9 Attributes Redefining the Warehouse of the Future

The continued growth of e-commerce, last mile delivery, and warehousing as a whole are driving significant demand for industrial properties and spurring innovation in how the assets are built and utilized.

Warehouse of the Future

The increase in sophisticated technologies and attributes needed to help meet growing e-commerce demand and warehouse throughput continues to rise, with no signs of slowing down, according to a research report issued this week by Chicago-based commercial real estate firm JLL.

The 2 page report, entitled “Warehouse of the Future: 9 attributes that are redefining industrial properties today,” observes how as industrial vacancies continue to fall alongside rising operating costs and shrinking availabilities of prime land parcels, the continued growth of e-commerce, last-mile delivery, and warehousing are collectively driving significant demand for industrial properties, as well as driving innovation in terms of how assets are built and utilized.

What’s more, the firm pointed out that given tight logistics vacancy rates currently below 3%, a tight labor market that is necessitating more warehouse technologies, and a dearth of needed prime developable land, and increasing demand for last-mile distribution facilities, JLL said this has led to more heightened attention for small- and mid-sized buildings, with around 60% of new warehouse development made up of facilities ranging from 50,000-to-250,000 square feet.

The nine attributes redefining industrial properties, as per JLL’s research, include:

- Wireless technology and real-time inventory tracking: Warehouse operators are adopting new technologies to build efficiency into every aspect of the warehouse. Radio frequency identification (RFID) tags attached to each inventory item can transmit real-time data to and from the warehouse floor and inventory management applications, allowing warehouse teams to use mobile devices to track inventory from the moment it arrives.

- A hyper-connected facility: In a hyper-connected warehouse, operating systems are laid out in a highly advanced matrix to accommodate the growing mix of technologies. Today's warehouses hold bandwidth for technologies like barcoding, IoT, RFID scanning, GPS, load optimization and future technology innovations that may emerge. With this tech in place, logistics managers can quickly make and execute decisions.

- The new forklift: Forklifts, always a familiar sight in warehouses, are more connected than ever. IoT technologies can connect a warehouse operator's forklifts with their enterprise resource planning system and workers across the warehouse, shaving operations time. Some forklift manufacturers are incorporating alternative fuel systems and energy-efficient engines to reduce energy costs.

- Growing clear heights: To optimize warehouse utilization, yesterday's 24- to 26-foot ceiling height has risen to the 36- to 40-foot range today. One reason is that automated picking technology can easily reach even the highest shelves. Another is that today's lighting systems can efficiently illuminate tall spaces. Yet a third factor is the availability of fire-suppression technologies that can reach higher ceilings.

- Picking tech, picking up speed: From multilingual voice-picking and augmented reality to specialized robots, revolutionary technologies are changing picking practices. These technologies enable logistics operators to expand their labor pools by overcoming language barriers and accommodating a range of skillsets.

- Sustainability, making strides: Alternative energy and energy efficiency are no longer optional as warehouse operators bring more automation into the warehouse. Solar panels, LED lighting, cool-roof systems, thermal glass, clerestory windows, and other new green materials and innovations are leading warehouses into a new age.

- Human-centric design: As labor shortages rise in many markets, there is a growing importance on workers' quality of life in the warehouse. New features such as efficient lighting, air quality sensors and temperature control are more common as design becomes more human-centric. Improving the working environment not only benefits employee health but also reduces employee turnover and facilities risks.

- When it comes to land, flexibility is the name of the game: Industrial tenants are demanding flexibility in response to highly variable business conditions. Tenants want the option to add land and space if additional needs arise, like a seasonal rush. “Flex land” could be deployed for needs such as additional truck storage or warehouse expansion.

- Super-flat to sloped floors: The super-flat floor has long been the norm in warehouses. Although many warehouse operators continue to require exceptionally flat floors for highly precise robotic picking and racking technology, sloped floors are appearing to accommodate technologies for moving inbound and outbound shipments.

“What we are seeing in terms of how these warehouses are being set up and designed compared to five or ten years ago, when standard warehouses were all racking-based, with a picker getting on a forklift and driving around a facility to pick up goods to bring to a dock and then get shipped, is that now most facilities we are building are packed with technology and automation, where the goods sort of come to the employee,” said Rich Steger, JLL managing director and national Industrial Project Management lead, in an interview.

“Now, the employee is near the dock, and the goods come to the employee. They pick the goods out as part of a carton, and the carton goes back by itself and restores itself. It is a 180-degree shift in how the inside of the box works.”

