5 Steps to Improving Your 3PL Relationships

Members of the University of Tennessee's center for Executive Education share their five steps and a series of tips to improve your outsourcing relationship right from the start.

Back in October 2010, we eagerly opened our issues of Logistics Management (LM) to read the feature article about Armstrong World Industries and how they won the coveted 2010 NASSTRAC Shipper of the Year award after bringing their outsourced transportation back in house.

As we read the case study we were actually disheartened to learn that the reason they brought the work back in house was due to a failed third-party logistics services provider (3PL) relationship.

Yes, there are some bad service providers out there. But my experience is that there are always two sides to every story. I’m sure that the service provider Armstrong parted ways with would have their own story to tell from which we could all learn a lesson or two.

However, this article is not about assigning blame, but pointing out practical steps, tips, and advice on how to improve a 3PL relationship and prevent one from becoming a failure.

As experts and outsourcing coaches, members of the University of Tennessee’s Center for Executive Education have created five steps to improve your outsourcing relationship from the start and help maintain that partnership once it gets rolling.

Over the next few pages, we’ll explore each of these five steps and provide some of our favorite tips and advice to help you improve your 3PL relationships.

Getting started

Many of the problems companies experience stem from jumping into the contract prematurely without a solid understanding of the ramifications. With this in mind, our first tip is to slow down and take the steps to get outsourcing right before you start any work.

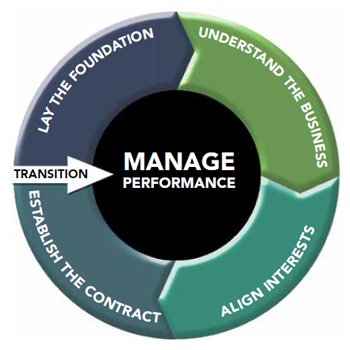

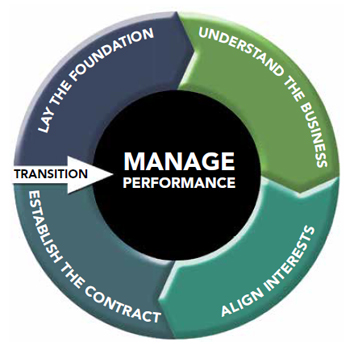

To do this properly, we recommend the five-step implementation approach that is profiled in the article Vested Outsourcing: Five Rules That Will Transform Outsourcing. The article goes into detail on each of the five crucial steps companies and service providers can take to create a successful 3PL relationship:

1. lay the foundation;

2. understand the business;

3. align interests;

4. establish the agreement or contract; and

5. manage performance.

When taken individually, these steps can offer shippers and service providers valuable insight into current operations. However, they tend to work best when implemented as a process for outsourcing by allowing companies to implement a true collaborative 3PL relationship where the company outsourcing and the service provider have a vested interest in the other’s success.

All too often, companies dust off an existing Statement of Work, rush to competitive bid, and give the service provider three months or less to transition the work—we’ve seen many that only allow for a four-week transition.

The great thing about the five-step framework is that it can be used during a request for proposal (RFP) or with an existing supplier to improve a relationship. Skipping steps usually results in a poorly conceived business outsourcing agreement or worse—a total disconnect in what the service provider is doing versus what the customer actually needs.

Step 1: Lay the foundation

The first thing a company should do before ever lifting a finger to outsource is to thoroughly understand if outsourcing is right for their operations. Management consultant Peter Drucker famously stated: “Do what you do best and outsource the rest.”

The problem is that far too many companies jumped on to the outsourcing bandwagon without realizing if outsourcing was right for them.

The October LM case study on Armstrong raised a red flag for us when we read the statement: “Managing transportation was once a core competency of Armstrong.” If managing transportation was a core competency, why did Armstrong outsource in the first place? This leads to our second tip: Don’t outsource what is core. A company should only outsource when a service provider can do the work better, faster, or cheaper.

When Armstrong’s 3PL relationship began failing early on they decided to move the work back in house. Because they brought the work back in house, we believe that Armstrong did not follow our second tip.

Step 2: Understand the business

Once a company has properly decided that outsourcing is the right choice and has done its homework associated with laying the foundation, it should take the time to establish a baseline that both benchmark the potential cost, service, or other opportunities.

Which leads us to our third tip: Understand your baseline and benchmarks before you outsource. In the Armstrong case study, one of the key decision makers said: “When we priced it out we were shocked to learn that we were less than half of what everyone else was charging.”

The article explains that the Armstrong team discovered this after they realized that their 3PL was failing. If Armstrong had done sound baseline and benchmarked cost and service they would have realized that they had an outstanding team that would not have benefited from outsourcing; in turn, they would have prevented themselves the pain of transitioning the work only to bring it back in house.

Armstrong also pointed out that “there was a failure by the 3PL to understand Armstrong’s customer requirements” and “the biggest flaw was that our 3PL took a one-size-fits-all approach…We have specialized needs, and they did not appreciate the complexity of our business.”

| Tips to better outsourcing decision making |

|

|

tip #1: slow down and take the steps to get outsourcing right before you start any work. tip #2: don’t outsource what is core. tip #3: Understand your baseline and benchmarks before you outsource. tip #4: ensure potential suppliers understand the business. tip # 5: develop clearly defined and measurable desired outcomes. tip #6: identify risks before you transition the work. tip #7: establish a pricing model with incentives that encourage service providers to put skin in the game. tip #8: develop a governance structure based on insight versus oversight. |

That sets up our fourth tip: Ensure potential suppliers understand the business. Our research and experience says that many companies are poor at stating their requirements. In fact, we often see service providers forced to “understand the business” based on a poorly written RFP and incomplete and inaccurate data.

