Brexit, the Next Big Disruption for the Supply Chain?

The prospect of Britain leaving the European Union, the so-called 'Brexit,' will be known shortly, and while most of the focus of the debate so far has rightly concentrated on the economic impact of Britain leaving; import, export and almost every aspect of the supply chain would undoubtedly be affected.

While many of the UK’s voters would likely agree they’ve heard enough already on the impacts of Brexit - whether they be economic, political or cultural – to make their decision today, the nation’s businesses are still trying to determine how dramatically a “leave” outcome would affect their operations.

Though some campaigners have chosen to turn the vote into one of ideology, the decision of whether to leave the European Union is a fundamentally economic one.

Some of the most renowned economists, from both Europe and across the globe, have weighed in on the debate, speculating on the impact Britain’s exit would have on employment within the EU and the outside world.

Though Brexit may be one of the most contentious referendums in recent memory, the effect it would have on supply chains and global volatility is impossible to ignore.

In the event that voters are in favour of leaving the EU, the UK will enter a two-year period of negotiation on the exit terms.

The event of a member nation leaving the EU is entirely unprecedented, meaning the reaction of member states is entirely uncertain.

The remaining members could decide to be accommodating and keep open trading relations, but it is more likely that they would take a tough stance on the UK in order to discourage any other waverers from leaving and precipitating a breakup of the whole union.

Upon leaving the EU, the UK will be required to establish new trading arrangements with the union. This could take different forms, such as membership of the European Economic Area, favored nation status, bi-lateral accords and World Trade Organisation rules.

The UK would also need to establish new trading rules with non-EU countries. Whatever the arrangements, any new barriers to trade will affect the structure of a supply chain and the positioning of inventory. It may precipitate a move to more local sourcing, and companies could decide that they needed more local inventories, opening new facilities and positioning finished goods stock in the different trading areas to overcome any obstacles to the movement of goods.

During the exit negotiations, international exchange rates will be sent on a roller coaster, and it is difficult to predict where they might end up. During this tumultuous period, those with supply chain insight and agility will cope best. Measures such as dual sourcing of key components and distributed manufacturing could aid in this, trading off increased flexibility and resilience against cost.

Clear visibility of the inbound supply chain will be required to correctly assess risks and determine the best strategies for mitigation. Many commentators expect the Pound Sterling to weaken against the US Dollar and the Euro, making imports of raw materials more expensive. This will disadvantage those companies with operations in the UK and could add to the case for global companies to relocate operations from the UK to the remaining EU countries.

One of the few clear results from Brexit would be a reduction in the freedom of movement in people. Many distribution operations in the UK are staffed by labour that originates from the continent, particularly within the Eastern European nations. If restrictions are placed on their ability to work in the UK a labour shortage could emerge, leading to upwards pressure on costs.

This could be worsened by the progressive increase in the minimum wage in the UK to £9 an hour in 2020. A change in the availability and cost of labour could change the site and transport cost trade-offs that lie behind the design of many supply chains, leading to fewer sites and further automation.

Investment decisions by global companies are bound to be affected as well. They will no doubt be modelling the impact of movements in costs, labour availability and trade restrictions on their supply chain before making decisions. Over time, supply chains have become increasingly extended, inter-connected and complex.

The impact of natural disasters – such as volcanic eruptions, earthquakes and tsunamis – serve as a periodic reminder of this. The UK leaving the EU would undoubtedly be added to the list of major disruptions.

With opinion polls showing uncertain results, even so close to the referendum, UK companies involved in the global supply chain are becoming increasingly concerned with the economic implications of leaving the EU. While the results of the referendum are difficult to predict, it’s clear that if Brexit is successful there will be plenty of change, though the practicalities have proven equally difficult to predict.

The disruption could go through a series of events, with some commentators predicting it could take up to 10 years for the UK to agree on new trade accords with the EU and the rest of the world.