The JLL executive explained that this pattern is driven by what is likely a permanent shift from brick and mortar retailers to online shopping.

This pattern, he said, is leading retailers to essentially invert and reconfigure their entire supply chain, including distribution networks, to being heavily e-commerce-driven.

“A lot of retailers today are building with the future in mind, with the majority of their goods being ordered online and being shipped,” he said. “It is not pallets or cartons to stores anymore. Many times instead, it is single items going to the consumer. Now, you can go online an order a single $10 item and not be charged for shipping with next-day delivery. That is a big shift.”

When asked what the biggest influence within the myriad attributes impacting warehousing operations now and into the future, Steger did not hesitate to cite automation.

The reason for that, he said, is that by necessity warehouse and distribution center operators have shifted to automation, due to the way in which goods are ordered, driven in large part by the labor shortage, which has led to a need to spend on equipment to serve their customers.

“When you look at automation, it is really all the technologies you see like wireless and robotics,” he said.

“We are now routinely looking at automated systems, which are pretty complicated and pretty imposing on a building. Around five years ago, we started seeing buildings that were serving e-commerce companies being build as customized, or build-to-suit, facilities. You can only build those so fast, and this trend is so overwhelming that technologies have been developed that are putting these automation systems inside spec [speculative] buildings in which even though the building is built already, we are still putting these highly automated systems in, so there is a lot of conversion required for a spec building, rather than just for general usage. We are spending a lot of time customizing standardized buildings to accommodate some of these systems.”

Today’s warehouse operators, according to Steger, are more comfortable with automated systems, noting that even five years ago there was resistance by them to spend a lot of money doing that type of change management and retraining employees, whereas now there is more acceptance, along with the ongoing technological advancements that have been made.

“What we are going to see is that all of distribution is going to look and feel this way, because those that don’t get there are not going to be around,” he said. “Everyone is trying to keep up with the big players or even copy them, and we some succeeding in doing so. There are a lot of companies working hard now to make this right for their future growth.”

Related: Envisioning & Planning the Future Warehouse of 2030

Planning For the Warehouse of the Future

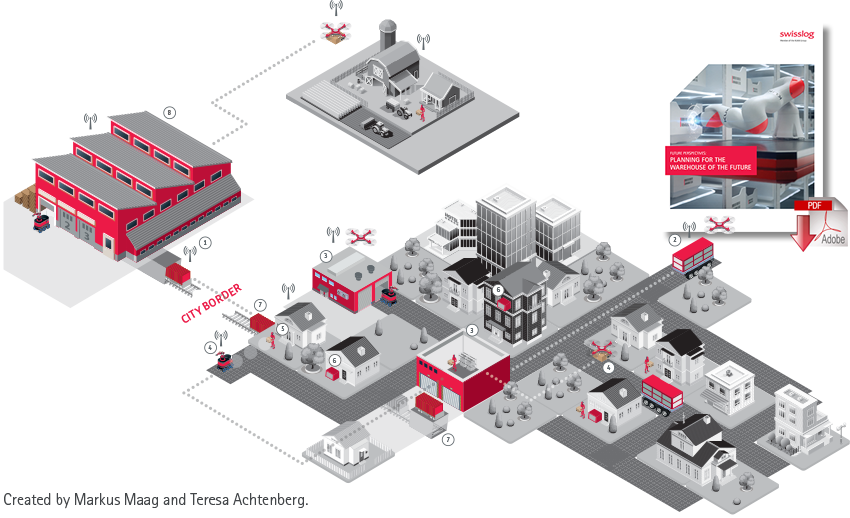

Conceptual view of distribution in the future, showing a large warehouse outside a city supporting multiple urban distribution centers with a variety of transportation options from the central warehouse to the urban DC and from the urban DCs to consumers.

Download the Paper: Planning for the Warehouse of the Future

Article Topics

Swisslog News & Resources

Walmart and Swisslog Expand Partnership with New Texas Facility Swisslog gives live demonstration of ItemPiQ latest evolution Cardinal Health at-Home Solutions automates from shelf to patient Inside Cardinal Health at-Home: Getting the right products out the door at the right time Retail distribution closes in on the customer Automated storage on the move into 2024 Swisslog AS/RS and software to be deployed to support Walmart milk processing facility More SwisslogLatest in Warehouse|DC

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Plastic Pollution is a Problem Many Companies are Still Ignoring More Warehouse|DCAbout the Author