Are You Macro-Optimizing Your Supply Chain?

Survival isn’t about just responding to change, you must be willing to embrace a new supply chain model, one that relies on cooperation and collaboration versus siloed internal operations, you need to stop thinking micro and start thinking macro.

Do you remember the Blockbuster video store chain?

The company dominated the video rental market in the 90s, employing 60,000 people in 9,000 stores in the U.S.

When consumer buying habits began to change, Blockbuster ignored the obvious warning signs.

When new competitors, such as Netflix, began offering more attractive alternatives, Blockbuster scoffed at their business models and doubled down on the retail store strategy.

By 2010, the franchise was facing bankruptcy.

Blockbuster is just one of many examples of how a business failed to respond to the changing world around it and the business was reduced to irrelevancy as a result.

The equilibrium between supply and demand is constantly changing, and when companies don’t respond, they run the risk of becoming the next Blockbuster.

What does this mean for the supply chain industry? The supply chain models of yesterday no longer meet the needs of customers and new competitors are cropping up, eager to snatch market share from complacent “has-beens”.

Survival isn’t about just responding to change - you must be willing to embrace a new supply chain model - one that relies on cooperation and collaboration versus siloed, internal operations.

You need to stop thinking micro and start thinking macro.

Consumer Expectations Changing

The Amazon effect has disrupted customer expectations about the speed and visibility of goods in transit. The demand for same-day (last mile) delivery is growing every day.

Companies need to adapt to demand by modifying their supply chain processes to speed up delivery. This is a challenge, especially when dealing with fluctuations in available capacity on a monthly basis.

So how can you overcome common velocity bottlenecks? Simply put Macro-optimization.

Adrian Gonzalez Video: Stop Thinking Micro, Maximize Your Savings with Macro-Optimization

Micro- Vs. Macro-Optimization

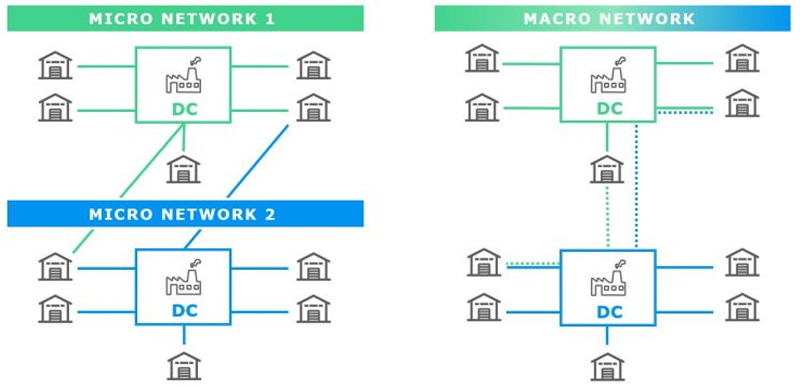

Traditional supply chain operations optimize orders and shipments through an optimization engine based on one single network. Macro-optimization involves looking at optimization opportunities available through multiple networks.

Of course, to accomplish this you need two things:

- A global trade network that allows you to have access to a broader, deeper community of other shippers, trading partners, carriers, freight forwarders, etc.

- A single-instance, multi-tenant environment for the aggregation of data.

There is a limit to the effectiveness of traditional micro-optimization because it is inherently limited to your own orders, rates and carrier capacity.

No matter how strong the optimizer is, it will always leave some portion of the shipments non-optimized because there is a finite amount of opportunity for consolidation and backhauls within a single network.

We find, on average, customers see 4 to 10 percent sub-optimal output from micro-optimization. Macro-optimization takes on that 4 to 10 percent and helps companies find new opportunities with partners within the global trade network, and encourages the sharing of resources for a better return on investment.

Real-Life Example: Shippers Sharing Capacity

Capacity constraints can be a daily issue for shippers. In a market that is characterized by capacity constraints, multiple shippers will unintentionally but effectively outbid each other for a less than truck load pick-up.

The “winning” shipper ends up overpaying, and the carrier ends up sending a truck down the road with empty space.

Macro-optimization enables shippers to share capacity on less than truck loads or on backhauls. For example, if a shipper always moves freight on a lane to Texas, but never has a return load, another shipper could use that empty capacity on the backhaul rather than contracting with a second carrier to move the same direction.

Both shippers can potentially save money, and the carrier won’t travel empty, which is good for the carrier.

Real-Life Example: Parcel Zone Skipping

A group of small parcel shippers located in one major city can use macro-optimization to pool together small parcel freight. Shippers can save time and money by zone skipping and dropping the shipments directly into the parcel carrier network, at a point much closer to the destination client.

This is simply not possible if each shipper remains locked into their own siloed operation. Macro-optimization through a global trade network unlocks the power of the network and creates value for each participant.

Embracing the Future

Are you ready to embrace the future? Macro-optimization is just one of the benefits of changing your supply chain model.

Companies that have already embraced a global trade network model are experiencing remarkable velocity. Speed and flexibility are competitive assets for companies using a Global Trade Network.

Make sure your company is prepared to win in the supply chain battleground or risk becoming the next Blockbuster.

Related Article: 3 Reasons to Walk Away From Your Current Supply Chain Model

Related White Papers

Transforming Supply Chain Strategy to a Global Trade Network Model

The technology to support a global trade network is available today, it’s just a matter of looking at supply chain design in a new way, implementing it, and moving global trade to the forefront where your supply chain becomes today’s battleground. Download Now!

Carrier Connectivity: The Critical Component of Transportation Management

In this white paper, we explore the value of building a transport management system on carrier connectivity, explain the difference between doing this yourself versus working with a vendor that has baked this connectivity into its solution. Download Now!

Article Topics

BluJay Solutions News & Resources

5 Signs You May Need a More Modern Supply Chain Solution How Supply Chains are Becoming Resilient Amid Disruptions Supply Chain 2020 Innovation Update BluJay research focuses on the need to build resilient supply chains 5 Signs It’s Time to Modernize Your Supply Chain Technology Supply Chains of the Future Boost the Power of Your Trading-Partner Network More BluJay SolutionsLatest in Supply Chain

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller More Supply Chain