One way to overcome this is for companies to open their doors and let service providers in to look around and explore the details of business. Let them ask for data—after all they’ll need this to run your business effectively.

Once service providers have had a chance to thoroughly understand the business, the companies and the service providers should mutually agree on cost and service goals. We call these desired outcomes. If the service provider understands the baseline costs and service levels clearly then they can feel more comfortable about signing up to achieve your desired outcomes.

And this takes us out fifth tip: Develop clearly defined and measurable desired outcomes. You are outsourcing because you have gaps in where you are today and where you want to go (your desired outcomes). It is important to make sure the service providers understand those gaps and knows what success is (your desired outcomes).

The Armstrong case study pointed out that the arrangement was not meeting Armstrong’s established costs and service goals. As researchers and educators, we love to review RFPs and poke holes in how poorly requirements are often stated and how few clearly state their desired outcomes.

Our experience is that service providers do not sign up to take on a client’s business with the intent to fail. As such, we strongly recommend that all companies take the time to work with service providers to ensure they understand the business and communicate the desired outcomes and gaps.

Step 3: Align interests

This step entails designing and documenting how a company and the service provider will work together to achieve the desired outcomes.

In basic terms, this is the part of the process where both companies should document, with as much precision as possible, how the outsourcing company and the service provider will work together to achieve the desired outcomes. It’s the first pass at the future vision for how the two companies will communicate, collaborate, and innovate together to achieve the best results.

This brings us to our sixth tip: Identify risks before you transition the work. While it’s not clear if the parties took the time to align interest, we have to assume that the parties—at least the service provider—likely did not do a proper risk assessment.

We hypothesize that if interests were aligned and a proper risk assessment was performed in the relationship, Armstrong would not have stated “it was evident pretty much from the start that it wasn’t going to work.” Obviously the parties got out of the gate on the wrong foot.

Step 4: Establish the agreement

Vested Outsourcing is based on reducing the total cost of ownership (TCO) versus simply the costs of the transactions performed by the service provider. As such, 3PL pricing models should include incentives that will be used to reward the outsource provider when they achieve the desired outcomes and TCO targets.

This brings us to our seventh tip: Establish a pricing model with incentives that encourage service providers to put skin in the game and invest in your business to close the gaps. As mentioned before, the Armstrong case study cited that “the arrangement was not meeting Armstrong’s established costs and service goals.”

One approach they could have taken was what we call a “fee at risk” pricing model. This is when a service provider charges below market rates for service—but then is rewarded with incentives for delivering results against the desired outcomes. The more successful both parties are, the more profit the service provider makes, often two to three times market rates. A true win-win because the companies become vested in each other’s success. The more successful the company is, the more success the service provider is.

Step 5: Manage performance

This is a most crucial step around which the other steps revolve. Outsourcing is not a “throw it over the fence” business process. Neither should it be an exercise in micromanagement.

Our eighth tip helps to make this clear: Develop a governance structure based on insight versus oversight. A sound governance structure outlines how the business will be managed, not just the service provider. The service provider is in essence an extension of the firm with regards to the work they provide.

If you have picked a service provider you trust and it is aligned with your interests, we find it’s often futile to micromanage the service provider. We often refer to this as a “junkyard dog” syndrome because the company outsources and then leaves in place employees who watch over and guard the old processes that have been in place for years. We hypothesize that this may have been the case in the Armstrong relationship, as the case study notes that they kept four people in place to manage the service provider’s 10 employees.

Coming full circle

The lines of demarcation between doing outsourcing effectively and doing it ineffectively can get a little blurry. As such, instead of drawing a line in the sand we promote an integrated “full circle” approach that includes the five steps we have outlined above.

We believe that even though Armstrong World Industries was the winner of the Shipper of the Year award, we’d have to give both Armstrong and their service provider a failing grade on their ability to outsource effectively. Even if the service provider was 100 percent at fault, we believe an outsourcing failure is a failure.

Article Topics

Vested Way News & Resources

Enhance the Value of Your Supply Chain Supplier Relationships Unpacking Sourcing Business Models: 21st Century Solutions for Sourcing Services Telia and Veolia: From Supplier to Strategic Partner How Dell and FedEx Supply Chain Reinvented their Relationship Case Study: McDonald’s Secret Sauce for Supply Chain Success McDonald’s “Secret Sauce” for Supply Chain Success Selecting and Managing a Third Party Logistics Provider More Vested WayLatest in Transportation

Talking Supply Chain: Doomsday never arrives for Baltimore bridge collapse impacts Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Nissan Channels Tesla With Its Latest Manufacturing Process Why are Diesel Prices Climbing Back Over $4 a Gallon? Luxury Car Brands in Limbo After Chinese Company Violates Labor Laws The Three Biggest Challenges Facing Shippers and Carriers in 2024 Supply Chain Stability Index: “Tremendous Improvement” in 2023 More Transportation