Benefits of Modernizing the Procure-to-Pay Process

Many organizations recognize the need to modernize and streamline their procure-to-pay process, and in many organizations this has taken the form of adopting e-procurement or e-sourcing technology.

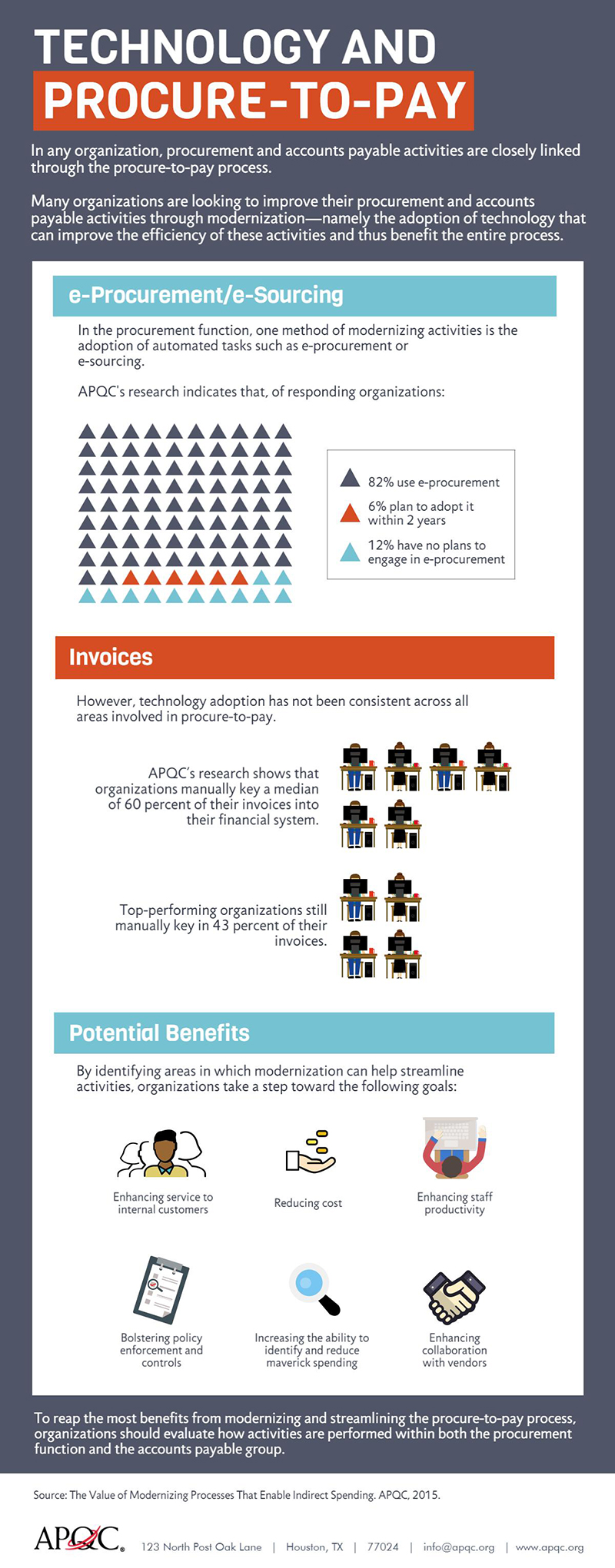

In any organization, procurement and accounts payable activities are closely linked through the procure-to-pay process.

Efficiency in both types of activities can result in clear benefits to the entire process, from the procurement function to the accounts payable area.

Organizations with a high-performing procure-to-pay process have examined this interaction and determined ways to improve it.

One way that organizations are driving improvement is through modernization, namely the adoption of technology that can improve the efficiency of these activities.

From a procurement standpoint, APQC’s research indicates that organizations that do not take steps to automate transactional activities simply cannot match the efficiency and effectiveness of those that do.

Recent research on how organizations manage the procure-to-pay process for indirect purchases reveals that many desire to modernize the process but are slowly making progress on adopting technology to support that modernization.

Automation in Procurement

In the procurement function, one way in which organizations modernize activities is through the adoption of automated tasks such as e-procurement or e-sourcing. APQC’s Open Standards Benchmarking in procurement indicates that automation has been adopted by a majority of responding organizations: 82 percent use e-procurement; 6 percent plan to adopt it within the next two years; and 12 percent have no plans to engage in e-procurement.

The primary influence of automation is the efficiency of procurement staff. Automated purchase order processing allows procurement staff to accomplish more in a shorter amount of time. This in turn can reduce staffing costs associated with purchase order processing and submitting inquiries to suppliers. It can also allow the organization to shift procurement employees from more basic tasks to more value-added activities within the procurement function.

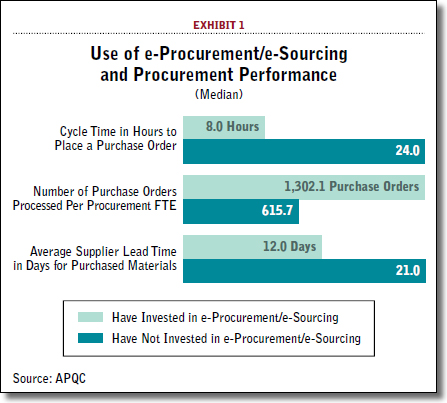

In Exhibit 1, APQC’s benchmarking data shows how organizations that automate the procure-to-pay process achieve faster cycle times and more efficient order processing.

At the median, organizations that have invested in e-procurement systems have a much shorter purchase order processing time - eight hours versus 24 hours for organizations that have not adopted e-procurement.

The systems adopted by these organizations can quickly route information to the correct individuals, which reduces the amount of time needed to place a purchase order by multiple business days.

In addition, the number of purchase orders processed per procurement full-time equivalent employee (FTE) is significantly higher among organizations using e-procurement systems.

As shown in Exhibit 1, organizations investing in e-procurement process more than twice as many purchase orders at the median as organizations that have not invested in these systems.

Along with shorter purchase order cycle times and more purchase orders processed per FTE, organizations with an automated procure-to-pay process have shorter supplier lead times.

As also shown in Exhibit 1, there is a nine day difference between the two groups of organizations at the median in the average supplier lead time for purchased materials. The increased data visibility created by e-procurement systems between organizations and their suppliers is a key contributor to this difference.

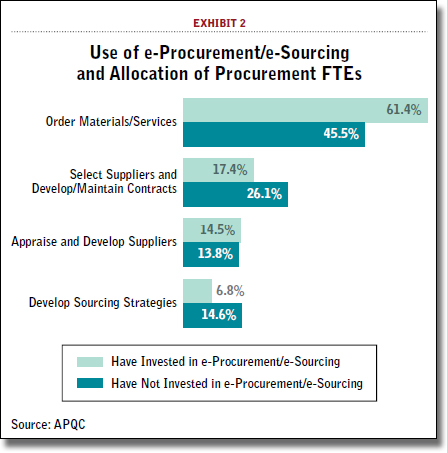

Another interesting result from APQC’s data involves how organizations using e-procurement or e-sourcing distribute the FTEs within their procurement functions.

As shown in Exhibit 2, these organizations allocate fewer FTEs to the more tactical process of ordering materials or services than their counterparts that have not adopted e-procurement.

Conversely, this group allocates about twice the number of FTEs to developing sourcing strategies than their counterparts. They also allocate a larger number of their FTEs to selecting suppliers and contracting.

These results indicate that organizations that have initiated e-procurement or e-sourcing are more focused on strategic tasks within the procurement function than organizations without this technology.

It may be that the efficiency created by the technology has enabled these organizations to focus employee efforts on strategic activities.

It is also possible that these organizations’ focus on strategy was a driver behind their adoption of technology to modernize the procure-to-pay process.

Modernization of Indirect Purchasing

Procurement is not the only function within the enterprise interested in the strategic benefits associated with modernizing the procure-to-pay process. APQC recently conducted a survey of procurement and finance professionals to learn about organizations’ plans for modernizing the purchasing and accounts payable aspects of the procure-to-pay process for indirect purchases.

The results indicate that nearly 85 percent of the survey respondents (both in the procurement and accounts payable functions) believe their procure-to-pay process would benefit from modernization efforts.

As part of this research, APQC interviewed select organizations to get a more detailed picture of what modernization efforts look like. One of the organizations was Woodward Inc., which integrates technologies into fuel, combustion, fluid, actuation, and electronic control systems for aerospace and energy markets.

Woodward was recently motivated to make improvements to its procure-to-pay process following a benchmarking effort to identify efficiency gaps. It is planning a shift from paper-based invoice management to automated invoice processing. With this new approach, Woodward will send paper invoices to a third party for scanning or to a dedicated e-mail address so that the organization can extract digital data.

Purchase order items will be sent to the organization’s ERP system for automated three-way matching. For all other items there will be an automated approval workflow. Moreover, if a purchase order item fails to match automatically via the ERP system, several e-mail workflows will facilitate communications to reconcile the issue. At the back end, Woodward will have a single archive that will be highly searchable.

Woodward is also working to implement an e-procurement system using a software-as-a-service (SaaS) solution. The goal is to have its 22 sites worldwide using standardized processes and systems, with the ultimate aim being stronger control and compliance and a better audit trail. It also wants to improve the experience for its internal customers.

For example, it will have a hosted catalog that will provide the capability to move toward negotiated pricing. If a vendor resists the notion of the e-catalog, then that supplier can join a supplier network set up by the SaaS vendor, which has Woodward’s chart of accounts so it can manage direct communications with the company’s ERP system.

Modernization Across Areas

APQC’s research indicates that many organizations recognize the need to modernize and streamline their procure-to-pay process. In many organizations this has taken the form of adopting e-procurement or e-sourcing technology.

However, technology adoption has not been consistent across all areas involved in procure-to-pay. According to APQC’s Open Standards Benchmarking in accounts payable, organizations manually key a median of 60 percent of their invoices into their financial system. Top-performing organizations have pushed that percentage down to 43 percent, but this still leaves quite a bit of room for improvement.

To reap the most benefits from modernizing and streamlining the procure-to-pay process, organizations should evaluate how activities are performed both within the procurement function and the accounts payable group.

By identifying areas in which modernization can help to streamline activities, organizations take a step toward the following goals:

- enhancing service to internal customers, reducing cost;

- enhancing staff productivity;

- bolstering policy enforcement and controls;

- increasing their ability to identify and reduce maverick spending; and

- enhancing collaboration with vendors.

The technologies that support a modernized procure-to-pay process can lead to multiple benefits. For example, e-catalogs accessible via online portals make it easy for employees to order supplies from approved vendors and at pre-negotiated prices.

Analytics software can help organizations easily analyze patterns of spending, which in turn can inform pricing negotiations. Cloud-based technology - such as the e-procurement system being adopted by Woodward, with its embedded collaboration, workflows, and analytics - can reduce the processing burden on both procurement and accounts payable employees.

As with any technology, organizations may have concerns that adoption will not result in promised cost savings or that there will be change management issues. For cloud technology in particular, organizations may be concerned about the potential for IT security risk. Organizations can address these concerns by using a pilot approach to roll out the new technology.

By testing the technology’s use for a specific task or area, organizations can lay out mitigation plans for their concerns and then expand adoption over time.

Technology and Procure-to-Pay

Efficiency in both procurement and accounts payable activities can lead to clear benefits to an organization’s procure-to-pay process.

One way that organizations are looking to increase efficiency is through modernization - in particular technology adoption.

The infographic below presents the degree to which technology is used in different parts of the procure-to-pay process and the potential benefits of modernization.

About APQC

APQC is a member-based nonprofit and one of the leading proponents of benchmarking and best practice business research. Working with more than 500 organizations worldwide in all industries, APQC focuses on providing organizations with the information they need to work smarter, faster, and with confidence. Every day we uncover the processes and practices that push organizations from good to great. Visit www.apqc.org to learn how you can make best practices your practices.

Related: Best Practices For Closing the Loop on Multi-National Transportation Procure-To-Pay

Article Topics

Amber Road News & Resources

Logistics Platforms: Ways Companies Can Win In the Digital Era Ethical Sourcing – The Business Imperative (and Advantage) How Rules of Origin Really Do Make a Difference for Sourcing Practices E2open’s acquisition of Amber Road is a done deal E2open Completes Acquisition of Amber Road Bridging the Data Gap Between Sourcing and Logistics Medical Technologies Company Remedies Complex Compliance Operations More Amber RoadLatest in Supply Chain

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller More Supply Chain