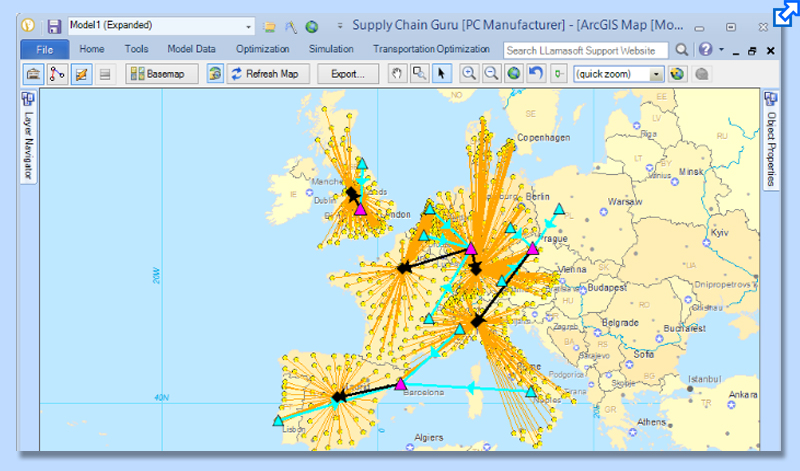

The ability to test scenarios to inform supply chain decisions will be vital. That makes the importance of analytics in supply chain design and planning absolutely critical, and those companies that don’t have the capability for rapid analytics could be left standing.

Author: Phil Gibbs is executive director, customer success, EMEA, at LLamasoft.

Why We’re Not Brexiting

Voting to remain with the EU today is a win-win across Europe.

As two members of the U.K. electorate, we both plan to vote to remain in the EU on June 23. We’d like to explain why.

At UPS, we have grown our business through our customers. Twelve years ago, we had about 3,000 employees in the U.K. Today, that has risen to 8,000.

That increase has had much to do with intra-EU trade and the free movement of goods.

To support that growth, we have also invested heavily in the infrastructure of our U.K. business with a number of new buildings and are currently building a new London hub that will help us move customers’ volume by road between the U.K. and other parts of the EU even more efficiently than we do today.

Free Movement of Goods

The single market and the free movement of goods within Europe are of critical importance to trade flows. The free movement of goods across borders within the EU has supported our growth not just in the U.K. but also throughout Europe.

We believe it is crucial that the U.K. remains an active member of the European Union.

The U.K.’s tireless commitment to trade, free enterprise and the single market have been instrumental in keeping Europe globally competitive, and the U.K. and EU are both better off with the U.K. as a full member.

UPS & the European Union

In many ways, our company has grown up with the European Union. UPS expanded into Europe in 1976, just a few years after the U.K. had joined the European Communities.

In the decades since, we’ve witnessed the remarkable transformation of Europe into a single market.

Through the efforts of government and business, more than 500 million consumers have access to the best goods and services throughout the EU, which is now the largest free trade area in the world.

If the U.K. Left…

If the U.K. left the EU, it would potentially fall outside the single market and no longer benefit from the free movement of goods.

U.K. businesses could face customs duties and barriers on their exports to other EU member states, rendering them less competitive.

The U.K. would also no longer benefit from existing and future free trade agreements negotiated by the European Commission, placing the U.K. at a disadvantage compared to today.

That is why we will be voting to remain in the EU today, June 23, 2016.

About the Authors

Andy Smith is the Transportation Director of UPS UK Limited and Peter Dunstan is the Finance Director of UPS UK Limited.

Reprinted with permission of Longitudes, the UPS blog devoted to the trends shaping the global economy.

Article Topics

LLamasoft News & Resources

Talking Supply Chain: The Truth About Digital Twins Coupa brings LLamasoft into the fold in $1.5 billion acquisition Coupa Acquires AI-Powered Supply Chain Design & Planning Leader LLamasoft for $1.5 billion Smoother execution through S&OP A Fresh Take on Supply Chain Innovation Nine Ways Food and Beverage Companies Can Use Supply Chain Design to Drive Competitive Advantage Brexit, the Next Big Disruption for the Supply Chain? More LLamasoftLatest in Supply Chain

TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month More Supply Chain