adidas Adding Innovative Game-Changing 3D Printing Technology to Its Supply Chain

Through adidas’s obsession with helping athletes make a difference, the brand unveils Futurecraft 4D, the world’s first high performance footwear featuring midsoles crafted with light and oxygen using digital light synthesis, a technology pioneered by Carbon.

Athletic shoe giant adidas AG announced that it's partnering with venture-backed 3D printing upstart Carbon to manufacture athletic shoes with 3D-printed midsoles for the mass market.

The first shoe in the Futurecraft 4D line will be a running shoe, which customers will eventually be able to order with custom midsoles.

With this partnership, adidas sprints past athletic shoe industry leader Nike, Under Armour, and others to become the first in the industry to announce a plan with concrete timetables to produce 3D-printed shoes for the mass market.

On the 3D printing end, this partnership propels Carbon way ahead of current leader 3D Systems in the 3D-printed shoe space.

Moreover, Carbon is on track to become the tech supplier behind a momentous 3D printing industry record: Once production hits full scale, the Futurecraft 4D will be the highest-quantity mass-produced 3D-printed product ever.

Futurecraft 4D’s midsole is born out of 17 years of running data, and brought to functional reality through a pioneering digital footwear component creation process that eliminated the necessity of traditional prototyping or moulding.

With the new technology, adidas now operates on a completely different manufacturing scale and sport performance quality, officially departing from 3D printing, bringing additive manufacturing in the sport industry into a new dimension.

Traditional footwear making is slow, low tech and highly labor intensive, says Morgan Stanley, and vulnerable to volatile commodity costs, foreign exchange fluctuations, tariffs and rising labor costs in Asia.

In contrast, new technology and automation “could upend the old paradigm and speed up the footwear development process,” the analysts wrote. “The potential financial impact could be game-changing and make athleticwear stocks superior long-term investments.”

Joseph M. DeSimone, PhD, Carbon Co-Founder and CEO

“Despite the influence of technology to improve almost every other aspect of our lives, for eons the manufacturing process has followed the same four steps that make up the product development cycle – design, prototype, tool, produce. Carbon has changed that; we’ve broken the cycle and are making it possible to go directly from design to production.”

“We’re enabling engineers and designers to create previously impossible designs, and businesses to evolve their offerings, and FutureCraft 4D is evidence of that”

“Our partnership with adidas will serve as an ongoing testament to how the digital revolution has reached the global manufacturing sector, changing the way physical goods are designed, engineered, made, and delivered.”

- adidas hase strategically partnered up with Carbon to create the first performance footwear crafted with light and oxygen

- Carbon's Digital Light Synthesis enables adidas to bring the most personalized performance products from imagination into physical reality

- adidas aims to create high performance footwear with scale and speed through Digital Light Synthesis, with more than 100,000 pairs by end of 2018

Furthermore, the Morgan Stanley analysts emphasize, supply chain innovation is not a pipe dream, but rather is already in the works. adidas, for example, is set to open a stat-of-the-art “Speedfactory” in Atlanta during the second half of this year, similar to its existing Speedfactory in Ansbach, Germany.

Nike is also focusing on building proprietary technology to grab a first-mover advantage.

The analysts note that Nike in 2015 partnered with Flex, which provides supply chain and other services to equipment manufacturers, to enhance its manufacturing capabilities. Nike CEO Mark Parker said in March that the company is focused on “shifting to an event faster innovation cycle and scaling more effectively” as well as “cut[ting] our average product creation cycle in half.”

On the design front, Nike partnered with DreamWorks the same year to build “a three-dimensional digital design system that will transform its product creation process.”

All told, the analysts expect that athletic footwear's “basic cost structure” could be reduced by up to 10%, equivalent to about 500 basis points in gross profit margin savings.

Even if their competitors catch up, the analysts add, cheaper manufacturing capabilities at Nike and adidas could spell trouble for competitors like Asics, New Balance, Under Armour and Sketchers.

3D Printing and the Future of Supply Chains

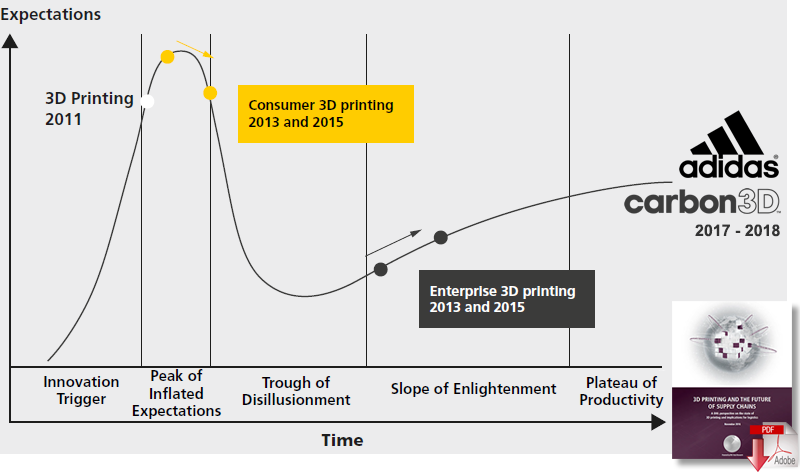

Gartner believes that enterprise 3D printing is close to a manufacturing break out and can achieve widespread adoption by 2017/18.

This is illustrated in Gartner’s annual hype cycle of emerging technologies which shows the accelerating maturity of enterprise 3D printing (see below). Over the past five years, enterprise 3D printing has successfully moved from being a nascent technology to reaching the cusp of the plateau of productivity, signaling that mainstream adoption is starting to take off.

Article Topics

Carbon News & Resources

adidas Adding Innovative Game-Changing 3D Printing Technology to Its Supply ChainLatest in Technology

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology