Apple Watch Shows Value of Strong Supply Chains, and Opportunity in Disruption

Resilient companies with increased flexibility such as Apple can recover from supply chain disruptions more quickly than their competitors and therefore have a competitive advantage, which could potentially increase their market share.

It wasn’t long after pre-orders for Apple’s much-anticipated Watch began that trouble emerged.

Reportedly within hours of going on sale on April 10, the wait times jumped by weeks and then months.

Some models eventually were listed simply as unavailable.

A hint at one of the problems came in late April, when the Wall Street Journal reported that the Watch’s taptic engine – a key component designed by Apple that reproduces the sensation of being tapped on the wrist – was defective in models produced by AAC Technologies in China. That severely limited the Watch’s availability.

Later it was reported that a shortage of wristbands also contributed to delays, but the reason Apple was able to launch its product on time – albeit with a slow rollout – was that it didn’t rely solely on AAC for its supply of taptic engines. Nidec Corp of Japan was also supplying the key part without problems.

Now, you might think that Apple was lucky to have a second supplier, but the company didn’t become the global supply chain leader by luck. Having several suppliers for the same component is one of the strategies that companies with world-class supply chains adopt to mitigate the risk of disruptions – which can have cascading effects that not only slow a product’s release but hit the bottom line.

Ericsson learned that lesson in 2000, when a lightning bolt hit a power line in Albuquerque, New Mexico, causing a fire at a microchip plant that damaged millions of silicon wafers. Ericsson’s single-sourcing policy meant it had no other way to get the chips. Production was disrupted for months, resulting in US$400 million in lost sales.

These two incidents highlight the importance of developing reliable and resilient supply chains, in which hundreds or thousands of parts manufactured in many different countries must be ordered in the right quantities to anticipate demand and then shipped to a central point where they’re assembled to create the finished product. Just a small hiccup in this delicate dance can cause severe disruptions.

So what about a big hiccup, such as one caused by a natural disaster? Unlike Apple’s example above, which demonstrates a company-specific risk, system-wide risks can significantly disrupt supply chains across an entire industry and a wider geographic area.

Over-Reliance on a Single Supplier

In the case of the auto industry, the 2011 Japanese tsunami revealed many major automakers’ collective reliance on one plant in Japan for a type of shiny pigment used in car paints – and the costs of doing so.

The German-owned plant was located in Onahama, a coastal town that was damaged by the tsunami and was exposed to radiation from the Fukashima nuclear reactor. Car makers – including Ford, BMW and General Motors – that used the plant’s Xirallic pigment in some of their paints suffered heavily and scrambled to find new suppliers. Production in the factory was delayed for three months before normal operations resumed.

Japan’s tragic events also had a significant impact on the supply chains of many other companies, including those in the steel, electronics and chemical industries. As a result, many companies have been alarmed by the risk of supply chain disruption and how to manage it.

That disaster “made companies realize the fragility of supply chains” that had been “perfected for years to make them more efficient in order to lower costs,” according to a 2012 report by the Geneva Association (PDF), an insurance industry think tank. The report noted that despite this heightened awareness about their vulnerability, companies typically don’t do much to make their supply chains more robust because even small increases in inventory to avoid shortages can cost millions of dollars.

‘Immature’ Risk Management

That’s the trouble: when all is going well, companies don’t pay a lot of attention to their supply chains, despite understanding their importance. Although more than 90% of companies believe supply chain disruptions have a dramatic impact on their business and financial performance, only 60% pay even marginal attention to reducing risks in this area, according to a 2013 survey.

The report, by PricewaterhouseCoopers and the MIT Forum for Supply Chain Innovation, categorizes these companies as having “immature” risk processes because they mitigate risk by either increasing capacity or adding safety inventory – intended primarily to maximize profits and reduce costs.

But it’s the other 40%, deemed “mature” because they invest in developing advanced risk reduction capabilities, that tend to perform better both operationally and financially – “something for CEOs and CFOs to note,” according to the report.

