

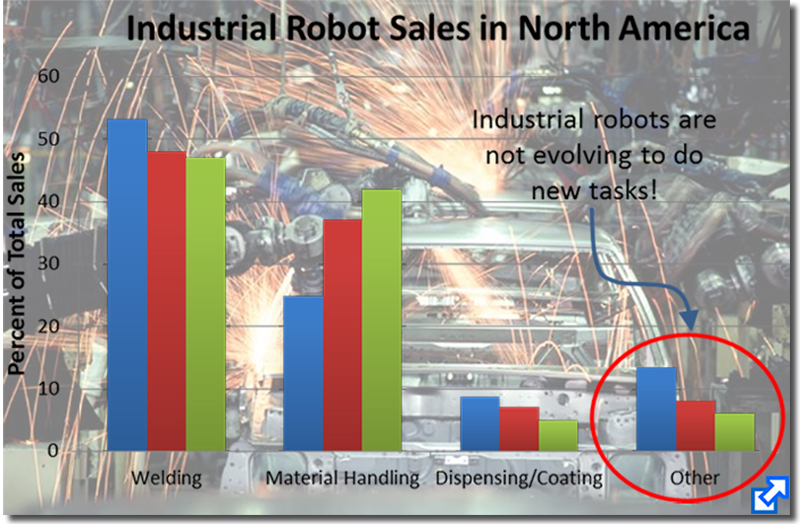

Companies like Apple and Amazon have already invested heavily in automated manufacturing, but experts say Google’s involvement could mark an inflection point in the robotics industry. Thus far, most manufacturing robots have been produced for very specialized purposes, and with little interoperability. Robert Atkinson, president of the Information Technology and Innovation Foundation, says that Google may do for robotics what it did for mobile software, creating a more interoperable platform that could be applied across various industries and at lower costs. Andy Rubin, the man behind Google’s Android operating system, has now moved to head up Google’s robotics efforts, and has reportedly been discussing new automated technologies with Foxconn Chairman Terry Gou.

Related: Google Seriously Gearing Up To Revolutionize Supply Chain Logistics

“Look at what Google did for the phone,” Atkinson says. “They basically built a cheap and easy-to-use, easy-to-distribute operating system with Android. That’s something that by and large has not been done in robotics.”

Considering their recent robot-based initiatives, it’s no surprise that Google and Foxconn would choose to collaborate. Google has spent the last several months acquiring various robotics companies, while Foxconn began deploying robots en masse at its factories in 2012. Last year, the Taiwan-based company announced plans to invest $40 million in a robot manufacturing facility in Pennsylvania, with Gou saying that Foxconn wants to be part of the manufacturing “renaissance” in the US.

It’s debatable as to whether this renaissance will actually come to fruition, though the costs of automated manufacturing are certainly coming down. A 2012 report from the McKinsey Group showed that the price of automated labor compared to human labor has fallen by up to 50 percent since 1990 — a trend that researchers expect to continue.

Shifting manufacturing away from Asia won’t be easy — especially for technology companies that rely on tightly integrated supply chains rooted in China — and the effects of automation on the American job market are still uncertain. Proponents of automated manufacturing acknowledge that some jobs may be swallowed by machines, but insist that the long-term benefits will far outweigh the losses. A robust manufacturing sector would increase productivity and fuel domestic demand, they argue, thereby creating new (albeit different) jobs for displaced workers and perhaps leveling out the US trade deficit. More domestically produced electronics and cars, for instance, would create demand for technicians and mechanics, jobs still best suited to humans.

And although the extent to which robots take hold of manufacturing remains to be seen, Atkinson and others say it’s indisputable that the sector is entering a transformative phase, and that the trade-offs involved will be far more complex than a matter of “robots versus employment.”

“That’s not really what our choice is,” he argues. “I think our choice is continued erosion of our manufacturing capabilities and the jobs that go with it, or a more revolutionary transformation.”

Source: The Verge

Robotics in the Supply Chain

The employment report released this morning by the Bureau of Labor Statistics may add to the concern that supply chain professionals will be replaced by automation in the future.

According to Ken Cotrill, a writer with the MIT Center for Transportation & Logistics (MIT CTL), that day may be closer than we think.

He notes that robots have been an integral part of the industrial landscape for many years. Advances in the technology are now making these units more flexible and versatile. The upshot from a supply chain perspective is that the new generation of factory robots makes production systems more agile and helps companies to compete in fast-changing markets.

Crossroads 2014: Dances with Robots

Robots have been an integral part of the industrial landscape for many years. Advances in the technology are now making these units more flexible and versatile. The upshot from a supply chain perspective is that the new generation of factory robots makes production systems more agile and helps companies to compete in fast-changing markets.

A key development is in “scheduling the choreography of robots,” explains Dr. Julie Shah, Head of the Interactive Robotics Group, MIT Computer Science and Artificial Intelligence Lab. Shah will explain the implications at the forthcoming MIT Center for Transportation & Logistics’ Crossroads 2014 conference, March 25, 2014, on the MIT campus, Cambridge, MA.

The movement of humans and robots on the factory floor has to be carefully choreographed. A certain distance between people and machines has to be maintained for both safety and efficiency reasons. Another constraint is that work assignments must be completed within a predetermined time; between paint applications or before the end of a shift, for example. Some tasks can only be carried out in specific locations.

Moreover, these requirements have to be met without disrupting work flows. “People must be able to move in and out of a space without the need to shut down a cell (a team of robots),” explains Shah. Similarly, hindering machine movements because of the proximity of human operators is to be avoided.

Constraints like these are not new. However, robots are now being deployed in areas that were once the exclusive preserve of humans, raising new challenges for manufacturers.

“In the past, these have not been major issues, especially when there are structured tasks for robots, but increasingly robots are being used to perform work that used to be carried out by people,” says Shah.

Also, advances in robot technology mean that many machines no longer have to be “caged” behind special protective barriers, opening up new possibilities for integrating these units into production processes.

The end result is more complex interactions between humans, machines, and the manufacturing processes that ultimately feed markets. If this “dance” can be reorganized on the fly to accommodate, say, an unexpected production changeover, then the entire operation becomes much more responsive.

“You can quickly optimize work scheduling if, say, different batch sizes are introduced,” says Shah. It is also easier to eliminate potential production delays when work schedules can be reconfigured in near real time.

It’s not difficult to imagine the supply chain implications. The explosion in online sales and the proliferation of SKUs owing to product customization are just two trends that are driving increased demand volatility. Improving the ability of manufacturing systems to pivot with shifts in demand effectively makes the end-to-end supply chain more agile.

This is what a team of researchers, including Shah, are working towards. They have developed an algorithm called Tercio that can reconfigure a work schedule involving multiple agents very quickly. For example, using traditional methods, it can typically take 30 minutes to reschedule four robots assigned with some 20 tasks. Using the new algorithm, 10 robots responsible for 500 tasks can be reassigned in 10 seconds or less in response to an external change.

“It can take a few hours to compute a new schedule even when minor problems occur, but our algorithm is the first to handle scheduling problems like these in seconds,” says Shah.

Tercio will also open up new functional horizons for robots, she maintains, reinforcing the trend towards the wider use of these machines in production systems.

The team is working with manufacturers in a number of industries to apply the algorithm in real-world production systems,” One example “is to dynamically schedule assembly operations so that the workflow is near-optimal despite variable process times,” says Shah.

Source: Supply Chain @ MIT

Download the Brief: Race Against The Machine