Supply Chain Risk Management Now a Priority for Most Businesses

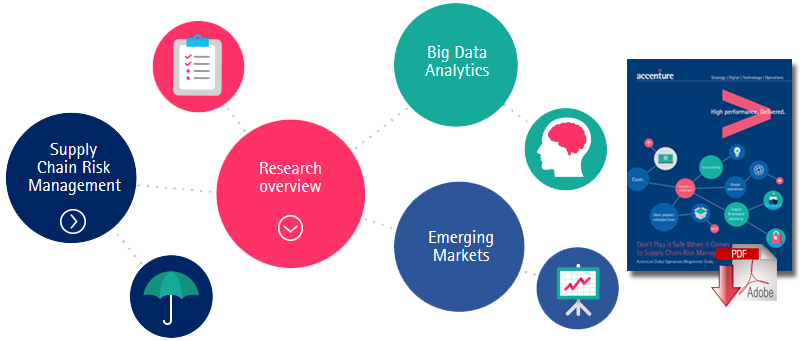

The majority of companies see supply chain risk management as important to their business, but only seven percent are generating returns of over 100 percent on their supply chain risk management investments, according to a new study by Accenture that revealed the distinct approaches followed by leaders in risk management.

- Make risk management a priority. Sixty-one percent of the leaders as compared to 37 percent of other companies make risk management a strategic imperative and recognize the importance of capabilities that help them gain greater visibility and predictability across their supply chains.

- Centralize their responsibility for risk management. Forty-three percent of leaders versus 32 percent of others had a central risk management function led by an executive in the C-suite or a vice president who oversees all of their risk management activities.

- Invest aggressively in risk management with a specific focus on end-to-end supply chain visibility and analytics. Leaders were nearly three times as likely to say they planned to boost their investment in risk management by 20 percent or more in the next two years. Furthermore, nearly 70 percent of leaders said their investments will generate a return of at least 100 percent in the next two years as opposed to 4 percent of others.

Risks and Resilience

There are many risks in every supply chain. Understanding those risks, their possible impact and their probability could help companies to mitigate them in an efficient manner.

Supply chain risks can be divided into many categories based on their impact. On one end, there are low-impact day-to-day risks such as supplier failures and volatility in demand and price. At the other extreme, there are high-impact risks such as pandemics, tsunamis and terrorism, to which companies are becoming increasingly vulnerable.

To increase their resilience, some companies conduct exercises in which a specific disruption such as cyber attack is simulated, and employee reactions are monitored and used in training. Other ways to reduce risk include increasing safety stock or capacity. These risk-mitigating processes require significant investments, which are costly and cause supply chain inefficiencies that bear fruit only if a major disruption occurs.

Flexibility is Key

So what’s a company to do? Focus on flexibility, according to MIT’s Yossi Sheffi and James B Rice Jr. “The most important step companies can take to increase their resilience fundamentally and efficiently is to increase their flexibility,“ they wrote in a 2005 article on the topic.

Flexibility not only increases resilience in case of a major disruption, but it also ensures supply chain efficiency in normal times. For example, companies can use a low-cost offshore supplier alongside a high-cost local supplier that can respond quickly to market changes. The local supplier can be used either when the offshore supplier is disrupted or during volatile periods such as when demand is underestimated.

Although it remains unclear how much flexibility is needed to mitigate supply chain risks, management professors Christopher S Tang and Tomlin Brian suggest even a risk reduction program with a relatively low level of flexibility can provide a company with significant strategic value.

In summary, resilient companies with increased flexibility such as Apple can recover from supply chain disruptions more quickly than their competitors and therefore have a competitive advantage, which could potentially increase their market share. So for resilient companies, supply chain disruption could be considered more an opportunity than a threat.

Source: The Conversation

Related: Study Highlights Pressing Need To Evolve Manufacturing Risk Management

Article Topics

PwC News & Resources

Ranking the Best Countries for Private Business in EMEA Tech Expectations Are Not Matching Reality For Many Companies Drone Technology: Clarity from Above Supply Chain Strategies under the Impact of COVID-19 of Large American Companies Operating in China Supply Chain: Your Brexit Competitive Advantage Digitization and Autonomous Driving to Halve Logistics Costs by 2030, finds PwC Study The Era of Digitized Trucking: Charting Your Transformation to a New Business Model More PwCLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain